Insulating tape capable of self-melting with cross-linked polyethylene and its preparation process

A technology of cross-linked polyethylene and insulating tape, which is applied in the direction of climate change adaptation, etc., can solve the problems of low temperature performance, reduced insulation performance, and low compressive strength, and achieves simple preparation process, wide application range, and high compressive strength. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

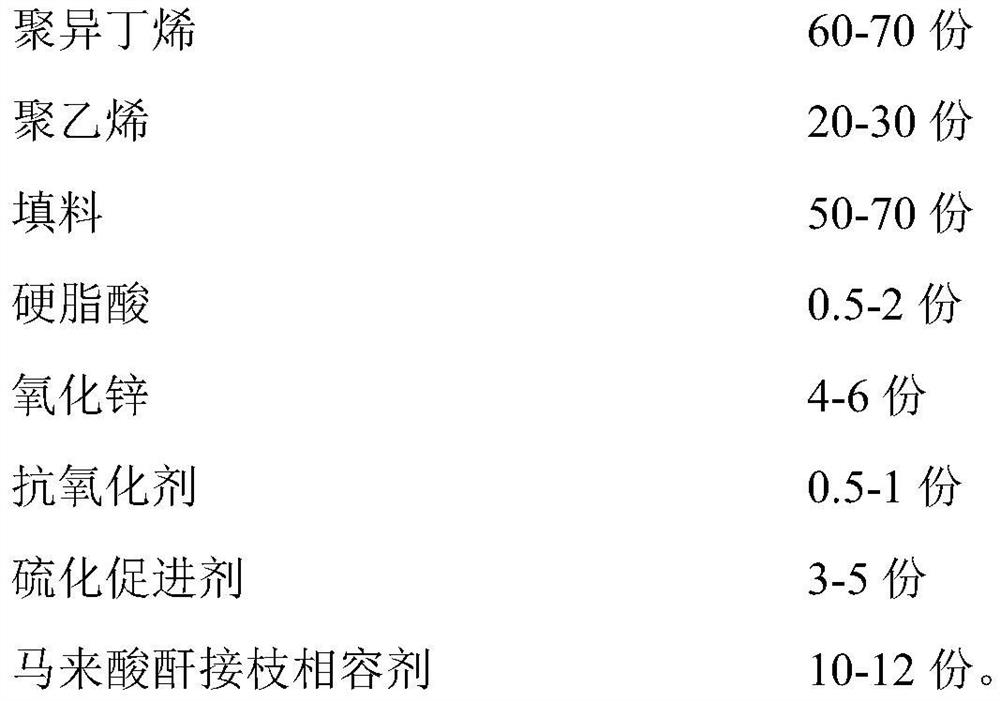

[0031] The self-melting insulating tape with cross-linked polyethylene described in Example 1 consists of the following raw materials in parts by weight:

[0032]

[0033] in:

[0034] The butyl rubber is a copolymer of isobutylene and a small amount of isoprene or butadiene, and its physical parameters are as follows: the appearance is translucent to milky white particles, and the density is 0.91g / cm 3 , the operating temperature is -40℃~+150℃, the hardness is Shore A65, the surface tension is 33mN / m, the minimum rebound temperature is -40℃, and the resilience is 60%.

[0035] Described polyisobutylene is the polymer that adopts pure isobutylene (≥99%) to be the polymer that raw material makes, and its physical parameter is as follows: appearance is colorless soft solid, and density is 0.94g / ml, glass transition temperature is-70 ℃, The specific heat capacity is 1.95kJ / (kg·K), the melting point is 43°C, the brittle temperature limit is -65°C, and the surface tension is 29...

Embodiment 2

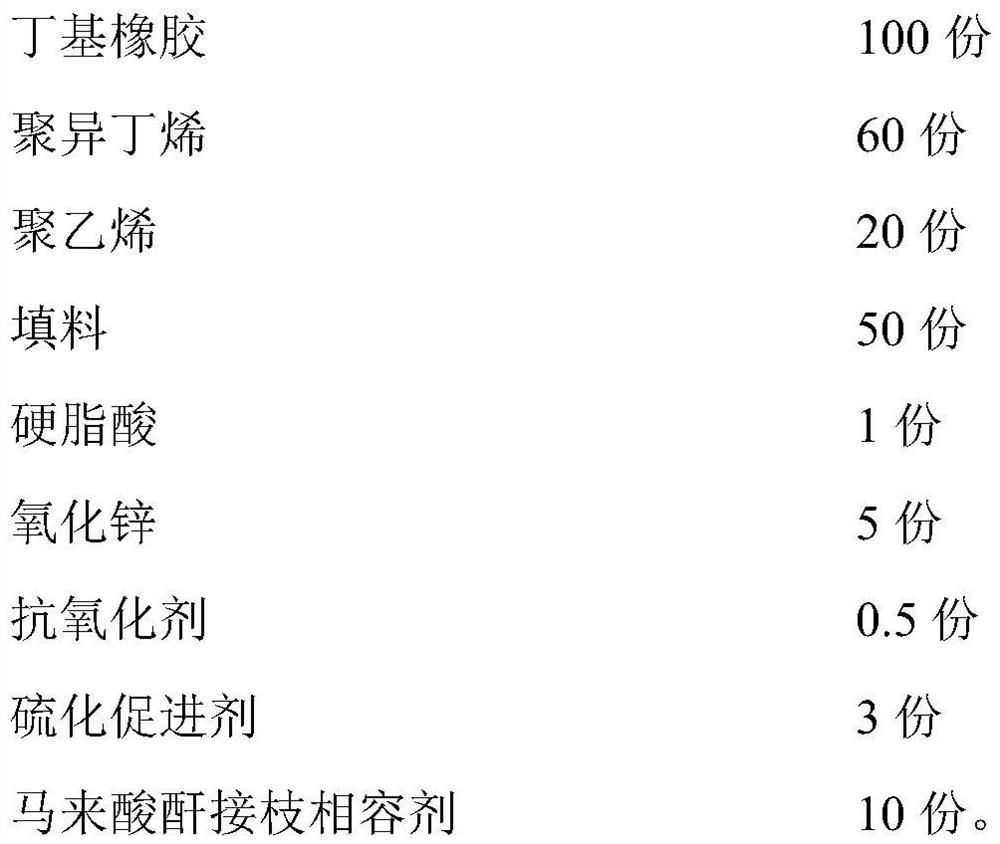

[0048] The self-melting insulating tape with cross-linked polyethylene described in Example 2 is composed of the following raw materials in parts by weight:

[0049]

[0050]

[0051] in:

[0052]The butyl rubber is a copolymer of isobutylene and a small amount of isoprene or butadiene, and its physical parameters are as follows: the appearance is translucent to milky white particles, and the density is 0.91g / cm 3 , the operating temperature is -40℃~+150℃, the hardness is Shore A65, the surface tension is 33mN / m, the minimum rebound temperature is -40℃, and the resilience is 60%.

[0053] Described polyisobutylene is the polymer that adopts pure isobutylene (≥99%) to be the polymer that raw material makes, and its physical parameter is as follows: appearance is colorless soft solid, and density is 0.94g / ml, glass transition temperature is-70 ℃, The specific heat capacity is 1.95kJ / (kg·K), the melting point is 43°C, the brittle temperature limit is -65°C, and the surface...

Embodiment 3

[0063] The self-melting insulating tape with cross-linked polyethylene described in Example 3 consists of the following raw materials in parts by weight:

[0064]

[0065]

[0066] in:

[0067] The butyl rubber is a copolymer of isobutylene and a small amount of isoprene or butadiene, and its physical parameters are as follows: the appearance is translucent to milky white particles, and the density is 0.91g / cm 3 , the operating temperature is -40℃~+150℃, the hardness is Shore A65, the surface tension is 33mN / m, the minimum rebound temperature is -40℃, and the resilience is 60%.

[0068] Described polyisobutylene is the polymer that adopts pure isobutylene (≥99%) to be the polymer that raw material makes, and its physical parameter is as follows: appearance is colorless soft solid, and density is 0.94g / ml, glass transition temperature is-70 ℃, The specific heat capacity is 1.95kJ / (kg·K), the melting point is 43°C, the brittle temperature limit is -65°C, and the surface t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com