A kind of all-solid composite electrolyte and its preparation method and application

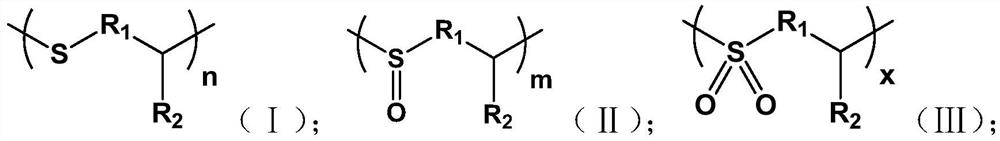

A composite electrolyte, all-solid-state technology, used in solid electrolytes, non-aqueous electrolytes, non-aqueous electrolyte batteries, etc., can solve the problems of unclear key factors of electrochemical stability window, narrow electrochemical window, and poor solid-solid interface performance. Achieve significant performance advantages and features, improve ionic conductivity, and improve antioxidant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

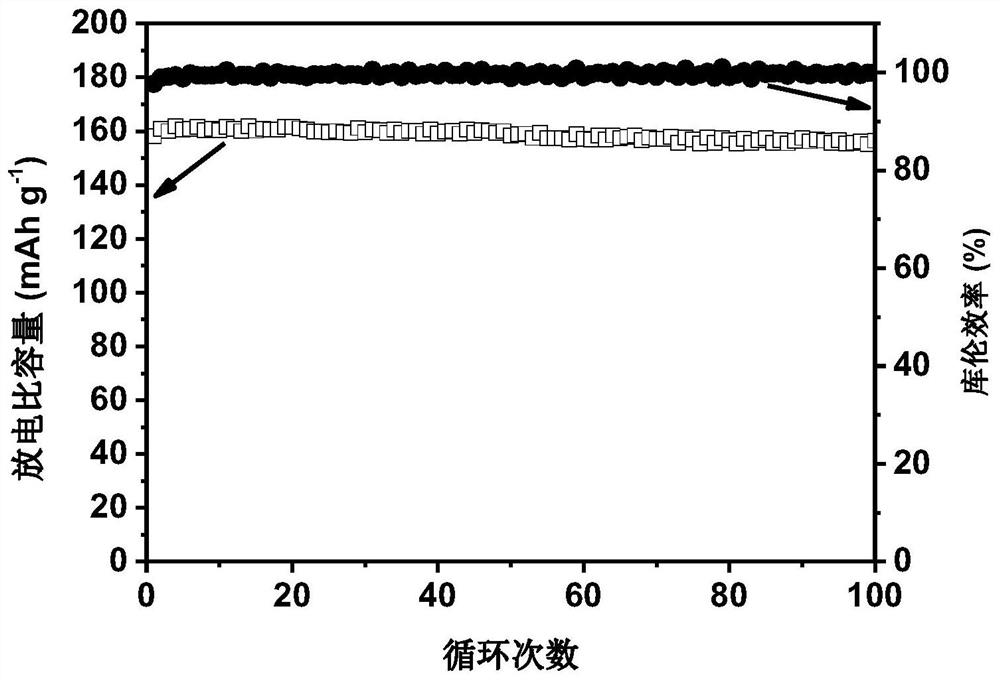

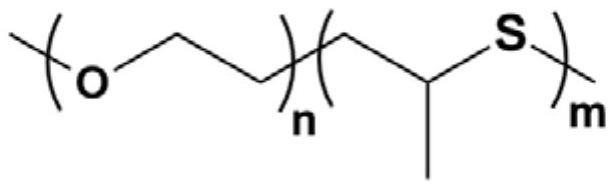

[0056] 0.6 g of dried polypropylene sulfide-polyoxyethylene block copolymer (M w =120000g / mol, the structural formula is shown below), 0.2g of lithium bistrifluorosulfonimide and 50ml of tetrahydrofuran were added to the round-bottomed flask, and then stirred at room temperature for 24h to obtain a homogeneous polymer solution. Then, the mixed solution was dried in a fume hood at room temperature for 2 days and in a vacuum oven at 60°C for 1 day to obtain an all-solid-state composite electrolyte.

[0057]

Embodiment 2

[0059] 0.6 g of dried polypropylene sulfide-polyoxyethylene block copolymer (M w =120000g / mol, the structural formula is shown below), 0.2g lithium bistrifluorosulfonimide, 0.1g SiO 2 and 50 ml of tetrahydrofuran were added to the round-bottomed flask, and then stirred at room temperature for 24 h to obtain a homogeneous polymer solution. Then, the mixed solution was dried in a fume hood at room temperature for 2 days and in a vacuum oven at 60°C for 1 day to obtain an all-solid-state composite electrolyte.

[0060]

Embodiment 3

[0062] 0.6 g of dried polypropylene sulfide-polyoxyethylene block copolymer (M w =120000g / mol, the structural formula is shown below), 0.2g lithium bistrifluorosulfonimide, 0.1g LLZTO and 50ml tetrahydrofuran were added to the round bottom flask, and then stirred at room temperature for 24h to obtain a homogeneous polymer solution. Then, the mixed solution was dried in a fume hood at room temperature for 2 days and in a vacuum oven at 60°C for 1 day to obtain an all-solid-state composite electrolyte.

[0063]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com