Production method of o-toluic acid or m-toluic acid

A technology of o-toluic acid and toluic acid, applied in chemical instruments and methods, separation/purification of carboxylic acid compounds, preparation of carboxylate, etc., can solve the problem of increased waste, poor economy, and low conversion rate and other issues, to achieve the effect of huge economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

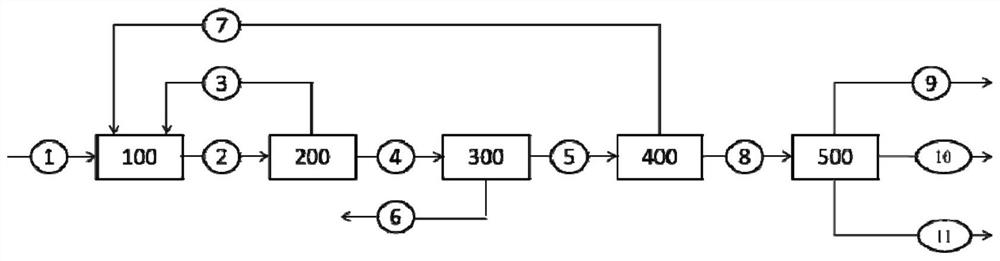

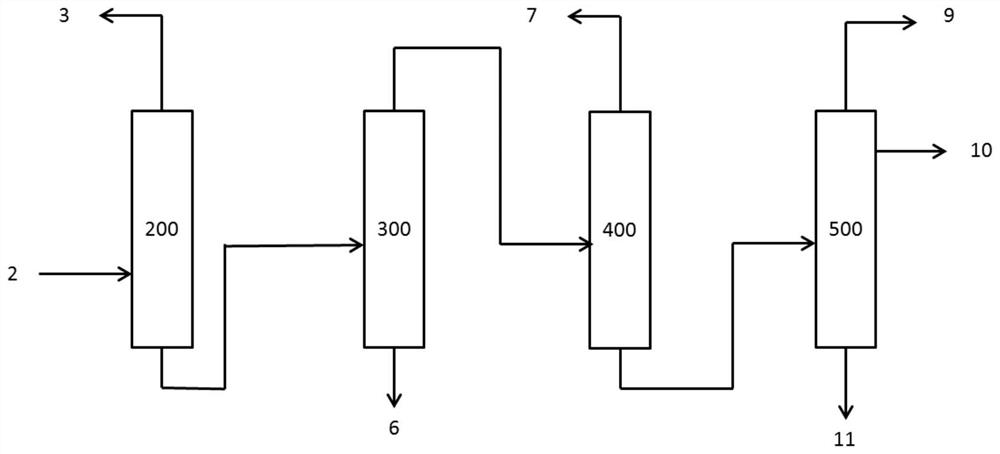

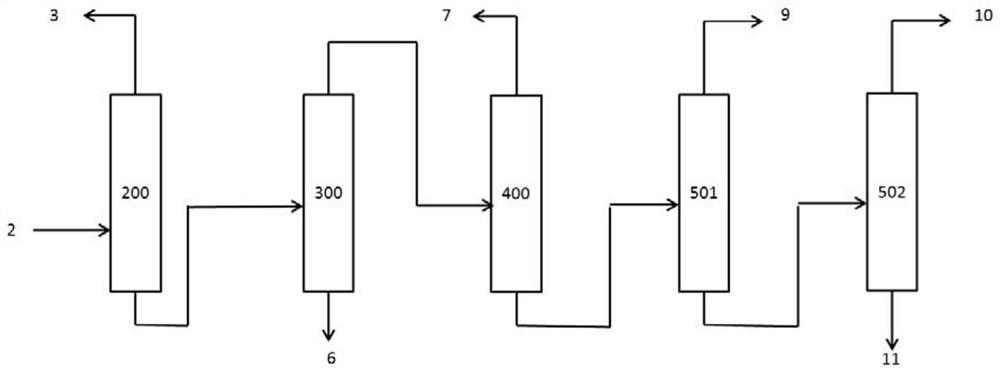

[0122] In the present invention, the preparation method of described methylbenzoic acid comprises:

[0123] Carrying out the oxidation reaction of xylene to form an oxidation reaction liquid;

[0124] Carrying out a delightening operation on the oxidation reaction liquid, separating light components including xylene to form a delightening mother liquor;

[0125] Carrying out de-heavy operation on the de-light mother liquor, separating heavy components comprising phthalic acid and carboxybenzaldehyde to form de-heavy light components;

[0126] Carrying out rectification to the deheavy light components, separating the intermediate components comprising methyl benzyl alcohol and methyl benzaldehyde, forming rectification mother liquor; and

[0127] The rectification mother liquor is refined, and the benzoic acid and the refined raffinate are separated to obtain the target product toluic acid.

[0128] In an embodiment of the present invention, the delightening operation is carr...

Embodiment 1

[0201] The m-xylene was transported to the bubble column by a transfer pump, and oxidized with air under the conditions of 168° C. and 0.63 MPa to obtain an oxidation reaction liquid of m-xylene. The oxidation reaction solution was tested, and its composition is shown in Table 1 below.

[0202] Table 1:

[0203]

[0204]The above-mentioned oxidation reaction liquid is transported to the light removal equipment through a transport pump, and after being preheated by a preheater, it enters a rectification tower for vacuum distillation. Under the conditions of a pressure of 30kPa and a temperature of the tower bottom of 148.5°C, the m-xylene in the oxidation reaction liquid is vaporized and enriched to the top of the tower, and then condensed by a condenser and collected in a light component collection tank for temporary storage, and then passed through The transfer pump transfers to the bubble column of the oxidation equipment. The light-removing mother liquor containing m-m...

Embodiment 2

[0207] The o-xylene is transported to the bubble column by a transfer pump, and oxidized with air under the conditions of 145° C. and 0.45 MPa to obtain an oxidation reaction liquid of o-xylene. The oxidation reaction solution was tested, and its composition is shown in Table 2 below.

[0208] Table 2:

[0209]

[0210] The above-mentioned oxidation reaction liquid is transported to the light removal equipment through the delivery pump, and after being preheated by the preheater, it enters the flash tank for negative pressure flash evaporation, and the o-xylene in the oxidation reaction liquid is rapidly vaporized under the conditions of 30kPa and 125°C The light component whose main component is o-xylene is extracted from the steam outlet, which is directly transported to the bubble column of the oxidation equipment through pipelines, and the o-tolualdehyde, o-methylbenzyl alcohol, and o-toluene are extracted at the liquid outlet. The light-removing mother liquor whose bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com