Fatty alcohol polyoxypropylene ether oxyacid and salts thereof

A technology of alcohol polyoxypropylene ether and oxyacid, which is applied in the direction of sulfuric acid ester preparation, organic carbonate preparation, and compounds of Group 5/15 elements of the periodic table, etc., which can solve the problem of easy transfer of active centers and low molecular weight of polymers , wide molecular weight distribution and other issues, to achieve the effect of reducing the content of irritating and harmful substances, improving product quality and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] The present invention also provides a method for preparing the fatty alcohol polyoxypropylene ether oxyacid or its salt. The method uses propylene oxide as a raw material, fatty alcohol as an initiator, and reacts with an end-capping agent to obtain a narrow The fatty alcohol polyoxypropylene ether oxyacid or its salt of distribution specifically comprises the following steps:

[0056] Step 1, adding fatty alcohol into propylene oxide, heating and reacting to obtain an intermediate reaction liquid.

[0057] The fatty alcohol is selected from saturated monohydric alcohols, preferably selected from saturated straight chain monohydric alcohols or saturated branched chain monohydric alcohols, more preferably saturated monohydric alcohols with the following structure:

[0058]

[0059] Among them, R 1 and R 2 Defined as above: R 1 selected from a hydrogen atom or a linear alkyl group, preferably from a hydrogen atom or C 1 -C 10 A straight-chain alkyl group, more pre...

Embodiment 1

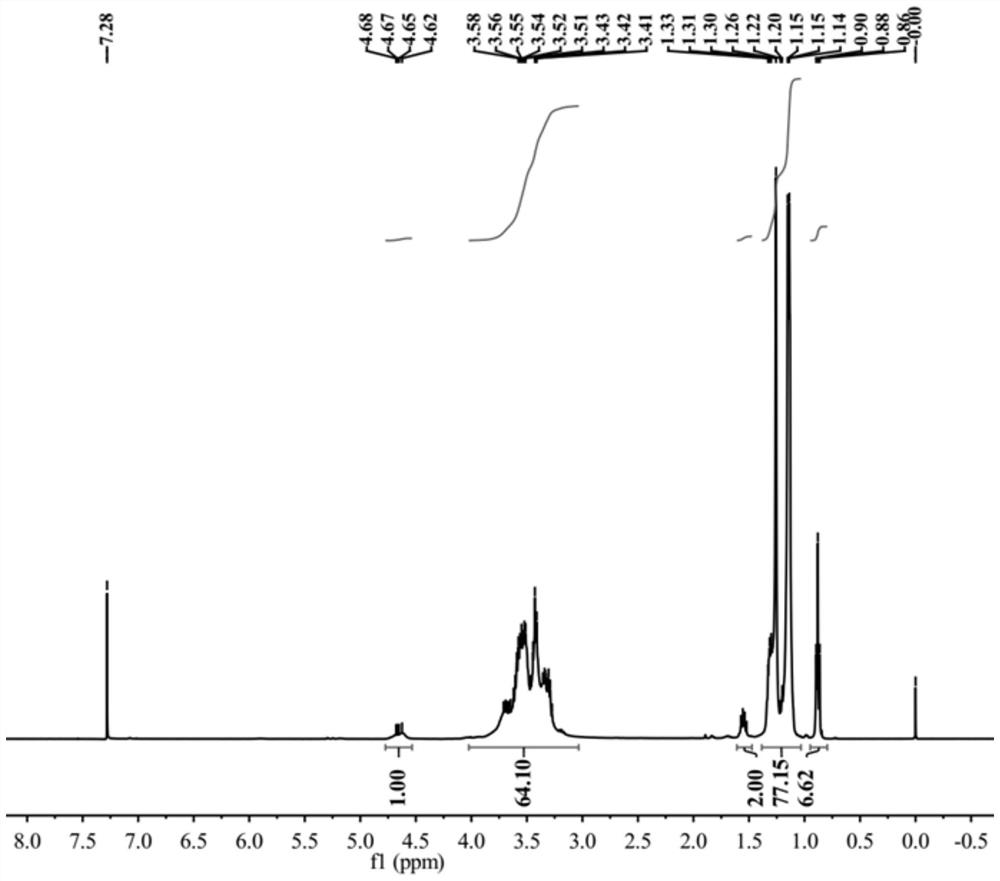

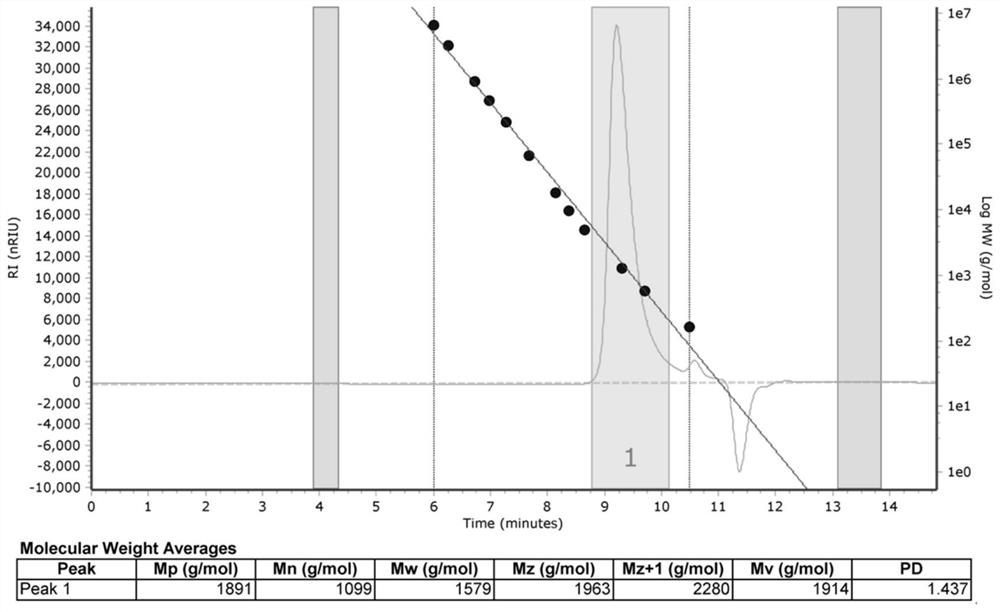

[0102] The addition of materials is carried out in the glove box, the MgI of 0.5mmol NHC1, 1mmol 2 , 1.25 mmol of 1-tetradecyl alcohol were sequentially added into a 10 mL Schlenk reaction tube. Move the reaction tube out of the glove box, add 10mmol propylene oxide by injection, heat to 60°C under stirring conditions, and start timing. 1 H NMR monitors the progress of the monomer polymerization reaction, and stops the reaction after 48 hours.

[0103] Add 3.125 mmol of sulfur trioxide-triethylamine complex into the Schlenk reaction tube, react for 12 h, add methanol to quench the reaction. After the methanol solvent and a small amount of residual monomers were removed by rotary evaporation, n-hexane was added, the polymer was separated by filtration, and dried to constant weight at room temperature under a vacuum of 0.1-0.001 mbar to obtain polyoxytetradecyl alcohol Propylene ether sulfuric acid has a structure as shown in formula (1) inferred, and the conversion rate of pr...

Embodiment 2

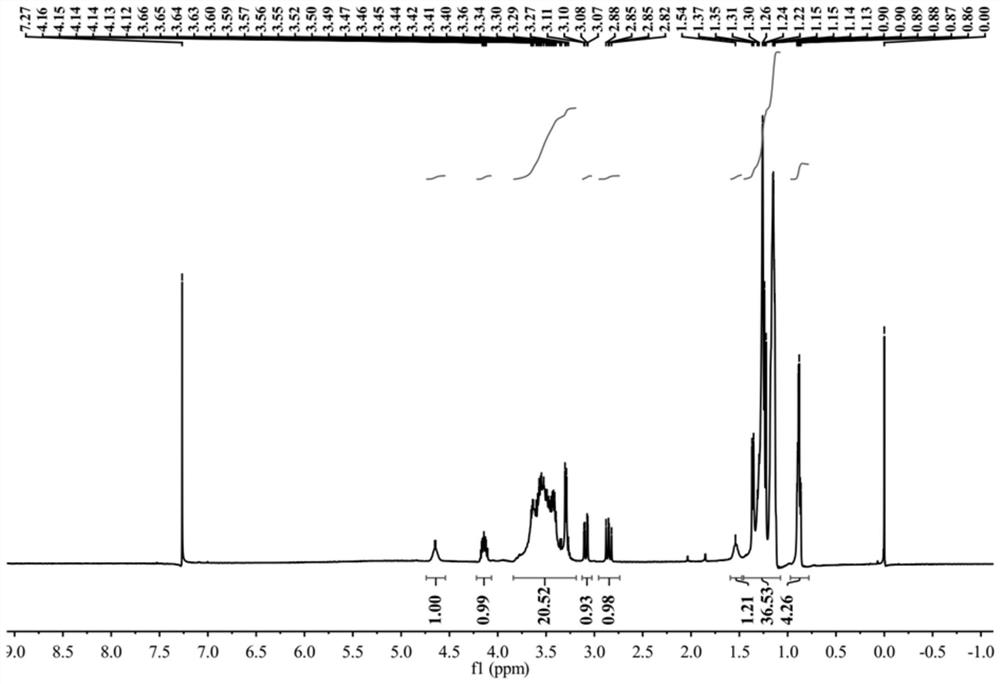

[0107] Synthesize 2-methyl-1-tridecanol polyoxypropylene ether sulfuric acid according to the method for embodiment 1, presumably its structure is as shown in formula (2). The only difference is that 1.25 mmol of 1-tetradecyl alcohol was replaced by 1.25 mmol of 2-methyl-1-tridecyl alcohol. The conversion of propylene oxide was 95%.

[0108] pass 1 H NMR test confirmed the structure of the product, 1 H NMR test spectrum as image 3 As shown, the degree of polymerization n is about 5.

[0109] The molecular weight of the product measured by gel permeation chromatography coupled with laser light scattering (GPC) is M n =720g·mmol -1 And the molecular weight distribution index was PDI=1.39.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com