Starch-based edible film and preparation method thereof

A starch-based, potato starch-based technology, applied in sustainable manufacturing/processing, climate sustainability, sustainable packaging, etc., can solve the problems of cumbersome process and many chemical raw materials, and achieve good light transmission and dense network structure , Increase the effect of compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

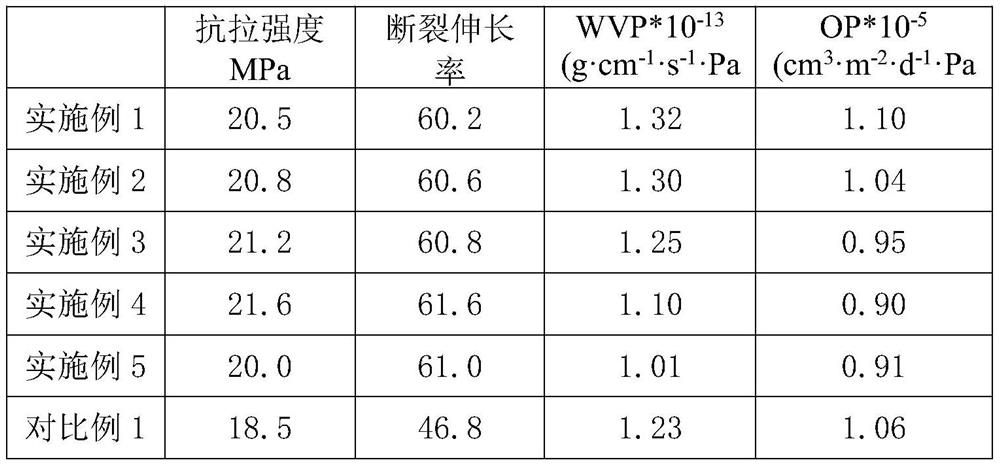

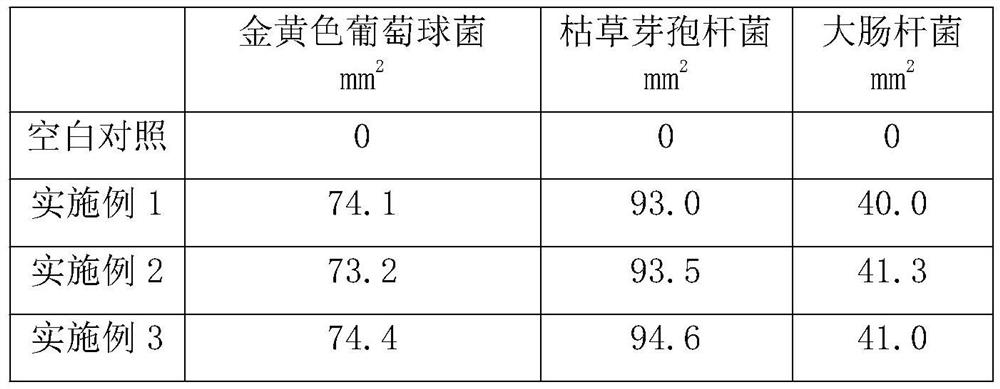

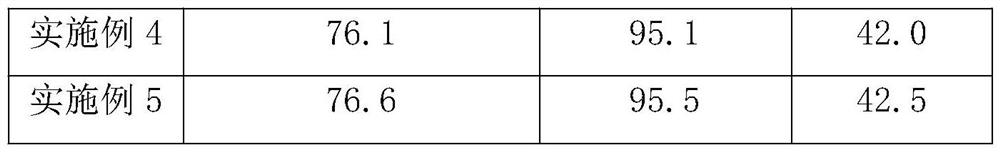

Examples

Embodiment 1

[0027] A starch-based edible film, made of the following raw materials in parts by weight: 3 parts of cross-linked potato starch, 2 parts of soybean protein isolate, 1 part of emulsifier, 1 part of glycerin, 0.2 parts of calcium carbonate whiskers, myristic acid 0.1 part, 0.2 part of antibacterial agent, 90 parts of water.

[0028] The preparation method of the cross-linked potato starch comprises the following steps: the potato starch is dispersed in water to form a 35wt% starch emulsion, placed in a constant temperature water bath at 45°C and the pH is controlled to be 8.0-9.0, and octyl succinic anhydride is added dropwise Ethanol solution, stirred and reacted for 1-1.5 hours, then added sodium trimetaphosphate, stirred for 2 hours, the product was washed, dried and pulverized to obtain cross-linked potato starch;

[0029] The weight percentage of the potato starch, sodium trimetaphosphate and octyl succinic anhydride is 100:0.3:2.

[0030] The antibacterial agent is a mix...

Embodiment 2

[0038] A starch-based edible film, made of the following raw materials in parts by weight: 3.5 parts of cross-linked potato starch, 1.8 parts of soybean protein isolate, 1.2 parts of emulsifier, 1.2 parts of glycerin, 0.25 parts of calcium carbonate whiskers, nutmeg 0.12 parts of acid, 0.22 parts of antibacterial agent, and 90 parts of water.

[0039] The preparation method of the cross-linked potato starch comprises the following steps: the potato starch is dispersed in water to form a 35wt% starch emulsion, placed in a constant temperature water bath at 45°C and the pH is controlled to be 8.0-9.0, and octyl succinic anhydride is added dropwise Ethanol solution, stirred and reacted for 1-1.5 hours, then added sodium trimetaphosphate, stirred for 2 hours, the product was washed, dried and pulverized to obtain cross-linked potato starch;

[0040] The weight percentage of the potato starch, sodium trimetaphosphate and octyl succinic anhydride is 100:0.3:2.

[0041]The antibacte...

Embodiment 3

[0046] A starch-based edible film, made of the following raw materials in parts by weight: 4 parts of cross-linked potato starch, 1.5 parts of soybean protein isolate, 1.5 parts of emulsifier, 1.5 parts of glycerin, 0.3 parts of calcium carbonate whiskers, nutmeg 0.15 parts of acid, 0.25 parts of antibacterial agent, and 92 parts of water.

[0047] The preparation method of the cross-linked potato starch comprises the following steps: the potato starch is dispersed in water to form a 35wt% starch emulsion, placed in a constant temperature water bath at 45°C and the pH is controlled to be 8.0-9.0, and octyl succinic anhydride is added dropwise Ethanol solution, stirred and reacted for 1-1.5 hours, then added sodium trimetaphosphate, stirred for 2 hours, the product was washed, dried and pulverized to obtain cross-linked potato starch;

[0048] The weight percentage of the potato starch, sodium trimetaphosphate and octyl succinic anhydride is 100:0.3:2.5.

[0049] Other process...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com