Silicone rubber material with high corrosion resistance and preparation method thereof

A corrosion-resistant, silicone rubber technology, applied in the field of high corrosion-resistant silicone rubber materials and its preparation, can solve the problems of easy hydrolysis reaction, poor hydrolysis and corrosion resistance, and decreased mechanical properties of products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The present embodiment is a preparation method of modified silicone rubber, comprising the following steps:

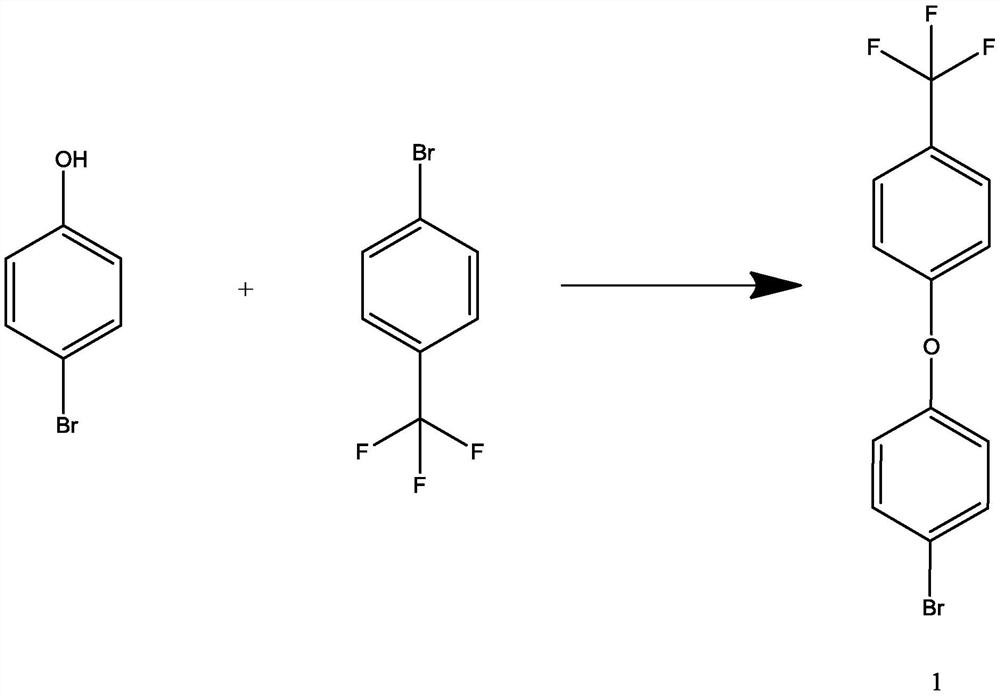

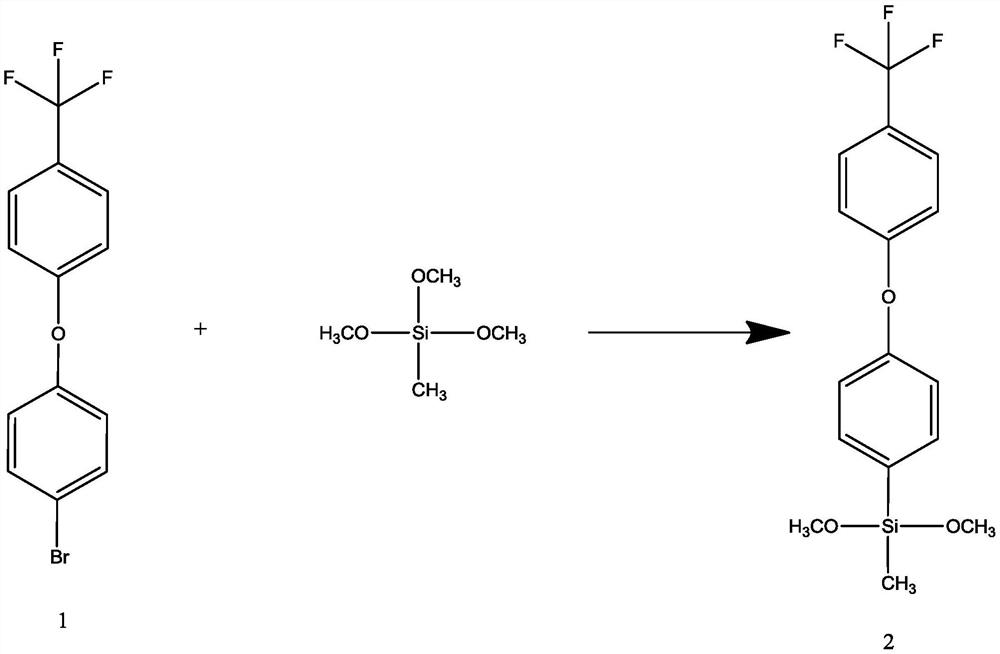

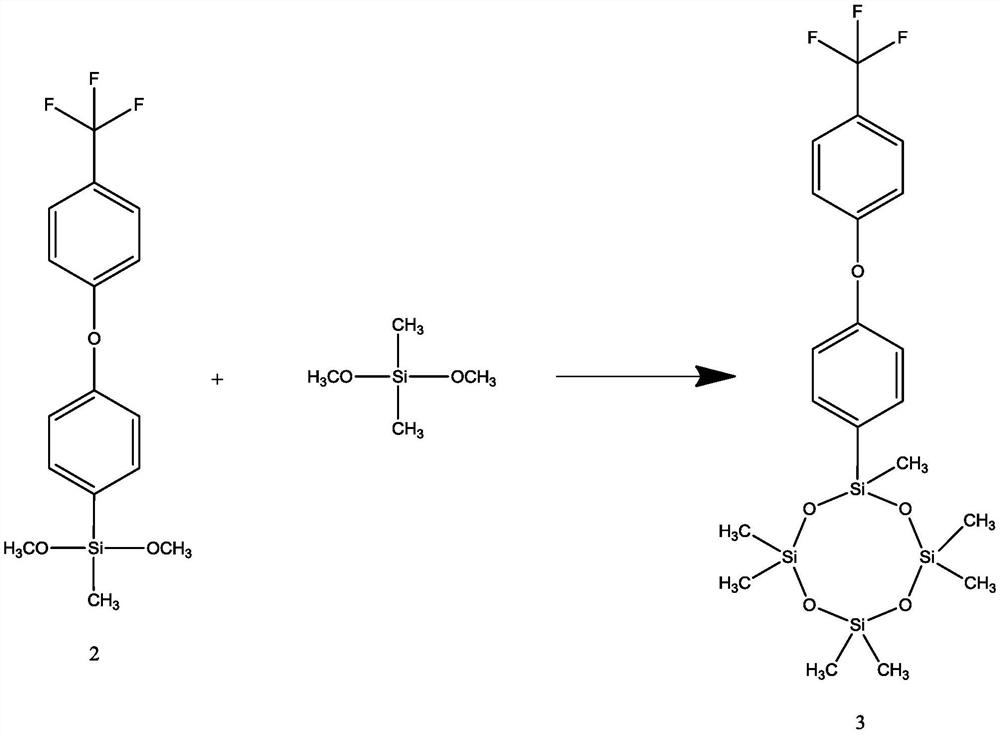

[0050] A1: P-bromophenol, cesium carbonate and dimethyl sulfoxide were added to a three-necked flask equipped with a stirrer, a gas pipe and a constant pressure dropping funnel, protected by argon, and the stirring rate was 500 r / min at room temperature Stir for 10 h under the same conditions, and then add p-bromotrifluorotoluene dropwise while stirring, and control the drop rate to be 5 mL / min. After the dropwise addition, the temperature is raised to 50 °C, and the stirring reaction is continued for 20 h, and the heating rate is controlled to 1 °C / min. After the reaction was completed, vacuum filtration, the filtrate was extracted twice with ethyl acetate, the extracts were combined and washed twice with saturated sodium chloride solution, left to stand for layers, the organic layer was dried with anhydrous sodium sulfate, and then the organic layer was After ...

Embodiment 2

[0055] The present embodiment is a preparation method of modified silicone rubber, comprising the following steps:

[0056] A1: P-bromophenol, cesium carbonate and dimethyl sulfoxide were added to a three-necked flask equipped with a stirrer, a gas pipe and a constant pressure dropping funnel, protected by argon gas, and the stirring rate was 800 r / min at room temperature Stir for 12h under the same conditions, then add p-bromotrifluorotoluene dropwise while stirring, control the dropwise acceleration rate to 1mL / min, after the dropwise addition, the temperature is raised to 55°C and continue to stir for 30h, and the heating rate is controlled to 1°C / min, After the reaction was completed, vacuum filtration, the filtrate was extracted three times with ethyl acetate, the extracts were combined and washed three times with saturated sodium chloride solution, left to stand for layers, the organic layer was dried with anhydrous sodium sulfate, and then the organic layer was After co...

Embodiment 3

[0061] The present embodiment is a preparation method of a hydrolysis inhibitor, comprising the following steps:

[0062] Add bisphenol A, epichlorohydrin, deionized water, and isopropanol into a four-necked flask equipped with a stirrer, a reflux condenser and a constant-pressure dropping funnel, and stir at a stirring rate of 500 r / min. When the bisphenol A is completely dissolved, the sodium hydroxide solution is added dropwise while stirring under the condition of heating up to 70 °C, and the drop rate is controlled to be 2 seconds / drop. Then add chloroform to the reaction product and continue to stir for 5 min, then wash with distilled water for 3 times, let stand for layers, collect the organic phase and dry with anhydrous magnesium sulfate, filter, and rotate the filtrate to evaporate, and then pass the evaporated product through a silica gel column layer. Purified by analytical method, then placed in a vacuum drying oven to dry to obtain a hydrolysis inhibitor; the dos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com