Pathological specimen sealing liquid and preparation and sealing methods thereof

A technique for specimens and pathology, which is applied in the field of pathological specimens’ mounting liquid and its preparation and sealing, can solve the problems that affect the needs of follow-up visits or scientific research, cannot meet the needs of use, and affect the health of operators, etc., to achieve the benefits of automated production, Improve the sealing efficiency and good environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

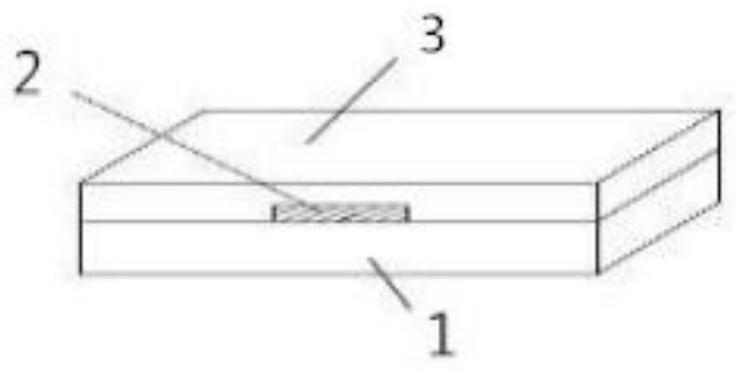

Image

Examples

Embodiment 1

[0032] 1) Use 45 parts of polyester acrylic resin, 5 parts of isobornyl methacrylate, 20 parts of 1,6-hexanediol diacrylate, 15 parts of tripropylene glycol diacrylate, 10 parts of dipentaerythritol hexaacrylate, 1- 2 parts of hydroxycyclohexyl phenyl ketone, 2 parts of 2,4,6-trimethylbenzoyl-diphenylphosphine oxide, 0.5 part of leveling agent BYK333, 0.5 part of defoamer TEGO920, 1 part of coupling agent KH550 and 0.5 part of antioxidant 6026 were used to prepare pathological specimen mounting solution.

[0033] 2) Place the pre-treated specimen slide in a horizontal position, then coat the pathological specimen mounting solution, level it quickly, and irradiate with ultraviolet light to obtain the pathological specimen mounting liquid-sealed glass slide.

[0034] 3) Obtained pathological specimen mounting fluid sealing coating is smooth and flat, and the overall light transmittance is above 90%. Use a pencil hardness tester to test the hardness of the coating, a Chinese dra...

Embodiment 2

[0036] 1) Use 50 parts of polyurethane acrylic resin, 5 parts of isobornyl acrylate, 15 parts of tripropylene glycol diacrylate, 10 parts of trimethylolpropane triacrylate, 10 parts of pentaerythritol triacrylate, 2-hydroxy-2-methyl - 3 parts of 1-phenylacetone, 1 part of phenylbis(2,4,6-trimethylbenzoyl) phosphine oxide, 0.5 part of leveling agent BYK333, 0.5 part of defoamer TEGO920, 1 part of coupling agent KH560, 0.5 part of antioxidant 1010 to prepare pathological specimen mounting solution.

[0037] 2) Place the pre-treated specimen slide in a horizontal position, then coat the pathological specimen mounting solution, level it quickly, and irradiate with ultraviolet light to obtain the pathological specimen mounting liquid-sealed glass slide.

[0038] 3) Obtained pathological specimen mounting fluid sealing coating is smooth and flat, and the overall light transmittance is above 90%. Use a pencil hardness tester to test the hardness of the coating, a Chinese drawing pen...

Embodiment 3

[0040] 1) Use 55 parts of epoxy-modified acrylic resin, 8 parts of hydroxyethyl methacrylate, 10 parts of neopentyl glycol diacrylate, 12 parts of trimethylolpropane triacrylate, 10 parts of dipentaerythritol hexaacrylate, 3 parts of 2-methyl-2-(4-morpholinyl)-1-[4-(methylthio)phenyl]-1-propanone, 2 parts of 2-isopropylthioxanthone, 0.4 parts The pathological specimen mounting solution was prepared by leveling agent TEGO2100, 0.3 part of defoamer KS66, 1 part of coupling agent KH570, and 0.5 part of antioxidant 6026.

[0041] 2) Place the pre-treated specimen slide in a horizontal position, then coat the pathological specimen mounting solution, level it quickly, and irradiate with ultraviolet light to obtain the pathological specimen mounting liquid-sealed glass slide.

[0042] 3) The obtained pathological specimen mounting liquid sealing coating is smooth and flat, and the overall light transmittance is above 91%. Use a pencil hardness tester to test the hardness of the coat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com