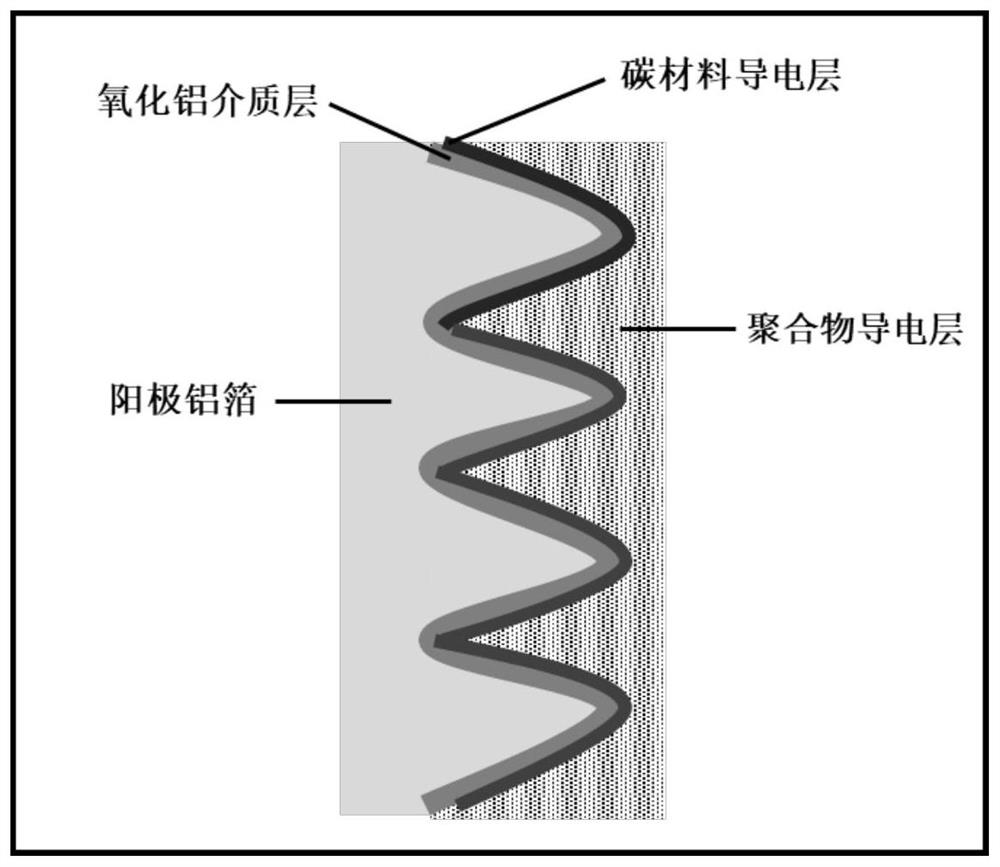

Method for preparing conductive polymer cathode in solid-state aluminum electrolytic capacitor

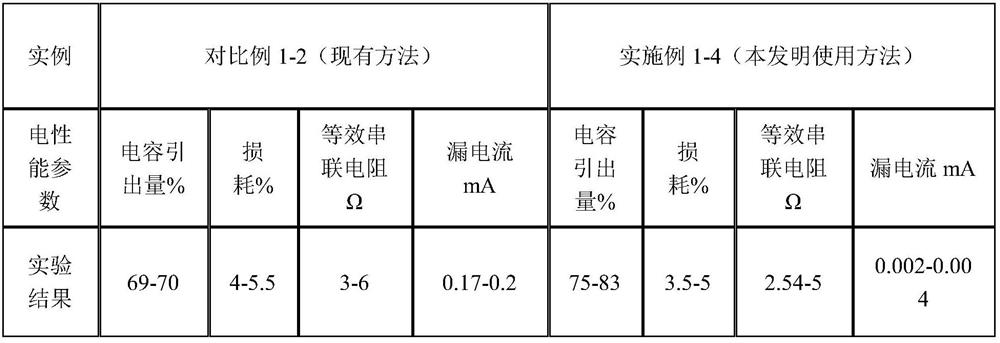

A technology of aluminum electrolytic capacitors and conductive polymers, applied in the direction of solid electrolytic capacitors, electrolytic capacitors, capacitor electrodes, etc., can solve the problems of low capacitor capacity lead-out, equivalent series resistance and large loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) Preparation: Use an aluminum foil slicing mold to cut out 1*1cm with the anode lead-out end 2 The anode foil of the geometric area is formed by supplementing the trimmed edge.

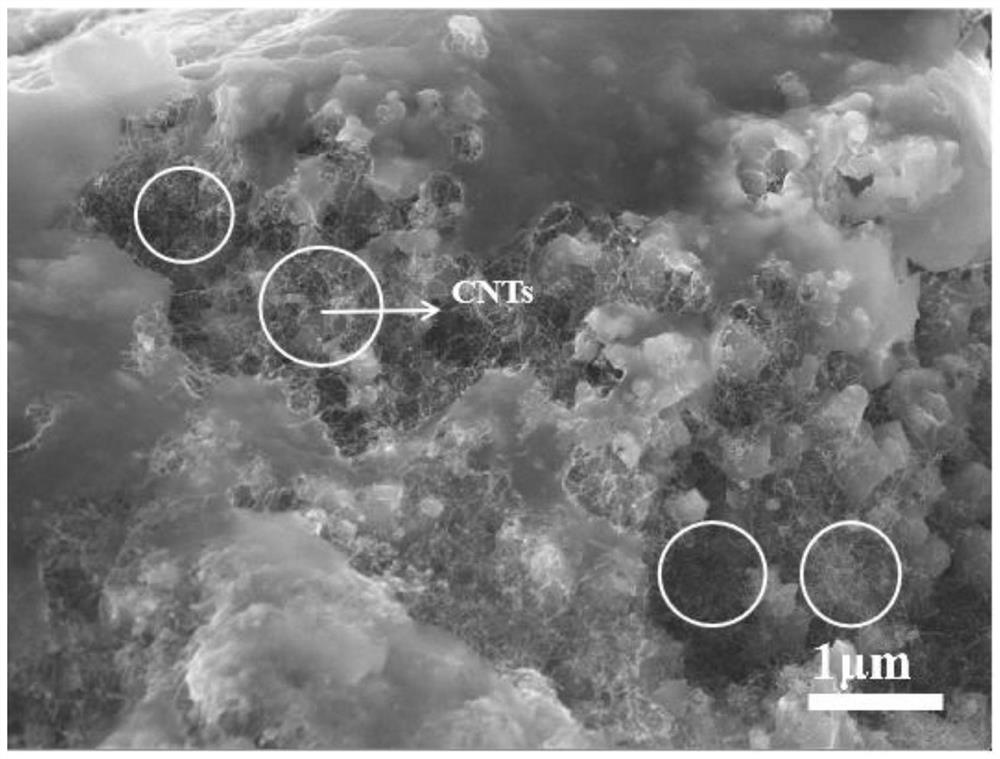

[0044] (2) Depositing the conductive layer of carbon nanotubes by chemical vapor deposition (CVD). Specifically: put the aluminum foil obtained after the treatment in step (1) into the middle of the quartz boat, and push it into the quartz tube (100 cm long, 35 cm inner diameter). With acetylene (C 2 h 2 ) is the carbon source gas, which is grown directly on the aluminum micro-grate by chemical vapor deposition in a horizontal tube furnace. Before heating to the set temperature (600°C), a certain flow rate of argon gas was passed into the furnace for 30 minutes, and the air was exhausted. Carbon source C 2 h 2 The flow rate introduced into the furnace is 50ml min -1. After 15 min of growth, the tube furnace was cooled to room temperature under an argon atmosphere, and the aluminum fo...

Embodiment 2

[0049] (1) Preparation: Use an aluminum foil slicing mold to cut out 1*1cm with the anode lead-out end 2 The anode foil of the geometric area is formed by supplementing the trimmed edge.

[0050] (2) growing a conductive layer of carbon nanotubes on the dielectric layer by chemical vapor deposition (CVD). Specifically: put the aluminum foil obtained after the above step (1) into the middle of the quartz boat, and push it into the quartz tube (100 cm long, 35 cm internal diameter). With acetylene (C 2 h 2 ) is the carbon source gas, which is grown directly on the aluminum micro-grate by chemical vapor deposition in a horizontal tube furnace. Before heating to the set temperature (600°C), a certain flow rate of argon gas was passed into the furnace for 30 minutes, and the air was exhausted. Carbon source C 2 h 2 The flow rate introduced into the furnace is 40ml min -1 . After 20 min of growth, the tube furnace was cooled to room temperature under an argon atmosphere, and...

Embodiment 3

[0055] (1) Preparation: Use an aluminum foil slicing mold to cut out 1*1cm with the anode lead-out end 2 The anode foil of the geometric area is formed by supplementing the trimmed edge.

[0056] (2) A graphene conductive layer is grown on the dielectric layer by chemical vapor deposition technology. Specifically: put the aluminum foil obtained after the above step (1) into the middle of the quartz boat, push it into the quartz tube (100 cm long, 35 cm inner diameter); Into benzene vapor. React at 400°C for 30 minutes to obtain a graphene conductive layer, and take it out after cooling down to room temperature.

[0057] (3) Electrochemical method was used to prepare polypyrrole on the pre-deposited graphene conductive layer. Specifically: at room temperature and pressure, the constant current method (j≤5mA·cm -2 , Potential ≤ 1V (relative to SCE)), the anode aluminum foil obtained after the above step (2) was electroplated in a solution containing 0.5M pyrrole monomer and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com