Alpha, alpha-dideuterated benzyl alcohol compound, deuterated medicine and reduction deuteration method of benzoate compound

A technology of ester compounds and benzoic acid, which is applied in the field of reductive deuteration of new benzoic acid ester compounds, can solve the problems of poor site selectivity of deuterated reaction, expensive metal deuterated compounds, and low deuterated rate of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

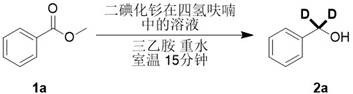

Embodiment 1

[0044]

[0045] Into a 50 mL single-necked round bottom flask under the protection of argon, add samarium diiodide (SmI 2 ) in tetrahydrofuran (0.1 mol / L) 12 mL, compound 1a 27.2 mg (0.200 mmol), triethylamine 0.33 mL (2.4 mmol) and heavy water 0.260 mL (14.4 mmol). The reaction mixture was stirred at room temperature for 15 min before being quenched with air. Dichloromethane and saturated sodium hydroxide solution were added for extraction, the organic phase was dried, concentrated, and separated by column chromatography to obtain 11.9 mg of the target compound 2a with a yield of 54% and a deuteration rate of 97%.

[0046] The target product 2a obtained by the above synthesis method was detected by proton nuclear magnetic resonance spectrum and carbon spectrum, and the test results were as follows: 1 H NMR (300 MHz, CDCl 3 ) δ 7.39 – 7.23 (m, 5H), 2.02 (br, 1H); 13 C{ 1 H) NMR (75 MHz, CDCl 3 ) δ 140.8, 128.6, 127.7, 127.1, 64.7 (m).

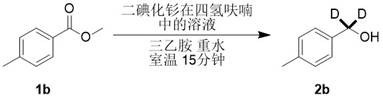

Embodiment 2

[0048]

[0049] Into a 50 mL single-necked round bottom flask under the protection of argon, add samarium diiodide (SmI 2 ) in tetrahydrofuran (0.1 mol / L) 12 mL, compound 1b 30.0 mg (0.200 mmol), triethylamine 0.33 mL (2.4 mmol) and heavy water 0.260 mL (14.4 mmol). The reaction mixture was stirred at room temperature for 15 min before being quenched with air. Dichloromethane and saturated sodium hydroxide solution were added for extraction, the organic phase was dried, concentrated, and separated by column chromatography to obtain 20.4 mg of the target compound 2b, with a yield of 82% and a deuteration rate of 98%.

[0050] The target product 2b obtained by the above synthesis method was detected by proton nuclear magnetic resonance spectrum and carbon spectrum, and the test results are as follows: 1 H NMR (300 MHz, CDCl 3 ) δ 7.24 (m, 2H), 7.16 (m, 2H), 2.34 (s, 3H), 1.74(br, 1H); 13 C{ 1 H) NMR (75 MHz, CDCl 3 ) δ 137.9, 137.5, 129.3, 127.2, 64.6 (m), 21.2.

Embodiment 3

[0052]

[0053] Into a 50 mL single-necked round bottom flask under the protection of argon, add samarium diiodide (SmI 2 ) in tetrahydrofuran (0.1 mol / L) 12 mL, compound 1c 30.0 mg (0.200 mmol), triethylamine 0.33 mL (2.4 mmol) and heavy water 0.260 mL (14.4 mmol). The reaction mixture was stirred at room temperature for 15 min before being quenched with air. Dichloromethane and saturated sodium hydroxide solution were added for extraction, the organic phase was dried, concentrated, and separated by column chromatography to obtain 19.1 mg of the target compound 2c with a yield of 77% and a deuteration rate of 97%.

[0054] The target product 2c obtained by the above synthesis method was detected by proton nuclear magnetic resonance spectrum and carbon spectrum. The test results are as follows: 1H NMR (300 MHz, CDCl3) δ 7.33 (m, 1H), 7.24 – 7.15 (m, 3H), 2.35 (s,3H), 1.66 (br, 1H); 13C{1H} NMR (75 MHz, CDCl3) δ 138.7, 136.2, 130.4, 127.9, 127.7, 126.1, 62.9 (m), 18.7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com