Controllable preparation and modification method of nickel ferrite nanoparticles

A nanoparticle, nickel ferrite technology, applied in the field of materials, can solve the problems of difficult storage, easy agglomeration and sedimentation of nanoparticles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

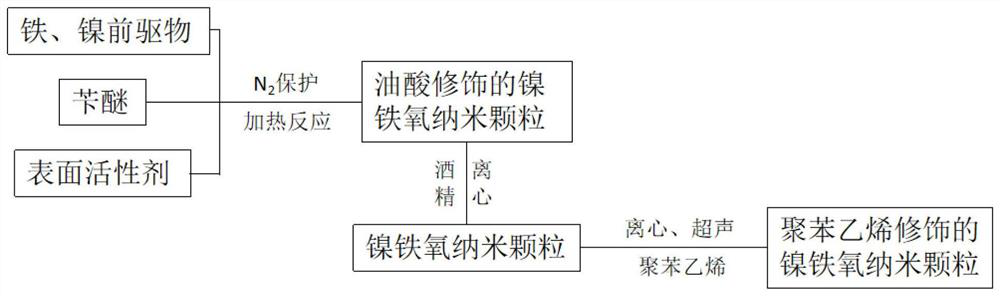

Method used

Image

Examples

Embodiment 1

[0036] 1) Add 0.78g iron (III) acetylacetonate, 0.56g nickel (II) acetylacetonate, 0.9g sodium oleate, 6ml oleic acid, and 30mL benzyl ether solution into a 100mL three-necked reaction flask, stir to dissolve, and N 2 Under protection, the temperature was raised to 295° C. at a rate of 6° C. / min, and reacted for 1 hour to produce black nickel ferrite particle crystals with a mass of about 0.42 g.

[0037] 2) Take the above reaction product, use centrifugation, add an appropriate amount of n-hexane to wash, and then use centrifugation to repeat five times to obtain nickel ferrite nanoparticles coated with oleic acid.

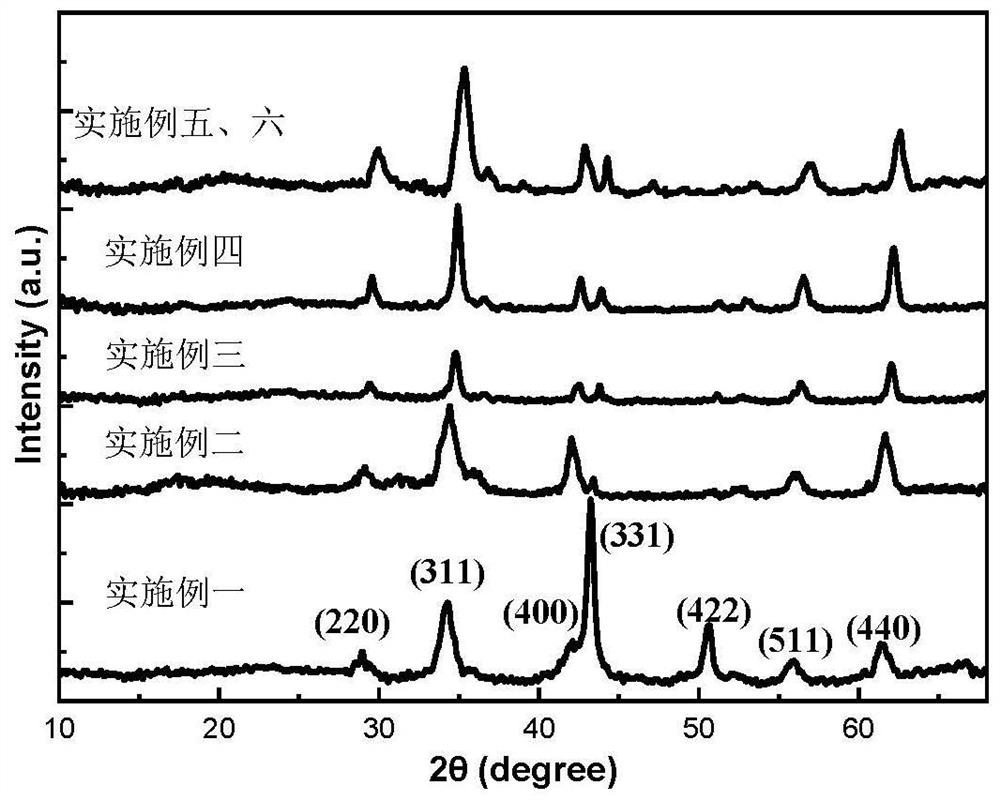

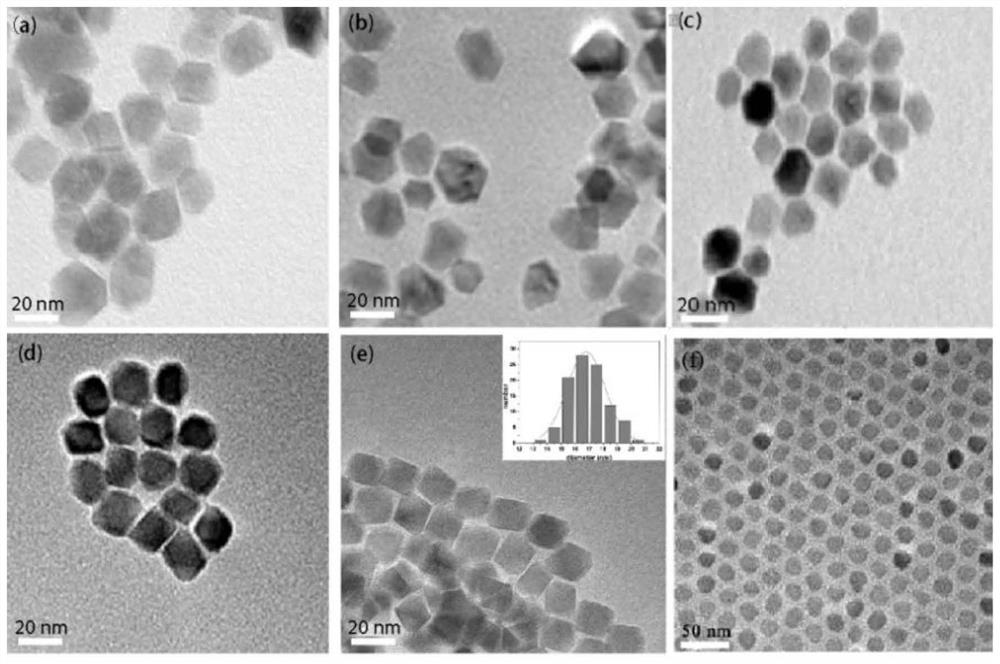

[0038] Such as figure 2 As shown, the X-ray diffraction pattern shows that the black solid prepared in the present embodiment is nickel ferrite nanoparticles; the transmission electron microscope image of preparing nanoparticles is as follows image 3 As shown in (a), it can be seen from the figure that the size distribution of the nanoparticles is relatively ...

Embodiment 2

[0042] 1) Add 1.162g iron (III) acetylacetonate, 0.283g nickel (II) acetylacetonate, 0.9g sodium oleate, 6ml oleic acid, and 30mL benzyl ether solution into a 100mL three-necked reaction flask, stir to dissolve, and N 2Under protection, the temperature was raised to 295° C. at a rate of 6° C. / min, and reacted for 1 hour to produce black nickel ferrite particle crystals with a mass of about 0.42 g.

[0043] 2) Take 1 mL of oleic acid-coated nickel ferrite nanoparticles (about 10 mg), use centrifugation, add an appropriate amount of n-hexane to wash, and use centrifugation to repeat five times.

[0044] Such as figure 2 As shown, the X-ray diffraction pattern shows that the black solid prepared in the present embodiment is nickel ferrite nanoparticles; the transmission electron microscope image of preparing nanoparticles is as follows image 3 As shown in (b), it can be seen from the figure that the size distribution of the nanoparticles is relatively uniform, and the diamete...

Embodiment 3

[0048] 1) Add 1.27g iron (III) acetylacetonate, 0.19g nickel (II) acetylacetonate, 0.9g sodium oleate, 6ml oleic acid, and 30mL benzyl ether solution into a 100mL three-necked reaction flask, stir to dissolve, and N 2 Under protection, the temperature was raised to 295° C. at a rate of 6° C. / min, and reacted for 1 hour to produce black nickel ferrite particle crystals with a mass of about 0.42 g.

[0049] 2) Take 1 mL of oleic acid-coated nickel ferrite nanoparticles (about 10 mg), use centrifugation, add an appropriate amount of n-hexane to wash, and use centrifugation to repeat five times.

[0050] Such as figure 2 As shown, the X-ray diffraction pattern shows that the black solid prepared in this embodiment is nickel ferrite nanoparticles; the transmission electron microscope image of the magnetic nickel ferrite nanoparticles body prepared is as follows image 3 As shown in (c), it can be seen from the figure that the size distribution of the nanoparticles is relatively ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com