Laminated electrochemical reactor and application thereof in electrolytic synthesis of succinic acid

A reactor and electrochemical technology, which is applied in stacked electrochemical reactors and its application in the electrolytic synthesis of succinic acid, can solve the problems of high energy consumption, short circuit, low volume utilization, etc., and reach the electrode area Larger, lower tank pressure, lower energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

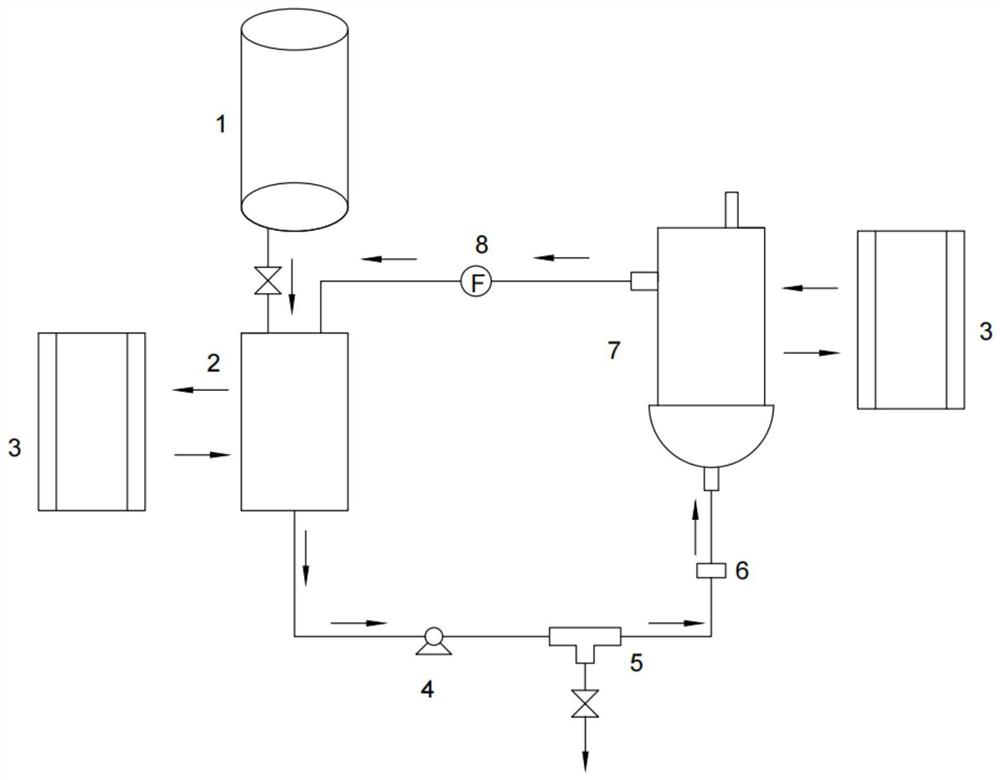

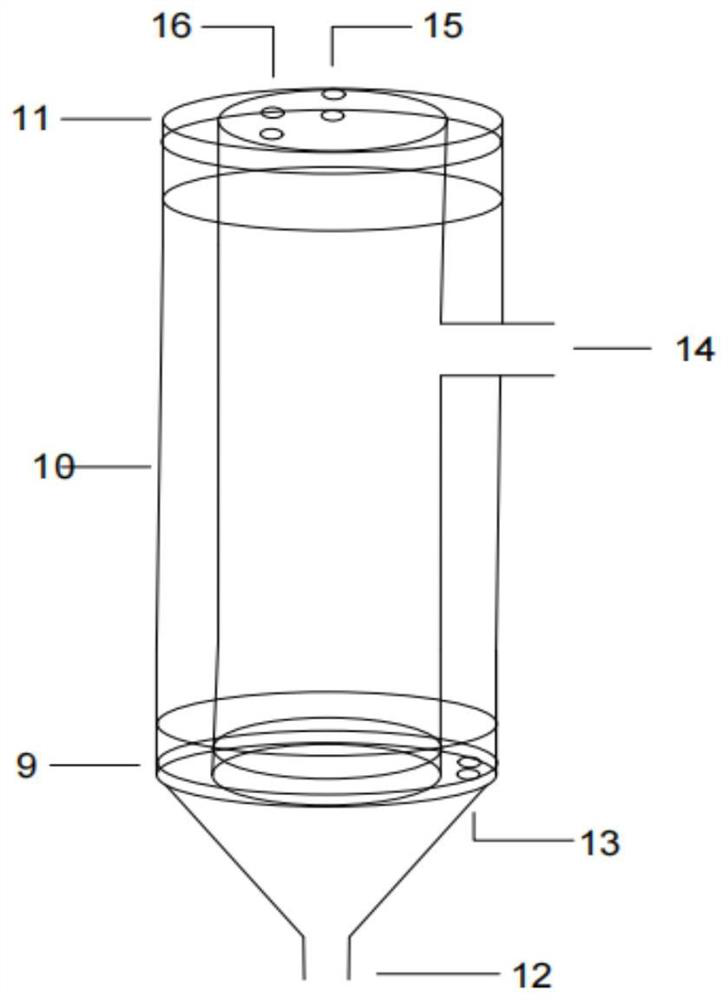

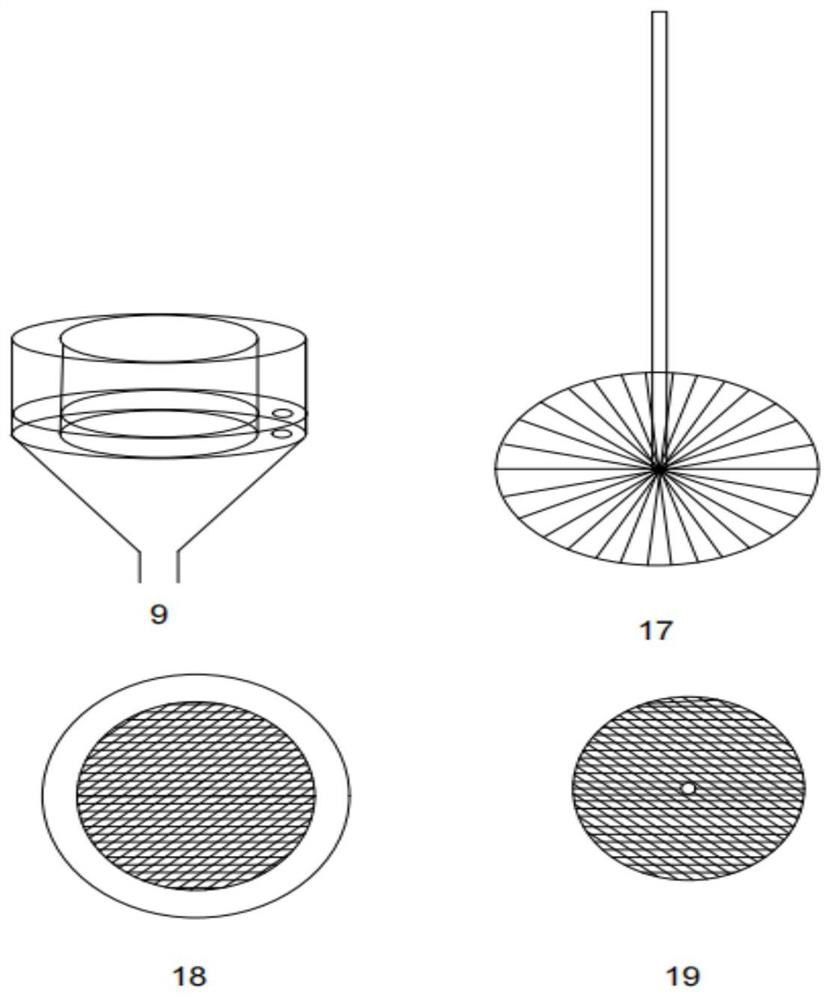

Embodiment 1

[0065] Deionized water was used to prepare 350g of the original electrolyte. The composition of the original electrolyte was 9.8% maleic anhydride mass concentration and 5% sulfuric acid mass concentration. The cathode material was titanium mesh, and the anode was a titanium-based ruthenium-iridium electrode. The temperature of the electrolyte is controlled at 50°C; the number of cathode stacks is 1; the apertures of the cathode and anode mesh are 2mm and 2.5mm respectively, the porosity is 50%, the thickness of each sheet is 1mm, and the anode current density is 1000A / m 2 , J 阳 / J 阴 = 1:1; the electrolysis electricity is 100% of the theoretical electricity. At the beginning of electrolysis, the prepared electrolyte is fed from the high-level liquid storage tank to the circulation tank, and the electrolyte forms a closed loop of circulation through the magnetic circulation pump. When the thermometer reading is stable at 50°C, the electrolysis starts. After the electrolysis, ...

Embodiment 2

[0067] The electrolysis device, electrolysis method, electrolysis temperature, anode current density, cathode and anode porosity, pore size, single sheet thickness, input power, initial composition and quality of the electrolyte are the same as in Example 1; the number of cathode stacks is 3, and the cathode stack The spacing is 1 mm, J positive / J negative = 3:1; after the electrolysis, the electrolyzed solution is placed in the refrigerator, crystallized at -2°C for 90 minutes, filtered, and dried to obtain 30.12 g of succinic acid crystals, succinic acid The acid purity is 99.43%, the electrolysis voltage is 2.25-2.2.55V, the current efficiency is 74.2%, and the reduction yield of succinic acid is 74.2%.

Embodiment 3

[0069] Electrolysis device, electrolysis method, electrolysis temperature, anode current density, cathode and anode porosity, pore size, monolithic thickness, cathode stack spacing, input electricity, initial composition and quality of electrolyte are the same as embodiment 2; the number of cathode stacks is 5,J 阳 / J 阴 =5:1; After the electrolysis is finished, the electrolytic solution is placed in a refrigerator, crystallized at -2°C for 90 minutes, filtered, and dried to obtain 30.82g of succinic acid crystals, the purity of succinic acid is 99.61%, and the electrolysis voltage is 2.20- 2.48V, the current efficiency is 75.9%, and the reduction yield of succinic acid is 75.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com