Three-dimensional ordered macroporous graphene carbon material embedded with MoSx nanosheets, preparation and application

A three-dimensional ordered, nano-sheet technology, applied in active material electrodes, electrical components, electrochemical generators, etc., can solve problems such as flexible regulation of difficult physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

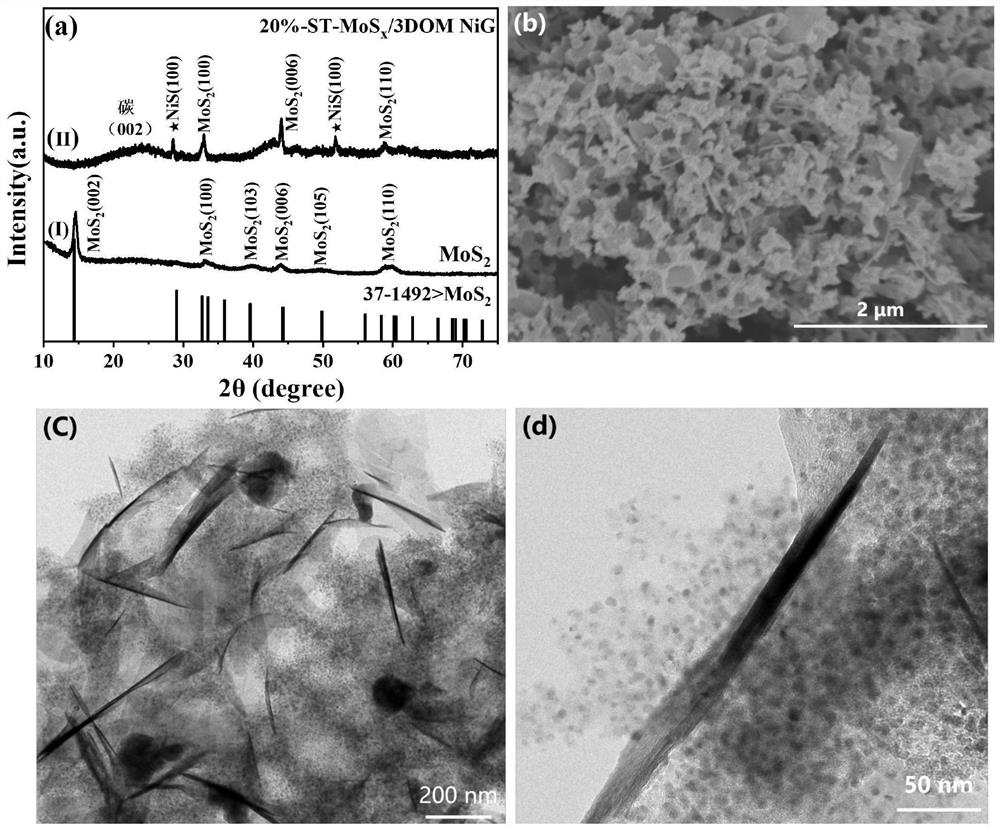

[0025] First, add 0.2mol nickel nitrate and 0.1mol citric acid into 100ml deionized water, stir to form a homogeneous solution; secondly, weigh 10g polymethyl methacrylate (PMMA) microsphere template and add it to the above solution, and let it stand for 12h Suction filtration; then, put the impregnated precursor into a 50°C drying oven to dry; finally, place it in a tube furnace and roast it in an argon atmosphere, and raise the temperature to 500°C at a rate of 5°C / min and keep it warm for 0.5 h, Three-dimensional ordered macroporous structure carbon material 3DOM NiG was obtained after natural cooling to room temperature. A certain amount of 3DOM NiG was weighed as a carbon matrix and added to an aqueous solution of ammonium tetrathiomolybdate (20 wt.% of the former), and transferred to a reactor for hydrothermal reaction at 200°C for 12 hours. After the reaction was complete, the obtained material was taken out and washed three times with deionized water (centrifuged at 40...

Embodiment 2

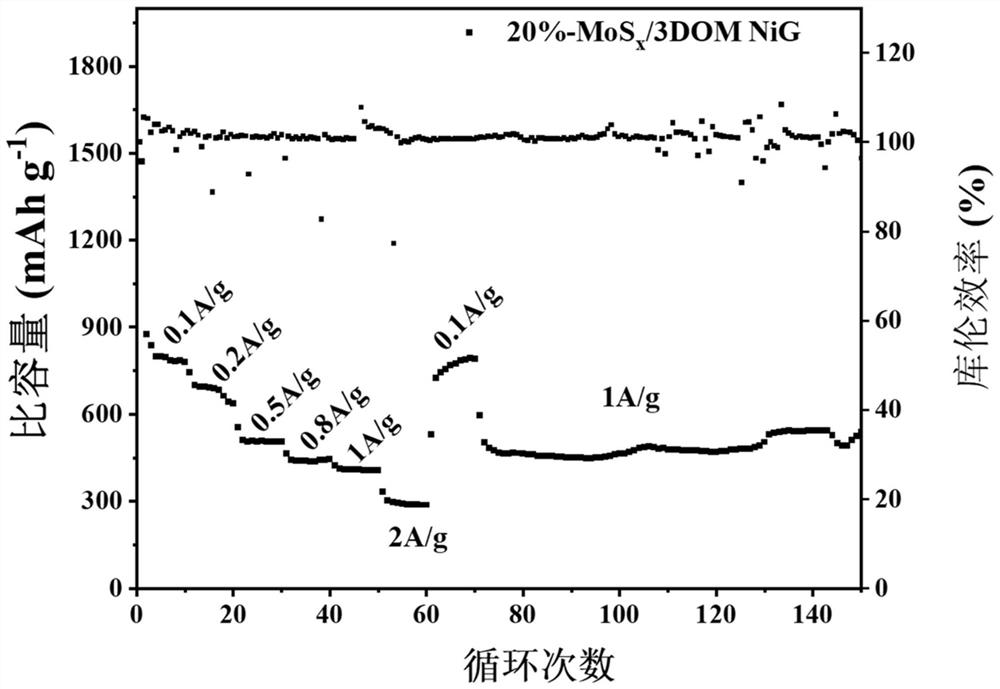

[0027] in an argon-protected glove box (H 2 O2x / 3DOM NiG composite material, conductive carbon black and PVDF are mixed and ground at a mass ratio of 8:1:1 until the components are uniform, then NMP solution is added and stirred evenly, and then the negative electrode slurry is applied on the copper foil with a scraper, and put Dry in an oven at 80°C, and then use a punching machine to obtain pole pieces. Lithium foil is used as the counter electrode, PP is used as the diaphragm, and LiPF with a concentration of 1mol / L 6 The solution is an electrolyte (the solvent is a mixture of EC and DE with a volume ratio of 1:1), and a button-type lithium-ion test battery is assembled. The electrochemical performance test was carried out at room temperature, and the voltage range was 0.01-3.0V. according to figure 2 Test results, when the current density is 0.1A / g, 0.2A / g, 0.5A / g, 1A / g and 2A / g, the prepared 20%-ST-MoS x The average reversible specific capacities of / 3DOM NiG compos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com