Crystal forms of L-glufosinate-ammonium, and preparation method and application thereof

A technology of glufosinate-ammonium and glufosinate-ammonium hydrochloride is applied to the crystal form of L-glufosinate-ammonium and the fields of preparation and application thereof, which can solve the problems of less research on crystal form, insufficient stability, insufficient hygroscopicity, ionization difference and the like , to achieve the effects of good solubility, good pharmacokinetics, and improved levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Embodiment 1: Preparation of the crystal form A of L-glufosinate-ammonium

[0063] Method 1: L-glufosinate-ammonium hydrochloride (100g, 0.46mol) is added in water (200g), feeds ammonia gas and adjusts pH=7, underpressure distillation concentrates to 75%, adds methanol ( 600g), was cooled to 5°C at a cooling rate of Tj-Tr=2K, kept at a temperature of 24 hours, solids were precipitated, filtered, dried, then added to methanol (300g) and refluxed for 24 hours, and cooled at a cooling rate of Tj-Tr=2K The temperature was lowered to 5° C., and the temperature was kept for 24 hours. Solids were precipitated, filtered, and dried to obtain the crystal form A of L-glufosinate-ammonium with an HPLC purity of 99%.

[0064] Method 2: Add L-glufosinate-ammonium hydrochloride (100g, 0.46mol) into water (200g), feed ammonia gas to adjust pH=7, concentrate to 50% by distillation under reduced pressure, cool to 30°C, and Add methanol (600g) at a rate of 2g / min under high temperature, ...

Embodiment 2

[0070] Embodiment 2: Preparation of the crystal form B of L-glufosinate-ammonium

[0071] Add L-glufosinate-ammonium hydrochloride (100g, 0.46mol) into water (200g), feed ammonia gas to adjust pH=7, concentrate to 50% by distillation under reduced pressure, add methanol (600g) at 60°C, The temperature was lowered to 5° C. at a cooling rate of Tj-Tr=2K, and the temperature was kept for 5 days. Solids were precipitated, filtered, and dried to obtain the crystal form B of L-glufosinate-ammonium.

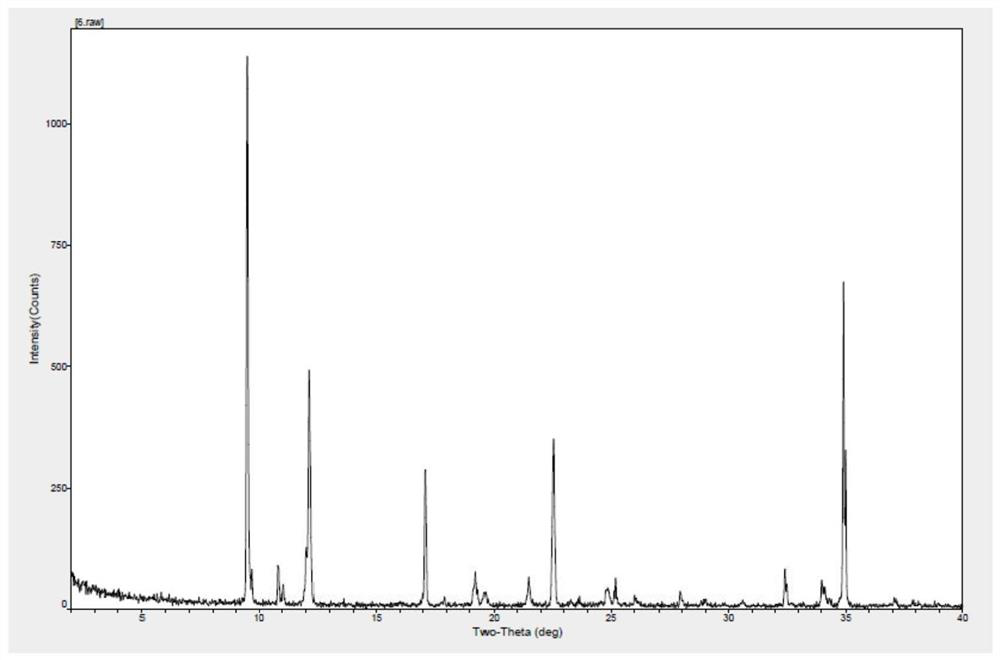

[0072] Carry out XRPD test to the solid of above-mentioned gain, spectrogram is as image 3 As shown, there are characteristic peaks at diffraction angles 2θ=9.484°, 12.163°, 17.098°, 22.540°, and 34.899°, and the 2θ error range is ±0.2 degrees. Its x-ray powder diffraction data are shown in Table 2.

[0073] Table 2: XRPD pattern details of Form B of L-glufosinate-ammonium

[0074]

[0075]

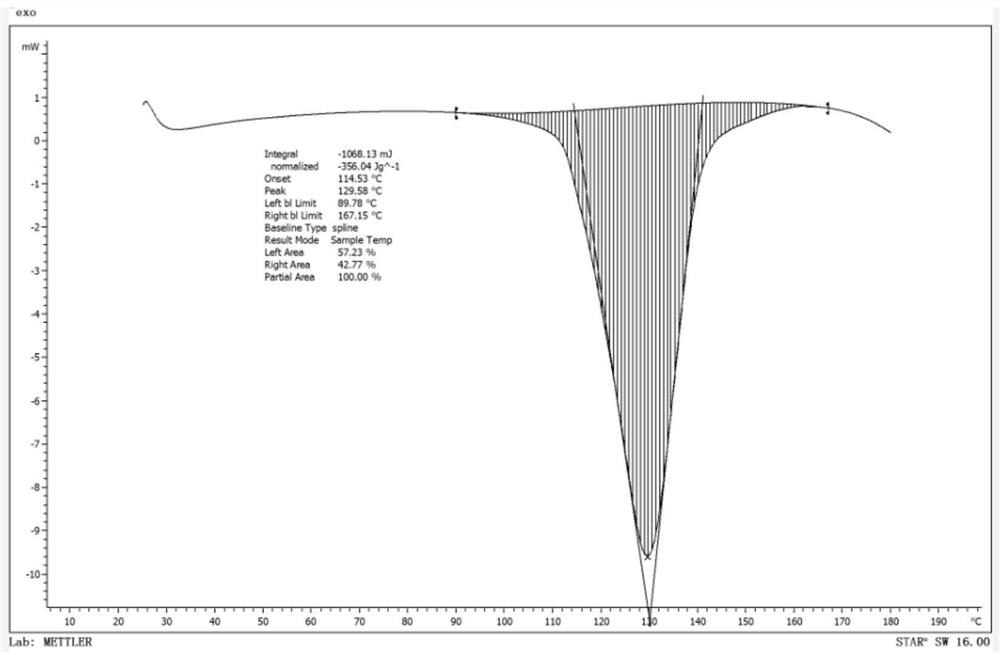

[0076] DSC results ( Figure 4 ) shows that there is an absorption peak at 134.07° C. ...

Embodiment 3

[0077] Embodiment 3: Preparation of the crystal form C of L-glufosinate-ammonium

[0078] Add L-glufosinate-ammonium hydrochloride (100 g, 0.46 mol) into water (200 g), pass through ammonia gas to adjust pH=2.5, concentrate to 50% by distillation under reduced pressure, add methanol (300 g) at 60 ° C, The temperature was lowered to 5° C. at a cooling rate of Tj-Tr=1K, and the temperature was kept for 24 hours. Solids were precipitated, filtered, and dried to obtain the crystal form C of L-glufosinate-ammonium.

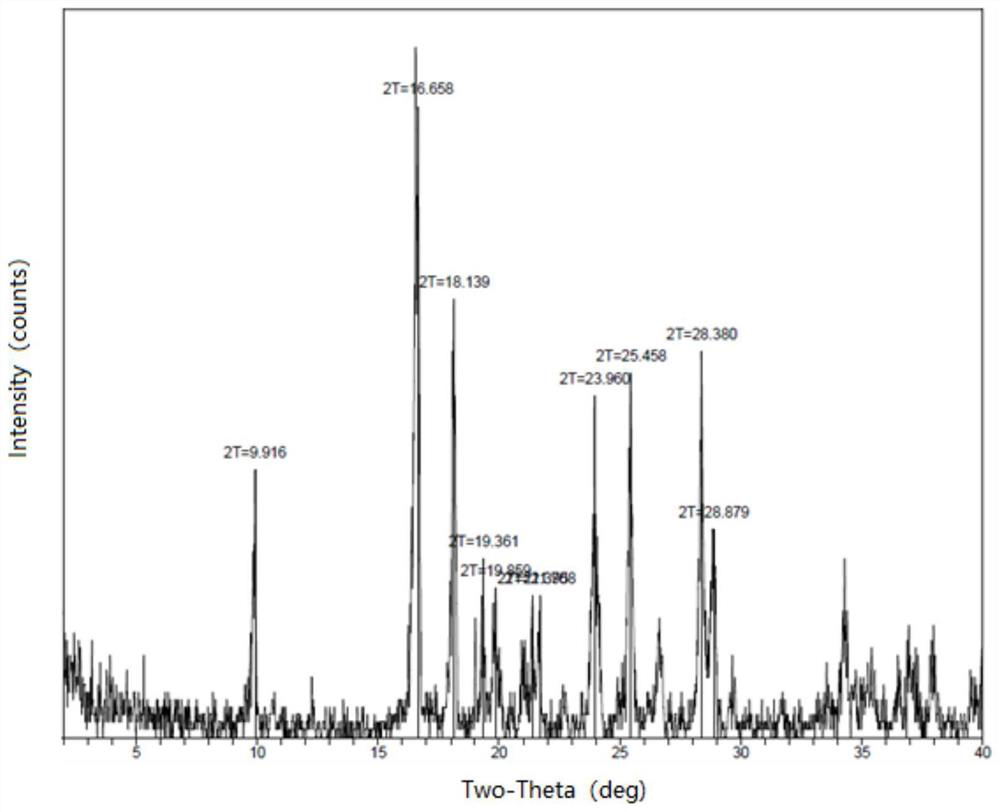

[0079] Carry out XRPD test to the solid of above-mentioned gain, spectrogram is as Figure 5 As shown, there are characteristic peaks at diffraction angles 2θ=16.018°, 19.067°, 19.338°, and 21.581°, and the 2θ error range is ±0.2 degrees. Its x-ray powder diffraction data are shown in Table 3.

[0080] Table 3: XRPD pattern details of Form C of L-glufosinate-ammonium

[0081]

[0082]

[0083] DSC results ( Figure 6 ) shows that there is an absorption peak a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com