Anticorrosive bactericidal coating and preparation method thereof

A technology of bactericidal coatings and raw materials, applied in anti-corrosion coatings, anti-fouling/underwater coatings, epoxy resin coatings, etc., can solve the problems of poor anti-corrosion and sterilization performance, achieve long anti-corrosion time, low production cost, smooth and beautiful surface Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

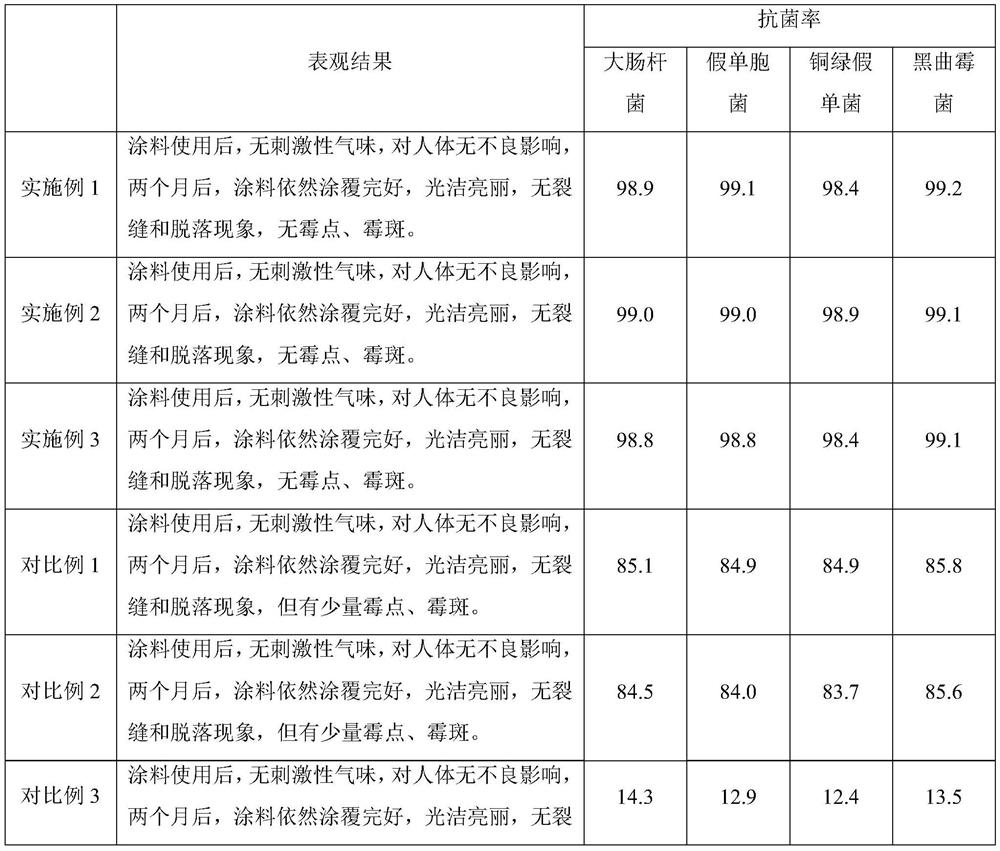

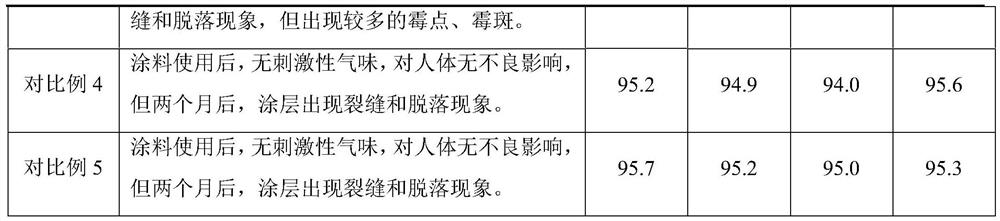

Examples

Embodiment 1

[0044]A kind of antiseptic and bactericidal paint, comprises the raw material of following mass parts:

[0045] 55 parts of bisphenol A epoxy resin, 15 parts of silane coupling agent KH550, 10 parts of fluorosilicon modified resin, 8 parts of dodecyl alcohol ester, 15 parts of talcum powder, 3 parts of paraffin wax, 4 parts of antibacterial additive and ethylene glycol 5 parts of dimethyl ether;

[0046] 1. The antibacterial additive is prepared through the following steps:

[0047] S1: Dried the dregs of the decocted antibacterial traditional Chinese medicine until the water content is less than 5%, then crushed into a powder with a particle size of about 50 mesh, and then heat-treated the obtained powder under the protection of nitrogen to obtain an antibacterial precursor; heat treatment temperature The temperature is 250°C, and the treatment time is 2 hours; the antibacterial traditional Chinese medicine includes the following components by mass:

[0048] 12 parts of dan...

Embodiment 2

[0062] A kind of antiseptic and bactericidal paint, comprises the raw material of following mass parts:

[0063] 60 parts of bisphenol A epoxy resin, 10 parts of silane coupling agent KH570, 12 parts of fluorosilicon modified resin, 5 parts of dodecyl alcohol ester, 20 parts of mica powder, 2 parts of sodium dodecylbenzenesulfonate, antibacterial 5 parts of additives and 2 parts of ethylene glycol dimethyl ether;

[0064] 1. The antibacterial additive is prepared through the following steps:

[0065] S1: Dried the dregs of the decocted antibacterial traditional Chinese medicine until the water content is less than 5%, then crushed into a powder with a particle size of about 40 mesh, and then heat-treated the obtained powder under the protection of nitrogen to obtain an antibacterial precursor; heat treatment temperature The temperature is 300°C, and the treatment time is 1h; the antibacterial traditional Chinese medicine includes the following components by mass:

[0066] 10...

Embodiment 3

[0080] A kind of antiseptic and bactericidal paint, comprises the raw material of following mass parts:

[0081] 50 parts of bisphenol A epoxy resin, 20 parts of silane coupling agent KH550, 8 parts of fluorosilicon modified resin, 10 parts of dodecyl alcohol ester, 10 parts of mica powder, 10 parts of talcum powder, dodecylbenzenesulfonic acid 4 parts of sodium, 2 parts of antibacterial additive and 5 parts of ethylene glycol dimethylol ether;

[0082] The antibacterial additive is made through the following steps:

[0083] S1: Dried the dregs of the decocted antibacterial traditional Chinese medicine until the water content is less than 5%, then crushed into a powder with a particle size of about 50 mesh, and then heat-treated the obtained powder under the protection of nitrogen to obtain an antibacterial precursor; heat treatment temperature The temperature is 280°C, and the treatment time is 2 hours; the antibacterial traditional Chinese medicine includes the following co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com