Preparation method and application of ZnO nanowire sensitive material

A technology of sensitive materials and nanowires, which is applied in the field of preparation of sensitive materials to achieve the effects of not easy to agglomerate, good surface permeability and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Preparation of ZnO nanomaterials

[0033] Step 1: Use a silicon substrate with a thin layer of silicon oxide on its surface as a substrate, put it in acetone, ethanol, and deionized water for ultrasonic cleaning, and then blow dry.

[0034] Step 2: Weigh 300 mg of high-purity zinc powder, grind it fully with a grinding pot, and place it in the central area of the alumina porcelain boat.

[0035] Step 3: Put the silicon substrate cleaned in step 1 on the alumina porcelain boat in step 1, at a position directly above the Zn source, and then put the porcelain boat into the high-temperature area of the tubular reaction furnace.

[0036] Step 4: Introduce nitrogen as a carrier gas, and the flow rate of nitrogen is 150 mL / min. After 10 minutes, the furnace tube temperature was raised to 750°C at a ramp rate of 10°C / min and maintained at this temperature for 1 hour. Then naturally cooled to room temperature.

[0037] Step 5: Take out the silicon substrate, and find ...

Embodiment 2

[0041] (1) Preparation of ZnO nanomaterials

[0042] Step 4: Introduce nitrogen as a carrier gas, and the flow rate of nitrogen is 150 mL / min. After 10 minutes, the furnace tube temperature was raised to 800°C at a rate of 10°C / min and maintained at this temperature for 1 hour. Then naturally cooled to room temperature.

[0043] Steps 1, 2, 3 and 5 are the same as in Example 1.

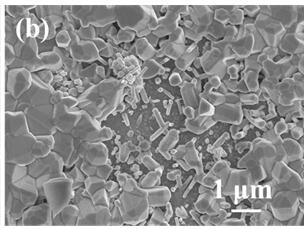

[0044] (2) Morphological characterization of ZnO nanomaterials

[0045] The morphology of the product was characterized by scanning electron microscopy. As shown in Figure 1(b), the ZnO product is composed of irregular particles with a particle size of about 50-1000 nm. Compared with Example 1, the particle size is increased, and a thin rod-shaped product appears.

Embodiment 3

[0047] (1) Preparation of ZnO nanomaterials

[0048] Step 4: Introduce nitrogen as a carrier gas, and the flow rate of nitrogen is 150 mL / min. After 10 minutes, the furnace tube temperature was raised to 850°C at a rate of 10°C / min and maintained at this temperature for 1 hour. Then naturally cooled to room temperature.

[0049] Steps 1, 2, 3 and 5 are the same as in Example 1.

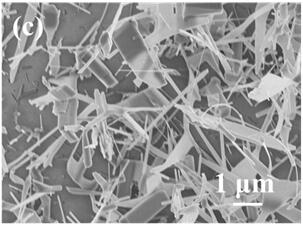

[0050] (2) Morphological characterization of ZnO nanomaterials

[0051] The morphology of the product was characterized by scanning electron microscopy. As shown in Figure 1(c), the ZnO product is composed of irregular nanosheets, nanorods, and nanowires, and the particle size is significantly smaller than that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com