Preparation method and application of zeolite type phosphorus removal agent for high-salt waste liquid

A technology of high-salt waste liquid and phosphorus removal agent, which is applied in the directions of crystalline aluminosilicate zeolite, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of low phosphorus removal rate and long hydrothermal time, etc. Efficiency, ease of operation, simple effect of preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

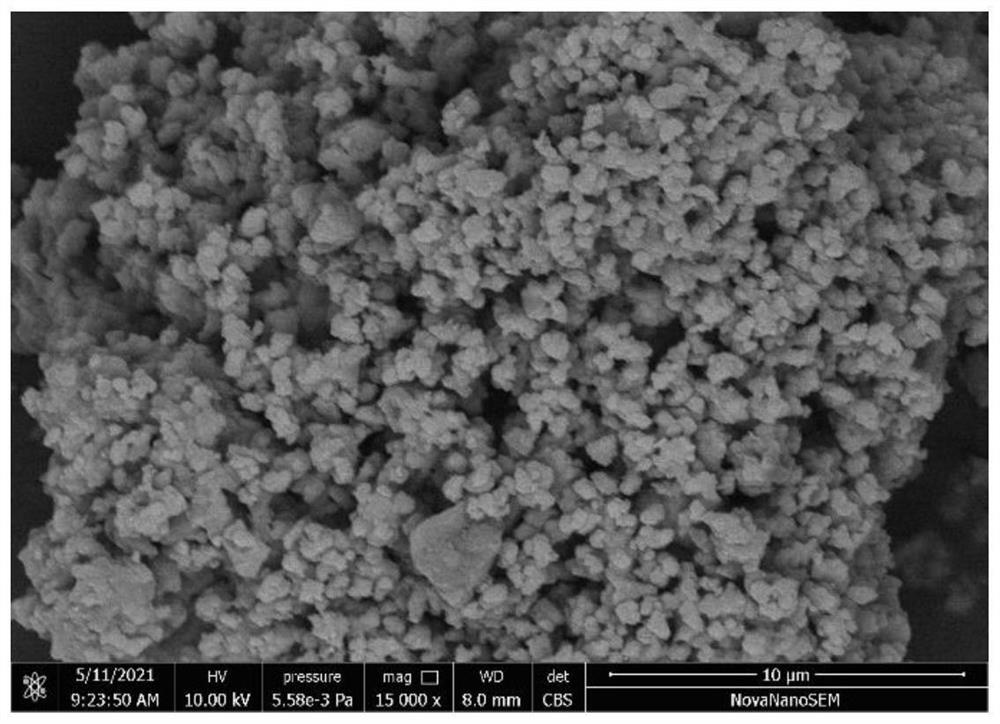

[0028] Preparation of zeolite phosphorus removal agent:

[0029] (1) Nickel slag is purchased from Jiangsu Yancheng Xiangshui Delong Nickel Industry Co., Ltd., kaolin is purchased from Henan Hengyuan New Material Co., Ltd., ball milled to 200 mesh nickel slag, and nickel slag and kaolin are mixed evenly according to the ratio of 7.5:17.5. Mix with sodium hydroxide at a mass ratio of 1:1, add distilled water and a magnetic stirrer at 80°C for 2 hours at a liquid-solid ratio of 200mL / 25g to obtain a mixed slurry;

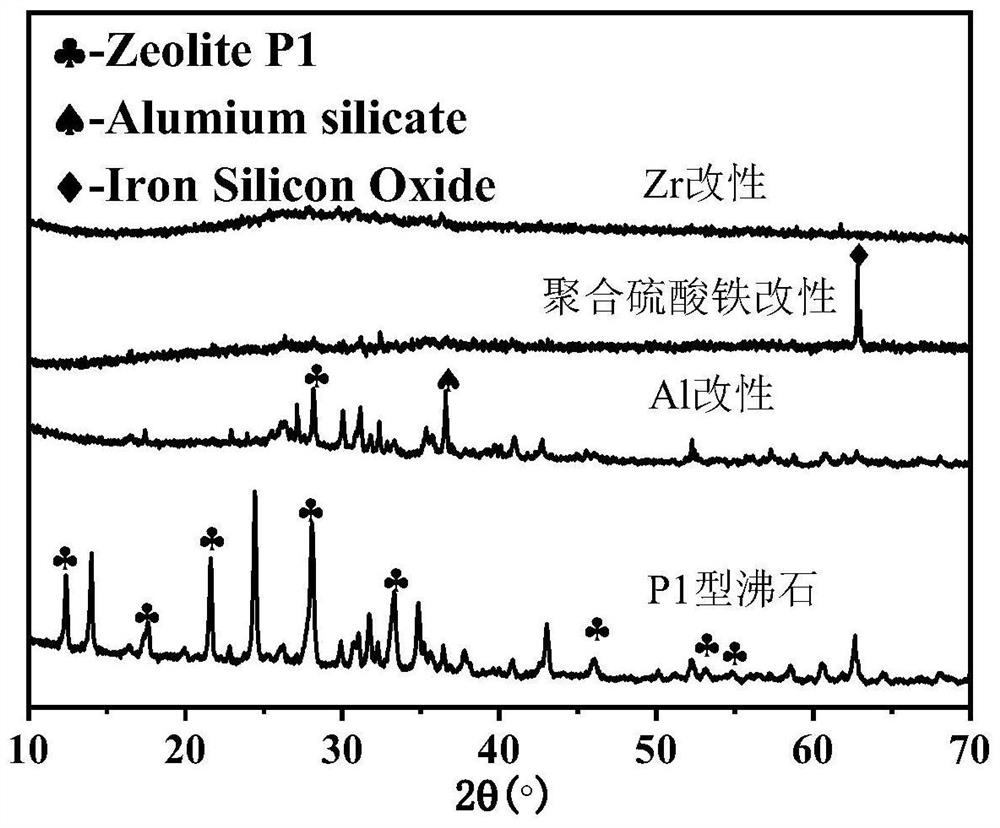

[0030] (2) Put the above mixed slurry into 120° C. and heat it in a reactor for 6 hours, filter, wash and dry the reacted material to obtain P1 zeolite;

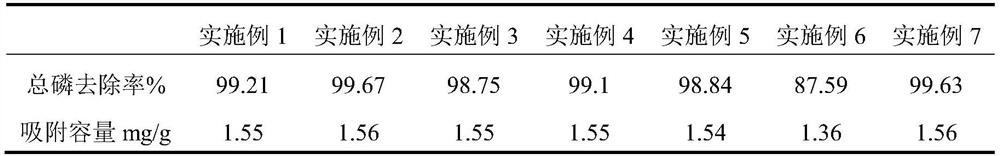

[0031] (3) the above-mentioned P1 type zeolite, and AlCl 3 6H2O was mixed vigorously in a magnetic stirrer at room temperature for 24 hours according to the mass ratio of 1:1 and the solid-to-liquid ratio of 10g / 100mL, then filtered, washed, and dried to obtain a modified zeolite dephosphorization agent, wherein th...

Embodiment 2

[0034] Preparation of zeolite-type dephosphorization agent: Step (1) is the same as in Example 1, (2) put the above mixed slurry in a reactor at 95°C for 7 hours, filter, wash and dry the reacted material to obtain P1 Zeolite; (3) P1 type zeolite, with polyferric sulfate in a mass ratio of 1:1, with a solid-to-liquid ratio of 10g / 100mL, was vigorously mixed in a magnetic stirrer at room temperature for 24 hours, filtered, washed, and dried to obtain a modified zeolite-removed Phosphorus agent, wherein the amount of washing water is 40ml of distilled water per 1g of modified zeolite material.

[0035] Dephosphorization effect measurement: The measurement procedure is the same as in Example 1, and the dephosphorization results are shown in Table 1.

Embodiment 3

[0037] Preparation of zeolite-type dephosphorization agent: Step (1) is the same as in Example 1, (2) put the above mixed slurry into a reactor at 145°C for 6 hours, filter, wash and dry the reacted material to obtain P1 Zeolite; In step (3), P1 type zeolite, with ZrOCl 2 ·8H 2 O according to the mass ratio of 1:1, solid-to-liquid ratio of 10g / 100mL, mixed vigorously in a magnetic stirrer at room temperature for 20h, filtered, washed, and dried to obtain a modified zeolite dephosphorization agent.

[0038] Dephosphorization effect measurement: The measurement procedure is the same as in Example 1, and the dephosphorization results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com