Underwater epoxy resin curing agent and preparation method thereof

A technology of epoxy resin curing and amine curing agent, which is applied in the field of polymer material synthesis and preparation, can solve the problems of poor curing performance and environmental protection of curing agent in water, and improve weather resistance, environmental protection and weather resistance. Excellent, simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

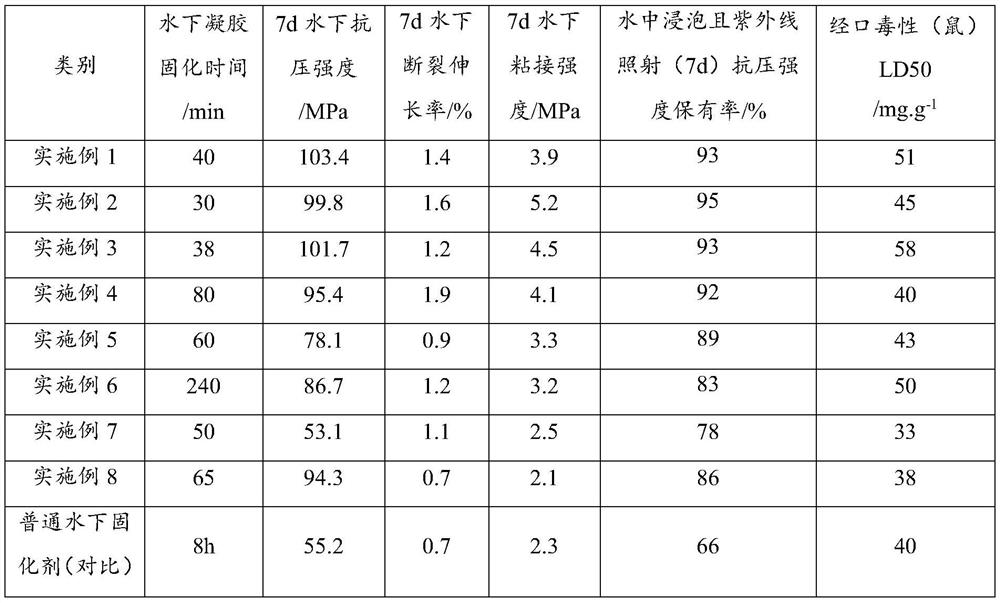

Examples

Embodiment 1

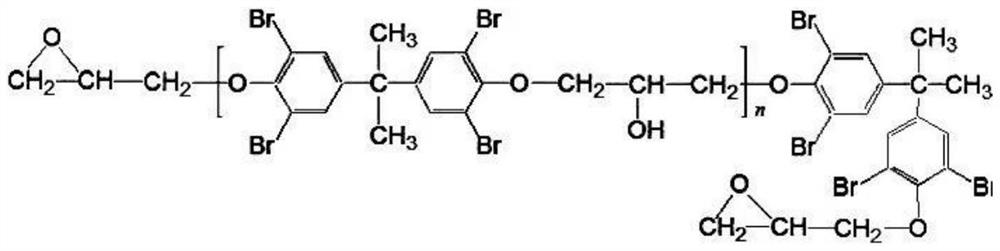

[0025] Diethylene triamine, neopentyl glycol diglycidyl ether, highly brominated DGEBA with a relative molecular weight of 1400, tris(dimethylaminomethyl)phenol, dibutyl phthalate, methyl hydrogen silicone oil according to The mass ratio is 60:15:15:5:3:2 for weighing. First, mix and stir neopentyl glycol diglycidyl ether and highly brominated DGEBA with a relative molecular weight of 1400, then add diethylenetriamine curing agent, and stir for 3 hours at 50°C; when the temperature is cooled to room temperature, add The weighed tris(dimethylaminomethyl)phenol, dibutyl phthalate and methyl hydrogen-containing silicone oil can be continuously mixed and stirred.

Embodiment 2

[0027] Triethylenetetramine, hexanediol diglycidyl ether, hyperbrominated DGEBA with a relative molecular weight of 1400, hyperbrominated DGEBA with a relative molecular weight of 2000, tris(dimethylaminomethyl)phenol, dioctyl phthalate and methyl hydrogen-containing silicone oil are weighed according to the mass ratio of 60:20:5:5:6:2:2. First, mix and stir hexanediol diglycidyl ether and highly brominated DGEBA with a relative molecular weight of 1400, then add triethylenetetramine curing agent, stir and react at 65°C for 2 hours; wait for the temperature to cool to room temperature, add and weigh Good tris(dimethylaminomethyl)phenol, dioctyl phthalate and methyl hydrogen-containing silicone oil continue to mix and stir.

Embodiment 3

[0029] Triethylenetetramine, hexanediol diglycidyl ether, high brominated DGEBA with a relative molecular weight of 1600, dimethylaminomethylphenol, dioctyl phthalate and methyl hydrogen-containing silicone oil are in a mass ratio of 70: 30:10:5:2:3 Weighing. First, mix and stir hexanediol diglycidyl ether and highly brominated DGEBA with a relative molecular weight of 1600, then add triethylenetetramine curing agent, stir and react at 45°C for 4 hours; wait for the temperature to cool to room temperature, add and weigh Good dimethylaminomethylphenol, dioctyl phthalate and methyl hydrogen silicone oil can be mixed and stirred.

PUM

| Property | Measurement | Unit |

|---|---|---|

| amine value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com