Application of multifunctional bacillus coagulans in probiotic nut production

A technology of Bacillus coagulans and probiotics, which is applied in the field of microbial application and food processing, can solve the problems of unpublished Bacillus coagulans strains, application effect verification, etc., and achieve the effects of inhibiting the growth of pathogenic bacteria, high product safety and low hygroscopicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

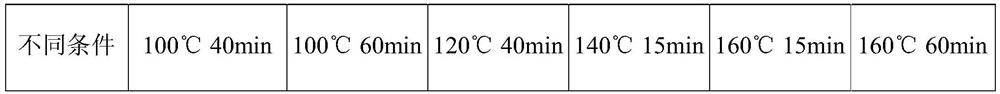

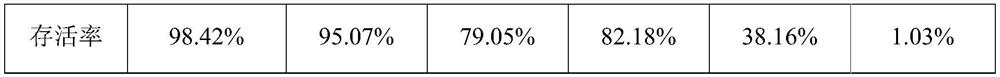

[0053] Screening and performance measurement of embodiment 1 bacillus coagulans

[0054] 1 Screening, identification and storage of strains

[0055] (1) First crush the pickled cabbage, add 15mL sterile water, shake vigorously for 20min, then act in a water bath at 80°C for 20min; The formula is: yeast extract 10.0g / L; beef extract 10.0g / L; peptone 10.0g / L; sodium bicarbonate 1.5g / L; potassium dihydrogen phosphate 1.5g / L; magnesium sulfate heptahydrate 1.0g / L; sulfuric acid Manganese 0.1g / L; calcium chloride 1.0g / L; deionized water 1L), cultured at 45°C for 48h, and selected strains with large colonies and fast growth were further separated and purified by streaking.

[0056] (2) Preserve the isolated and purified bacterial strain obtained in the previous step in a glycerol tube; then take the bacterial liquid and inoculate it in the MRS medium, and cultivate it until the cell concentration is 10 8 cfu / mL, then according to the final concentration of 10 7 The added amount o...

Embodiment 2

[0107] Example 2 Application of multifunctional Bacillus coagulans BC2000 in the production of probiotic nuts

[0108] The method of applying multifunctional Bacillus coagulans BC2000 to the production of probiotic nuts is as follows:

[0109] (1) Preparation of probiotic coating powder:

[0110] Weigh 5 parts of Bacillus coagulans (spore content up to 1×10 9 More than cfu / g, according to the number of parts by mass, the same below) is pre-mixed with 350 parts of glucose powder to ensure that the two are evenly mixed, and then mixed with 350 parts of fermented yogurt powder, 11 parts of malic acid, 16 parts of milk mineral salt, 55 parts Fructose-oligosaccharides and 3 parts of Haematococcus pluvialis are put into a three-dimensional mixer for thorough mixing;

[0111] (2) Mucus preparation:

[0112] Use 5 parts of isomalt, 30 parts of maltodextrin, and 90 parts of water to make a coating solution;

[0113] (3) Probiotic Nut Wrap

[0114] Put 10 parts of peeled walnut ker...

Embodiment 3

[0120] (1) Preparation of probiotic coating powder:

[0121] Weigh 2 parts of Bacillus coagulans and 350 parts of glucose powder for pre-mixing to ensure that the two are evenly mixed, and then mix with 350 parts of fermented yogurt powder, 11 parts of malic acid, 16 parts of milk mineral salt, 55 parts of fructooligosaccharides, and 3 parts of rain Raw Haematococcus are put into the three-dimensional mixer together for thorough mixing;

[0122] (2) Mucus preparation:

[0123] Use 5 parts of isomalt, 30 parts of maltodextrin, and 90 parts of water to make a coating solution;

[0124] (3) Probiotic Nut Wrap

[0125] Put 10 parts of peeled walnut kernels into the coating equipment, and put the mucus into the liquid storage tank at the mucus adding end of the coating equipment. In the powder storage tank, the coating powder addition parameters are: 1 part of coating powder, time 1min, rotation speed set to 40Hz, start the equipment. After 1 minute, the nuts with mucus in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com