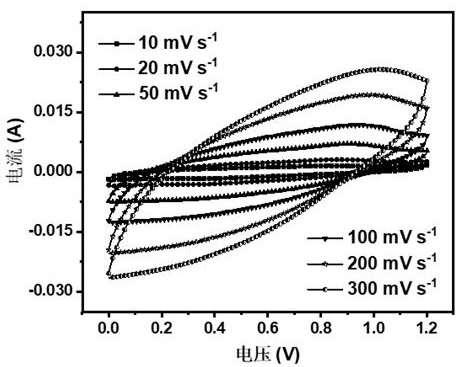

Preparation method of sodium manganese oxide and application of sodium manganese oxide in super capacitor

A technology of sodium manganese oxide and sodium hydroxide, applied in manganese compounds, chemical instruments and methods, hybrid capacitor electrodes, etc., can solve the problems of high economic cost, low output, and complicated process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

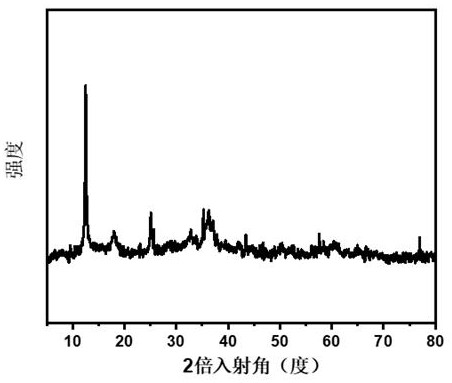

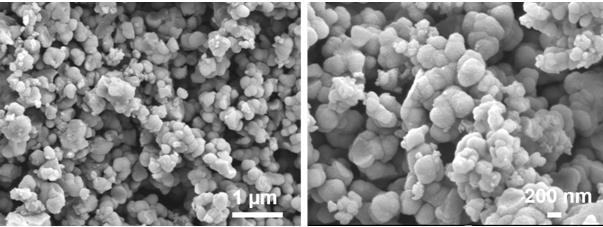

[0029] (1) Weigh 0.8 Kg of sodium hydroxide (NaOH) solution in 12 L of deionized water, 2.45 Kg of manganese acetate tetrahydrate (Mn(CH 3 COO) 2 • 4H 2 O) Dissolved in 3 L of deionized water, while stirring, slowly added manganese acetate tetrahydrate into the sodium hydroxide solution, after the addition of manganese acetate tetrahydrate was completed, stirred at room temperature for 1 h to obtain brown precipitate. Suspension; Then, a precipitate was obtained by suction filtration, and a brown precipitate was obtained at a drying temperature of 80 °C.

[0030] (2) Grind 1 Kg of the above-mentioned brown precipitate and 1 Kg of sodium hydroxide evenly, raise the temperature to 300 ℃ at a rate of 6 ℃ / min in an argon atmosphere, and keep it warm for 10 hours, then cool with the furnace A black sintered product was obtained at room temperature. The above-mentioned sintered product was filtered and washed 6 times to remove sodium-containing by-products in the final product, a...

Embodiment 2

[0032] (1) Weigh 0.8 Kg of sodium hydroxide (NaOH) solution in 12 L of deionized water, 2.45 Kg of manganese acetate tetrahydrate (Mn(CH 3 COO) 2 • 4H 2 O) Dissolved in 3 L of deionized water, while stirring, slowly added manganese acetate tetrahydrate into the sodium hydroxide solution, after the addition of manganese acetate tetrahydrate was completed, stirred at room temperature for 1 h to obtain brown precipitate. Suspension; Then, a precipitate was obtained by suction filtration, and a brown precipitate was obtained at a drying temperature of 80 °C.

[0033] (2) Grind 1 Kg of the above-mentioned brown precipitate and 1 Kg of sodium hydroxide evenly, in an atmosphere of argon, raise the temperature to 450°C at a rate of 6°C / min, keep it warm for 10 hours, and then cool with the furnace A black sintered product was obtained at room temperature. The above-mentioned sintered product was filtered and washed 4 times to remove sodium-containing by-products in the final produc...

Embodiment 3

[0035] (1) Weigh 0.8 Kg of sodium hydroxide (NaOH) solution in 12 L of deionized water, 2.45 Kg of manganese acetate tetrahydrate (Mn(CH 3 COO) 2 • 4H 2 O) Dissolve in 3 L of deionized water, while stirring, slowly add manganese acetate tetrahydrate into the sodium hydroxide solution, after the addition of manganese acetate tetrahydrate is completed, stir at room temperature for 1 h to obtain brown precipitate Suspension; Then, a precipitate was obtained by suction filtration, and a brown precipitate was obtained at a drying temperature of 80 °C.

[0036] (2) Grind 1 Kg of the above-mentioned brown precipitate and 1 Kg of sodium hydroxide evenly, in an atmosphere of argon, raise the temperature to 600 ℃ at a rate of 6 ℃ / min, keep it warm for 10 hours, and then cool with the furnace A black sintered product was obtained at room temperature. The above-mentioned sintered product was filtered and washed 5 times to remove sodium-containing by-products in the final product, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com