Cu2O/Cu9S5 photocatalytic material with hollow spherical structure as well as preparation method and application of Cu2O/Cu9S5 photocatalytic material

A photocatalytic material and photocatalyst technology, applied in the field of photocatalytic materials and environmental pollution control, can solve the problems of rapid photo-generated electron-hole recombination, easy to be corroded by light, unstable degradation performance of organic matter, etc. The effect of hole recombination rate, favorable adsorption, and broadening the visible light response range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] A Hollow Spherical Cu for Organic Dye Wastewater Degradation 2 O / Cu 9 S 5 The preparation method of photocatalyst comprises the following steps:

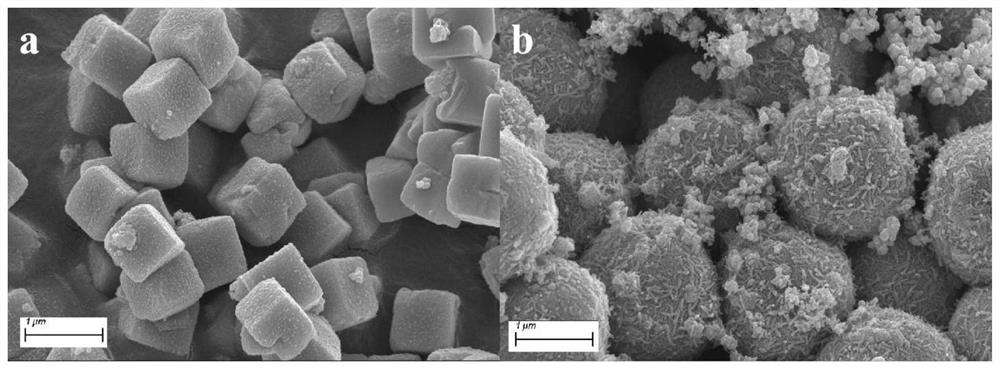

[0032] (1) Preparation of Cu by chemical reduction method 2 O photocatalyst

[0033] The reaction temperature was set at 60°C, and 16 mL of 2 mol / L sodium hydroxide aqueous solution was added dropwise to 20 mL of 0.5 mol / L copper chloride aqueous solution. After stirring and reacting for 30 minutes, 8 mL of 1.25M aqueous glucose solution was added dropwise to the above system solution. Then continue to stir the mixed solution at a constant temperature of 60 °C for 3 hours until the color of the mixed solution gradually turns brick red and forms a stable precipitate, indicating that Cu has been successfully prepared. 2 O. The obtained product was centrifuged and soaked in deionized water and absolute ethanol to remove impurities within 24 hours, washed repeatedly for more than 3 times, and transferred to a vacuum drying ...

Embodiment 1

[0041] Preparation of Cu 2 O photocatalyst:

[0042] The reaction temperature was set at 60°C, and 16 mL of 2 mol / L sodium hydroxide aqueous solution was added dropwise to 20 mL of 0.5 mol / L copper chloride aqueous solution. After stirring and reacting for 30 minutes, 8 mL of 1.25M aqueous glucose solution was added dropwise to the above system solution. Then continue to stir the mixed solution at a constant temperature of 60 °C for 3 hours until the color of the mixed solution gradually turns brick red and forms a stable precipitate, indicating that Cu has been successfully prepared. 2 O. The obtained product was centrifuged and soaked in deionized water and absolute ethanol to remove impurities within 24 hours, washed repeatedly for more than 3 times, and transferred to a vacuum drying oven for 5 hours at 80°C to obtain Cu 2 O, crushed evenly for later use.

[0043] Take 0.4gCu 2 O was placed in a reactor filled with simulated wastewater, and after 2.5h (dark reaction 3...

Embodiment 2

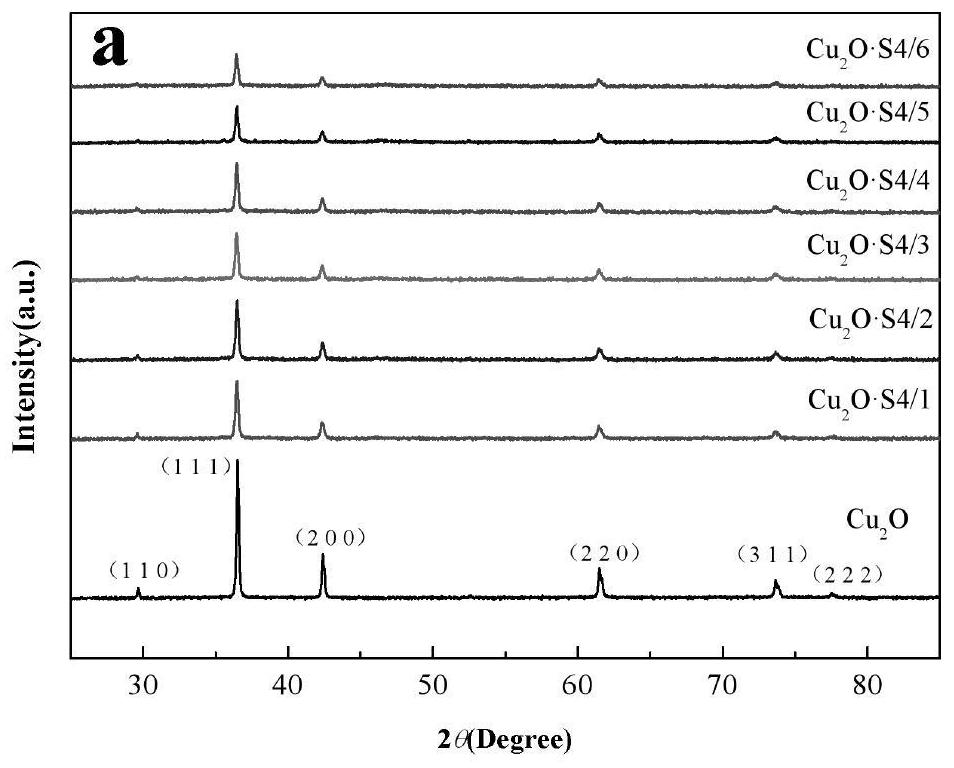

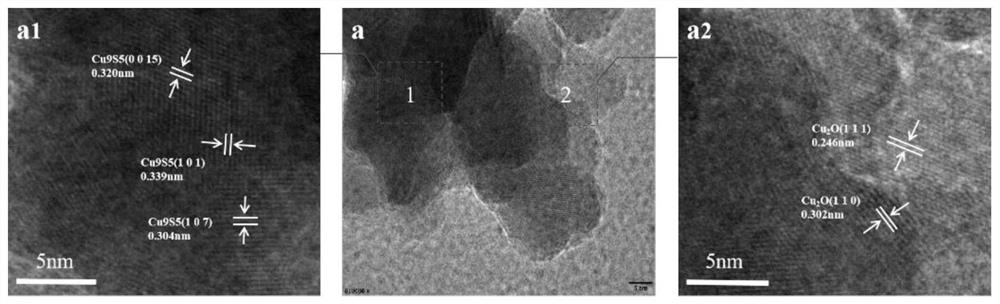

[0045] Preparation of Cu 2 O / Cu 9 S 5 Photocatalyst (Cu 2 The mass ratio of O to thiourea is 4 / 1, denoted as Cu 2 O·S4 / 1):

[0046] Take by weighing the Cu prepared by 0.4g embodiment 1 2 O was dissolved in 10 mL of deionized water to form a turbid solution. Weighed 0.1 g of thiourea and dissolved it in 10 mL of ethanol, added it to the above system, and stirred and reacted in a water bath at 60 °C. After reacting for a certain period of time, the reaction product was centrifuged within 24 hours, soaked and washed with deionized water and ethanol for more than three times, and placed in a vacuum drying oven at 80°C for 5 hours to obtain S-doped modified Cu 2 O·S photocatalytic materials.

[0047] Take 0.4g modified Cu 2 The O·S photocatalytic material was placed in a reactor filled with simulated wastewater. After 2.5 hours (30 minutes of dark reaction + 2 hours of light reaction), the degradation rate of MO was as follows: Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com