Polyaryletherketone resin and synthesis method thereof

A polyaryletherketone and compound technology, applied in the field of polymer materials, can solve the problems of inability to obtain high molecular weight polymers, inaccurate polymerization reaction ratio, etc., and achieve the effects of improving mechanical properties, shortening reaction time, and improving crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Embodiment 1: Utilize the specific embodiment of polyaryletherketone resin synthesized by end-capping of oligomer

[0056] 1.1 The preparation of the capping agent is as follows:

[0057] Add 4.0 kg of diphenyl sulfone to a reaction kettle protected by inert gas, melt it to 160°C, add 1.3083 kg of 4,4'-difluorobenzophenone, and 0.636 kg of sodium carbonate, heat it to 160°C, add terephthalate 0.5505 kg of phenol. The temperature of the reaction system was raised to 210°C for 2 hours, 250°C for 1 hour, and 305°C for 1 hour.

[0058] According to the binary polycondensation theory and infrared characterization, the synthesized structure is as follows:

[0059]

[0060] 1.2 Synthesis of polyaryletherketone resin

[0061] Diphenylsulfone (672 kg) was added to the kettle. Reduced pressure and evacuated to 0.2 MPa, and fed nitrogen to normal pressure. Under nitrogen protection, heat to 160°C. Then add 127.2 kilograms of sodium carbonate, 218.050 kilograms of 4,4'-dif...

Embodiment 2

[0062] Embodiment 2: Specific examples of synthesis of unblocked polyaryletherketone resin

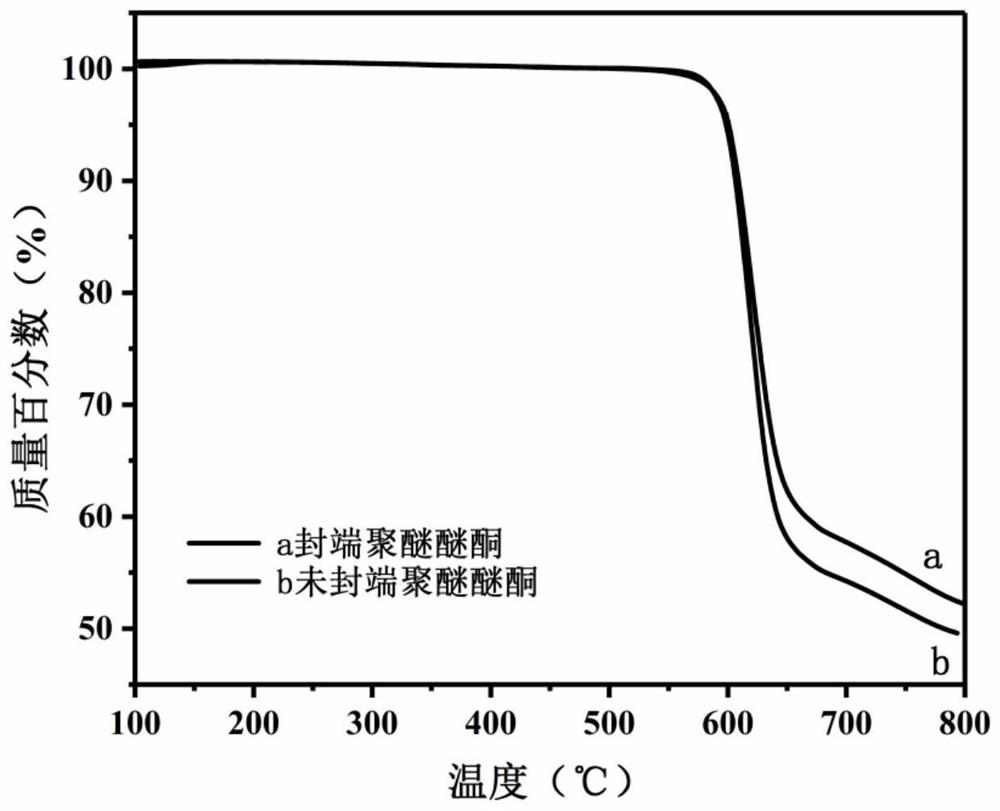

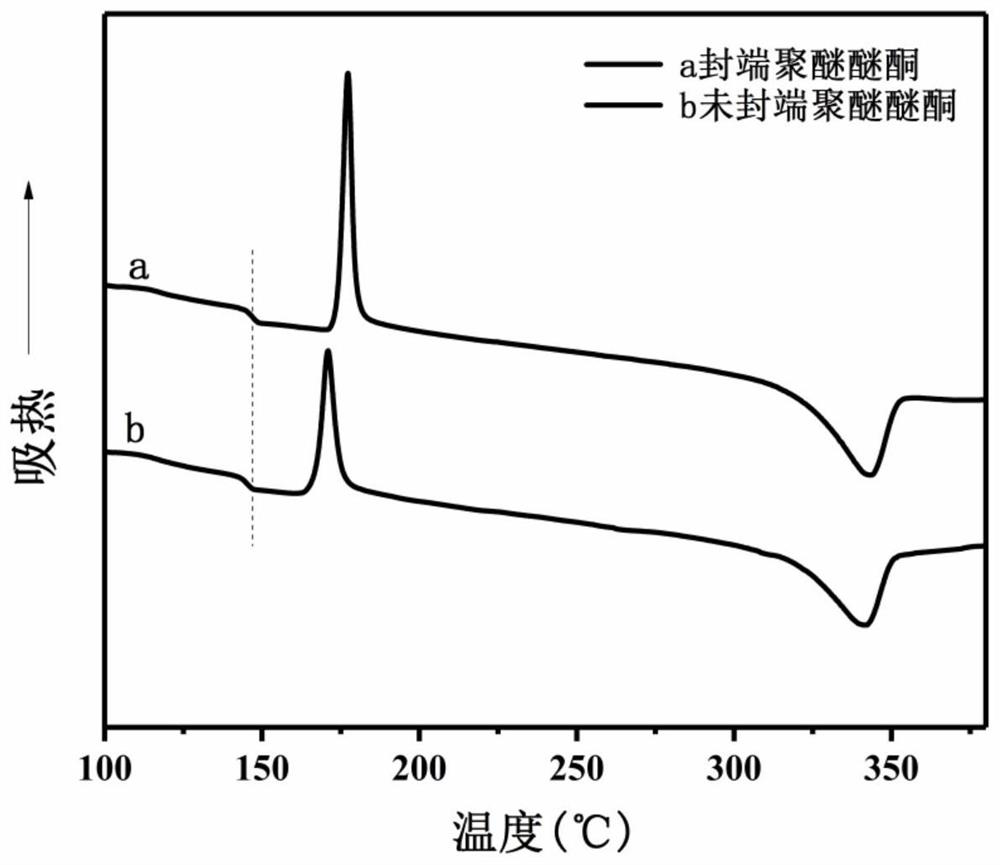

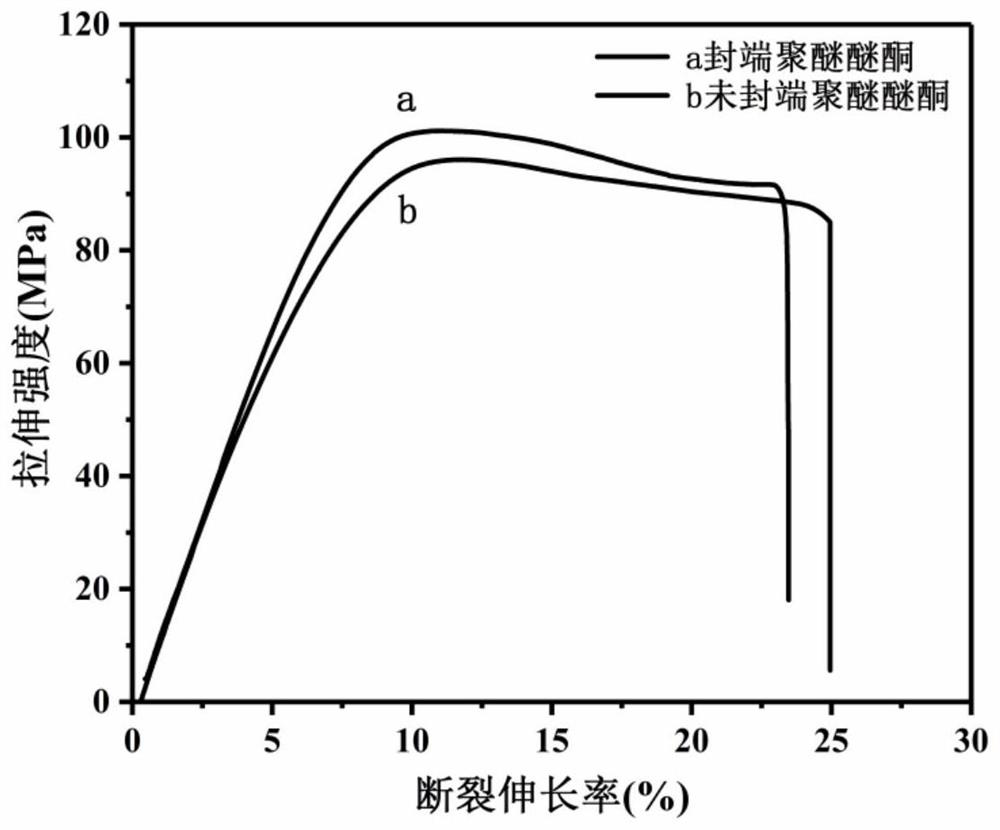

[0063] Diphenylsulfone (672 kg) was added to the kettle. Reduced pressure and evacuated to 0.2 MPa, and fed nitrogen to normal pressure. Under nitrogen protection, heat to 160°C. Add 127.2 kilograms of sodium carbonate, 219.140 kilograms of 4'-difluorobenzophenone and 110.110 kilograms of hydroquinones again. The reaction kettle was heated to 220°C for 2 hours, 250°C for 1 hour, 290°C for 1 hour, and 310°C for 3 hours. The polymer is cooled, pulverized, extracted with ethanol or acetone to constant weight, extracted with distilled water to constant weight, and dried. The materials were analyzed for intrinsic viscosity, differential thermal scanner (DSC), and thermogravimetric loss (TGA) and tensile properties. Its thermal and mechanical properties compared with the blocked polyaryletherketone resin are as follows: figure 1 , figure 2 and image 3 shown.

Embodiment 3

[0064] Embodiment 3: Utilize the specific embodiment of polyaryletherketone resin synthesized by end-capping of oligomer

[0065] The synthesis of polyaryletherketone resin is the same as in Example 1, except that the end-capping agent is different. The product analysis results are shown in Table 1.

[0066] The preparation method of end-capping agent is:

[0067] Add 4 kg of diphenyl sulfone to a reactor protected by inert gas, melt it to 160°C, add 1.5264 kg of 4,4'-difluorobenzophenone, and 0.636 kg of sodium carbonate, heat it to 160°C, add terephthalate 0.5505 kg of phenol. The temperature of the reaction system was raised to 210°C for 2 hours, 250°C for 1 hour, and 305°C for 1 hour.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com