Preparation method of dipropylene glycol and catalyst thereof

A dipropylene glycol reduction and catalyst technology, which is applied in the direction of physical/chemical process catalysts, ether preparation, organic compounds/hydrides/coordination complex catalysts, etc., can solve problems such as corrosion equipment, polluted environment treatment, difficulties, etc., and achieve easy Recycling, high catalytic activity, mild effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

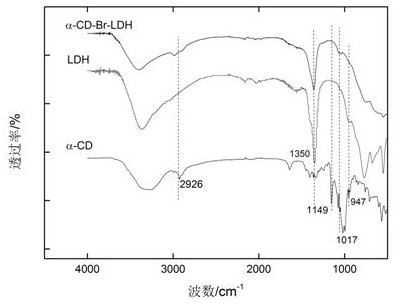

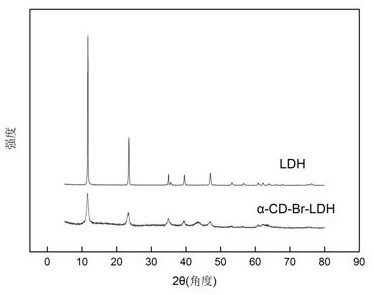

[0031] Specific Preparation of Heterogeneous Catalysts

[0032] (1) Preparation of Al-Mg hydrotalcite

[0033] The preparation method of the aluminum-magnesium hydrotalcite is as follows: the precursor aluminum-magnesium hydrotalcite with good crystallinity is synthesized by a hydrothermal uniform precipitation (urea hydrolysis) method. The experimental procedure is: take 12.82g of Mg(NO 3 ) 2 •6H 2 O, 9.38g of Al(NO 3 ) 3 •9H 2 O and 7.36g of urea are made into a mixed solution, wherein Mg 2+ : 0.1mol / L, Al 3+ : 0.05mol / L, urea: 0.245mol / L. Then take 50mL of the mixed solution and add it to a 100mL hydrothermal reaction kettle, and react at 140°C for 24 hours to obtain a white precipitate, which is washed with a large amount of distilled water, filtered with suction, and the obtained aluminum-magnesium hydrotalcite sample is dried in the air.

[0034](2) Preparation of nucleophilic ion and cyclodextrin compound

[0035] Calcining the aluminum-magnesium hydrotalcite ...

Embodiment 2

[0037] Specific Preparation of Heterogeneous Catalysts

[0038] (1) Preparation of Al-Mg hydrotalcite

[0039] This part of technical feature is identical with embodiment 1.

[0040] (2) Preparation of nucleophilic ion and cyclodextrin compound

[0041] Al-Mg hydrotalcite was calcined at 600°C for 3 hours to obtain Al-Mg oxide. The bromide ion is inserted into the hydrotalcite by utilizing the property of hydrotalcite calcining reduction. At the same time, cyclodextrin and hydrotalcite are combined to obtain a new type of composite material. The experimental steps are: use 0.973g of α-cyclodextrin to dissolve into 50 ml of carbon dioxide-free distilled water and add 0.2g of KBr, and add 0.2g of Al-MgO, and stirred at 60° C. for 24 hours under nitrogen protection. Suction filtration at room temperature and washing with a large amount of carbon dioxide-free distilled water to obtain a white solid, which was vacuum-dried at 80° C. for 10 h. The obtained heterogeneous catalys...

Embodiment 3

[0043] Specific Preparation of Heterogeneous Catalysts

[0044] This part of technical feature is identical with embodiment 1.

[0045] (2) Preparation of nucleophilic ion and cyclodextrin compound

[0046] A certain amount of aluminum-magnesium hydrotalcite is calcined at 400° C. for 4 hours to obtain aluminum-magnesium oxide. The bromide ion is inserted into the hydrotalcite by utilizing the property of hydrotalcite calcining reduction. At the same time, cyclodextrin and hydrotalcite are combined to obtain a new type of composite material. The experimental steps are: use 1.134g of β-cyclodextrin to dissolve into 50 ml of carbon dioxide-free distilled water and add 0.2g of KBr, and add 0.2g of Al-Mg oxide, and stirred at 2.0 Mpa at 80° C. for 24 hours under a nitrogen protection environment. Suction filtration at room temperature and washing with a large amount of carbon dioxide-free distilled water to obtain a white solid, which was vacuum-dried at 60° C. for 12 h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com