Tantalum coating orthopedic implant material, preparation method thereof and orthopedic implant

A technology for orthopedic implants and implant materials, applied in the field of orthopedic implants, can solve the problem of difficult ingrowth of bone tissue, and achieve the effects of accelerating osseointegration, good application prospects and less potential harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

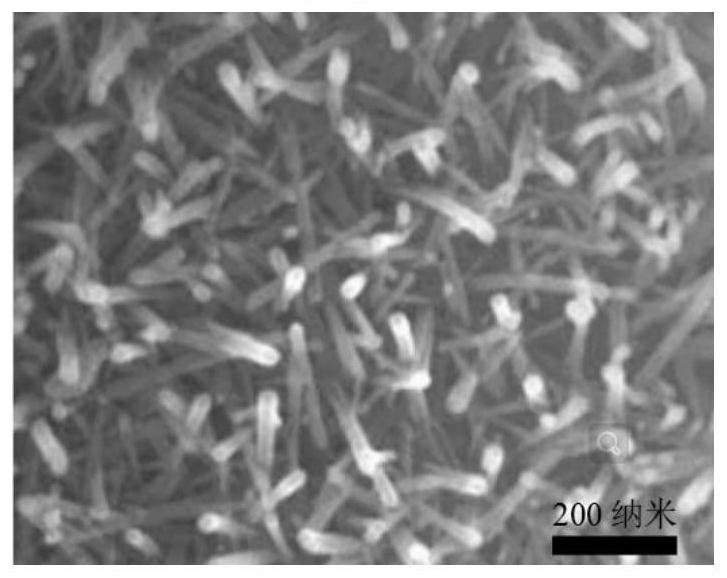

[0044] In order to further improve the preparation efficiency of the above-mentioned transition layer, tantalum coating and tantalum surface functional layer, the above-mentioned preparation method preferably includes: step S1, spraying titanium powder or titanium alloy particles on the base layer to form a transition layer; step S2, using laser In the cladding method, tantalum particles are sprayed on the transition layer to form a tantalum coating; in step S3, the tantalum coating is subjected to a hydrothermal reaction with a calcium salt and a strong alkali solution to obtain a tantalum-coated orthopedic implant material.

[0045] In order to improve the efficiency of the hydrothermal reaction of the above-mentioned step S3 of the present application, the process of the above-mentioned hydrothermal reaction preferably includes: immersing the material obtained in step S2 in the sodium hydroxide solution of 0.2mol / L calcium dihydrogen phosphate and 5mol / L In the process, the ...

Embodiment 1

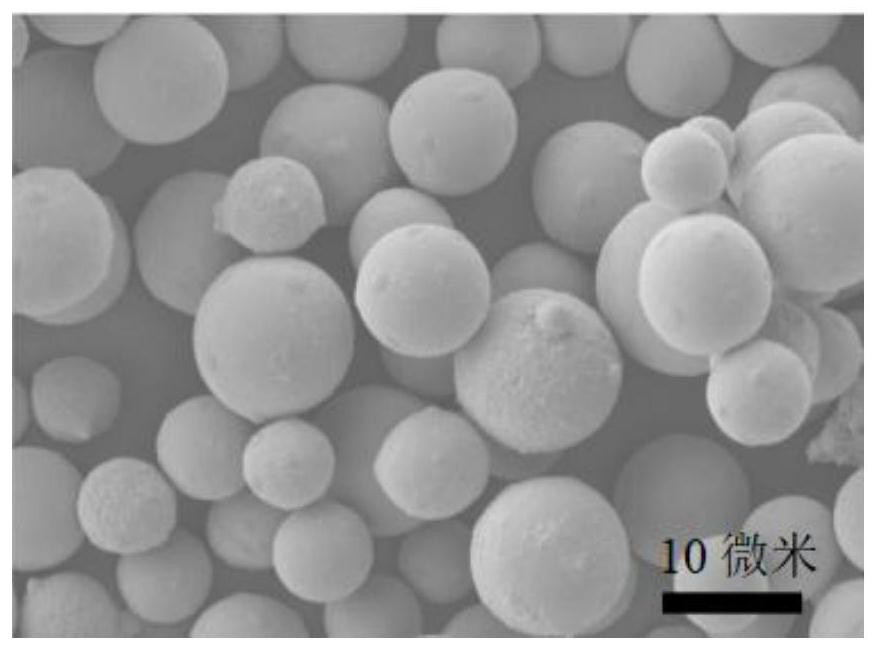

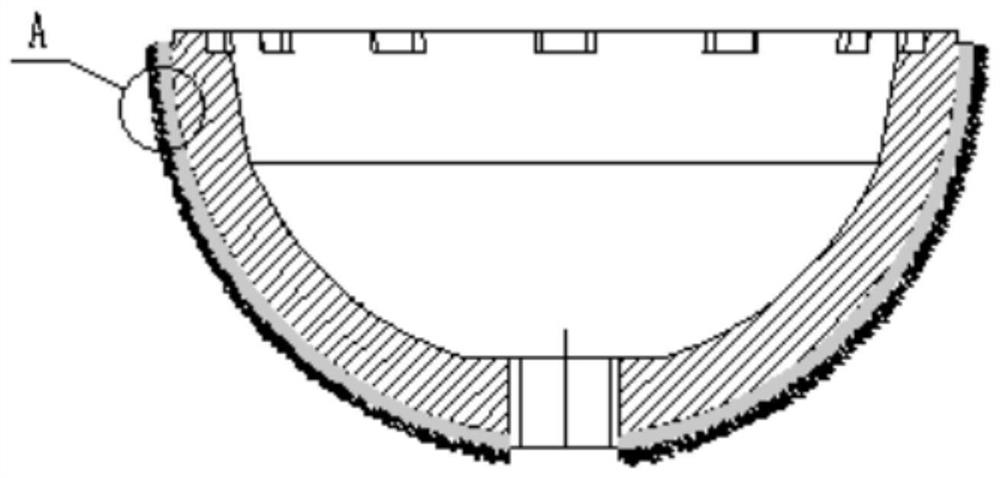

[0054] Tantalum-coated Ti-6Al-4V acetabular cups have an effective spherical outer diameter of 52 mm and acetabular height of 44 mm.

[0055] Surface pretreatment of the outer surface of the acetabular cup: the outer surface of the acetabular cup was polished with 200-grit sandpaper and 800-grit sandpaper for 3 minutes, and then polished with 1200-grit sandpaper for 5 minutes; and ultrasonically cleaned in acetone solution for 6 minutes; Ultrasonic cleaning with water for 5 minutes, and then drying to obtain the polished base layer; use aluminum oxide particles to perform sandblasting on the ground acetabular cup base layer to obtain the sandblasted acetabular cup base layer; the sandblasted acetabular base layer The base layer of the cup is subjected to acid etching treatment, the average particle size of alumina particles is 400 μm, the pressure of sand blasting treatment is 1 MPa, and the time of sand blasting treatment is 60 s; V(H 2 O): The mixed acid of V (sulfuric acid)...

Embodiment 2

[0060] The difference between embodiment 2 and embodiment 1 is that

[0061] The sphericity of the tantalum particles was 0.6, resulting in an orthopedic implant for the acetabular cup.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| D50 | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com