Low-energy-consumption and high-decrement-rate perishable garbage treatment process

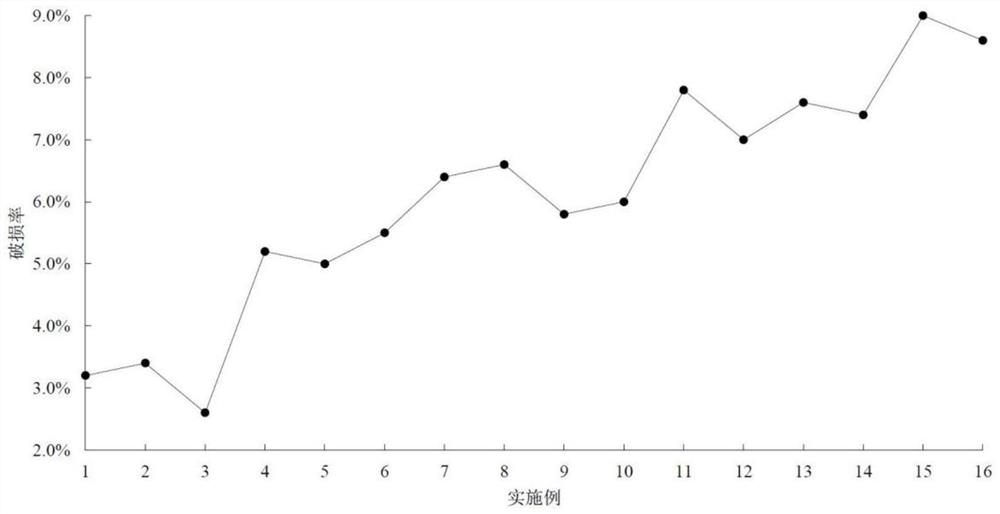

A technology of bacterial species and content, applied in microorganism-based methods, immobilized on or in inorganic carriers, immobilized on/in organic carriers, etc. The problems of low rate and product value, large investment in biogas power generation and treatment projects, etc., achieve the effects of operator and employee friendliness, excellent mechanical strength, low breakage rate and low deformation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

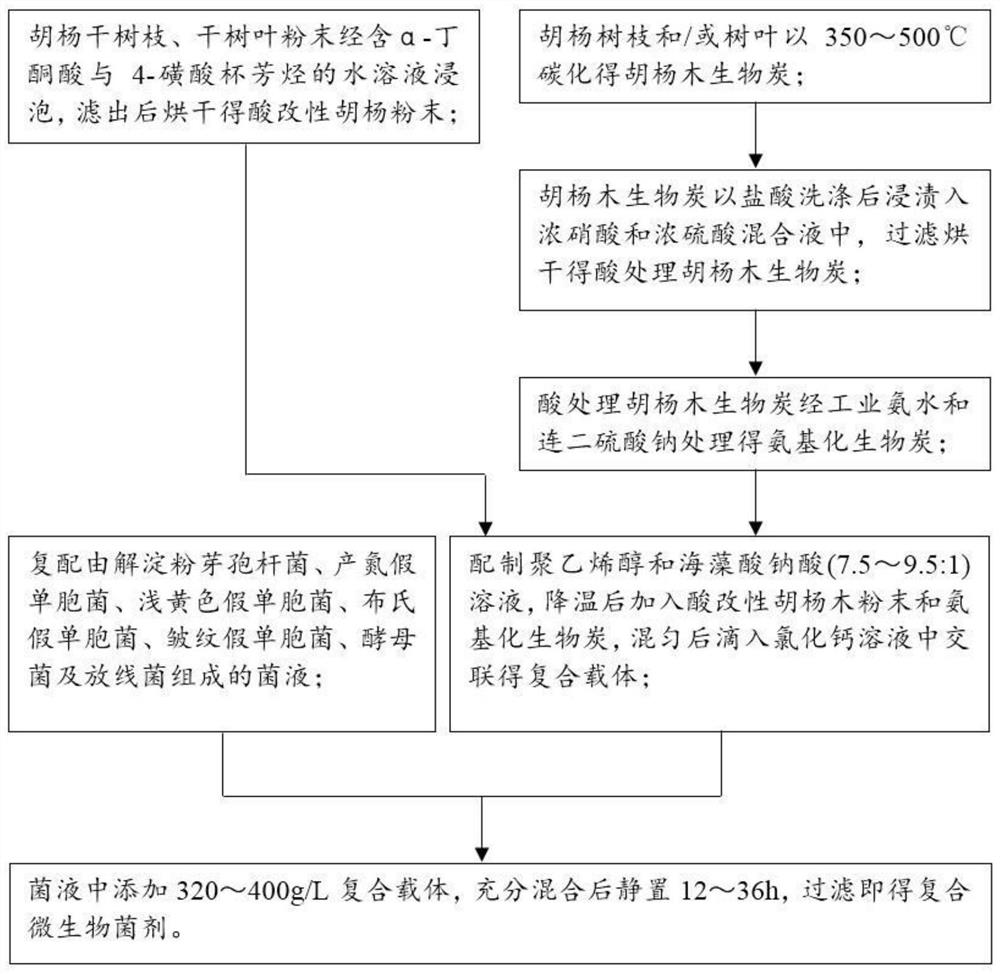

Method used

Image

Examples

Embodiment 1

[0062] Embodiment 1: a kind of composite microbial bacterial agent:

[0063] 1) Prepared with 1.5×10 9 cfu / mL Bacillus amyloliquefaciens, 1.7×10 9 cfu / mL Pseudomonas azogenes, 1.5×10 9 cfu / mL Pseudomonas flavum, 1.5×10 9 cfu / mL Pseudomonas brucelli, 1.4×10 9 cfu / mL Pseudomonas rugosa, 1.4×10 9 cfu / mL yeast and 1.5×10 9 cfu / mL actinomycetes bacterial liquid;

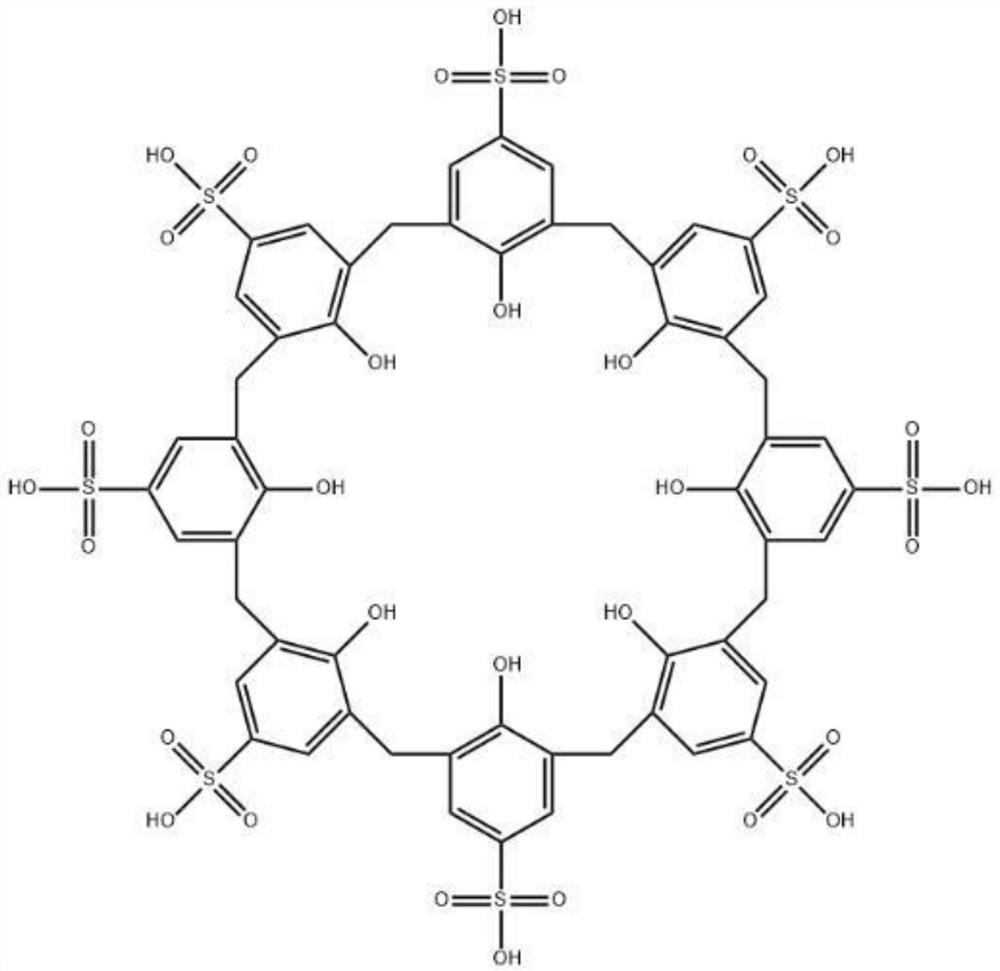

[0064] 2) Take 100g of 60-mesh Populus euphratica dry branch powder, put it in 2000mL aqueous solution containing 1% α-butanuonic acid and 0.8‰4-sulfonic acid calixarene, stir and disperse and modify at 120r / min for 60min at 45°C, filter Wash with deionized water until the lotion is neutral, and dry to obtain acid-modified Populus euphratica powder;

[0065] 3) Take 40-mesh Populus euphratica branch powder and heat it up to 350°C at 5°C / min in a muffle furnace to carbonize it for 2 hours to obtain Populus euphratica biochar; wash with 15% hydrochloric acid and deionized water, then dry, and place in a volume rati...

Embodiment 2

[0068] Embodiment 2: a kind of composite microbial bacterial agent:

[0069] 1) Prepared with 1.5×10 9 cfu / mL Bacillus amyloliquefaciens, 1.5×10 9 cfu / mL Pseudomonas azogenes, 1.4×10 9 cfu / mL Pseudomonas flavum, 1.5×10 9 cfu / mL Pseudomonas brucelli, 1.5×10 9 cfu / mL Pseudomonas rugosa, 1.4×10 9 cfu / mL yeast and 1.5×10 9 cfu / mL actinomycetes bacterial liquid;

[0070] 2) Take 100g of 60-mesh dry leaf powder of Populus euphratica, put it in 2000mL aqueous solution containing 1.5% α-butanuonic acid and 1.0‰4-sulfonic acid calixarene, stir and disperse at 300r / min for 30min at a temperature of 50°C, filter Wash with deionized water until the lotion is neutral, and dry to obtain acid-modified Populus euphratica powder;

[0071] 3) Take 40 mesh Populus euphratica branches and carbonize them in a muffle furnace at 10°C / min to 500°C for 1.5h to obtain Populus euphratica biochar; the Populus euphratica biochar is washed with 15% hydrochloric acid and deionized water, dried, and...

Embodiment 3

[0074] Embodiment 3: a kind of composite microbial bacterial agent:

[0075] 1) Prepared with 1.5×10 9 cfu / mL Bacillus amyloliquefaciens, 1.6×10 9 cfu / mL Pseudomonas azogenes, 1.6×10 9 cfu / mL Pseudomonas flavum, 1.3×10 9 cfu / mL Pseudomonas brucelli, 1.5×10 9 cfu / mL Pseudomonas rugosa, 1.3×10 9 cfu / mL yeast and 1.2×10 9 cfu / mL actinomycetes bacterial liquid;

[0076] 2) Take 50g of 60-mesh Populus euphratica dry branch powder and 50g of 60-mesh Populus euphratica dry leaf powder, place in 2L of aqueous solution containing 1.2% α-butanuonic acid and 1.0‰4-sulfonic acid calixarene, at a temperature of 48°C, at 240r / min Stir to disperse and modify for 45 minutes, filter out, wash with deionized water until the washing liquid is neutral, and dry to obtain acid-modified Populus euphratica powder;

[0077] 3) Take 40 meshes of Populus euphratica branches and leaves (weight ratio 2:1) and carbonize them in a muffle furnace at 8°C / min to 440°C for 2h to obtain Populus euphratica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com