Wear-resistant ultra-high performance concrete and preparation method thereof

An ultra-high-performance concrete technology, applied in the field of concrete, can solve problems such as low strength, expensive ceramic aggregates, and inability to further improve wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1 Preparation of high-iron high-belite sulphoaluminate cement clinker powder

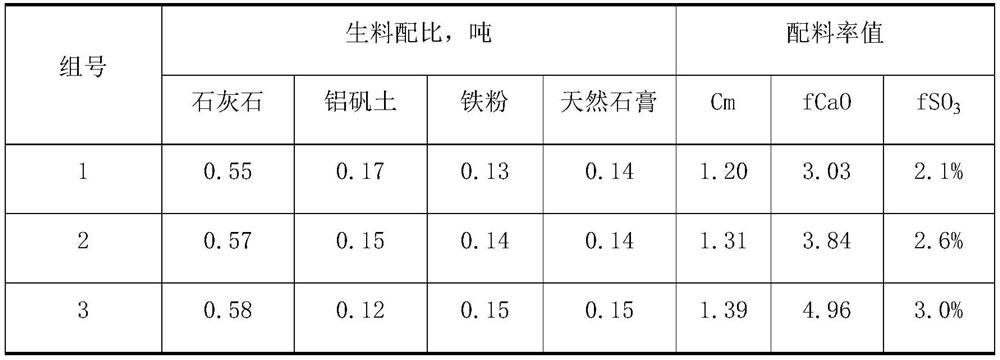

[0037] According to the raw meal weight ratio and batching rate value shown in Table 1, grinding to obtain 1.0 tons of raw meal with a fineness of 0.08mm and a sieve residue of less than 8%, after calcining at 1310°C in a rotary kiln, 0.74 tons (raw meal burned Loss of 26%) high iron high belite sulfoaluminate cement clinker, after grinding to obtain a specific surface area of 400 ~ 450m 2 / kg of high iron high belite sulphoaluminate cement clinker powder.

[0038] Table 1 Raw meal ratio and ingredient rate value

[0039]

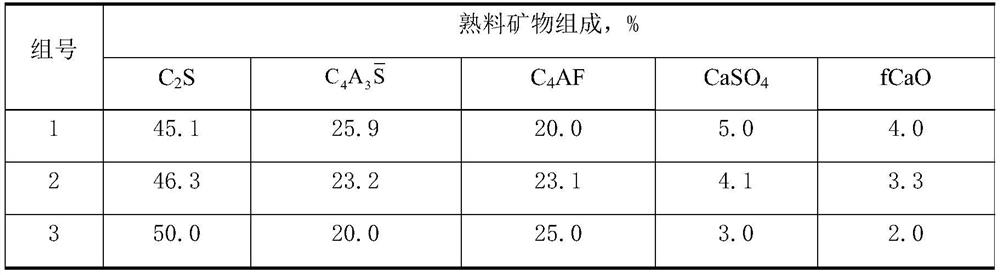

[0040] The mineral composition of high-iron high-belite sulfoaluminate cement clinker is shown in Table 2.

[0041] Table 2 Mineral composition of high-iron high-belite sulfoaluminate cement clinker

[0042]

[0043] According to the standard GB17671-1999 "Cement mortar strength test method (ISO method)", GB / T1346-2011 "Cement standard consistency wat...

Embodiment 2

[0048] The preparation of embodiment 2 special gelling materials

[0049] According to the weight ratio shown in Table 4, each component was added into the dry powder mixer in sequence, and the wear-resistant UHPC special gel material was obtained through thorough and uniform mixing.

[0050] The weight proportion of table 4 special cementitious material

[0051]

[0052] According to the standard GB17671-1999 "Cement Mortar Strength Test Method (ISO Method)", GB / T1346-2011 "Cement Standard Consistency Water Consumption, Setting Time, Stability Test Method", the physical properties of the above-mentioned groups of special cementitious materials The measurement was carried out according to JC / T421-2004 "Test Method for Abrasion Resistance of Cement Mortar", and the results are shown in Table 5.

[0053] Table 5 Physical properties of special cementitious materials

[0054]

[0055]

[0056] It can be seen from Table 5 that the special cementitious material composed o...

Embodiment 3

[0057] Embodiment 3 Preparation of wear-resistant UHPC material

[0058] In this embodiment, SiO in silica fume 2 The content is greater than 95%, and the specific surface area is not less than 20000m 2 / kg. Steel slag aggregate is the solid waste slag-steel slag produced in the metallurgical industry, which is crushed and screened to make its particle size ≥1.0mm and ≤3.0mm; iron tailings sand is the mineral processing tailings produced in iron ore beneficiation -Iron tailings, obtained by drying and sorting, so that the particle size is ≥0.5mm and ≤1.0mm; quartz sand is washed and dried sand with a particle size of ≤0.5mm; Water agent, the water reducing rate is greater than 30%; the length of the copper-plated steel fiber is 10mm-15mm, and the diameter is 0.15mm-0.2mm.

[0059] Group number 1:

[0060] Weigh each raw material component according to the following weight: 650g of special cementitious material; 150g of silica fume; 620g of steel slag aggregate; 350g of iro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com