Etching solution for removing etching residues of ceramic substrate and etching method

A technology for ceramic substrate and etching solution, which is applied in the field of etching solution for removing etching residues of ceramic substrates, can solve the problems of poor copper surface condition, poor stability, incomplete etching, etc., and achieves good copper surface condition and good electrical properties. , the effect of etching thoroughly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

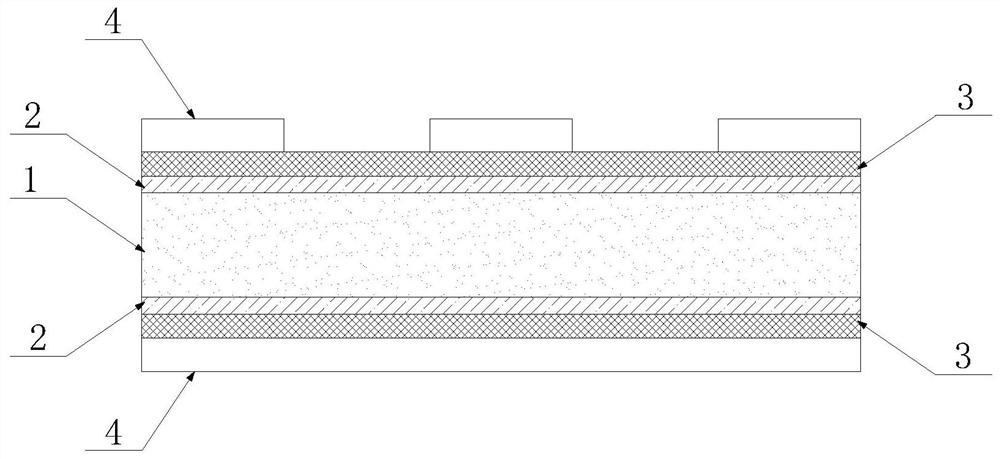

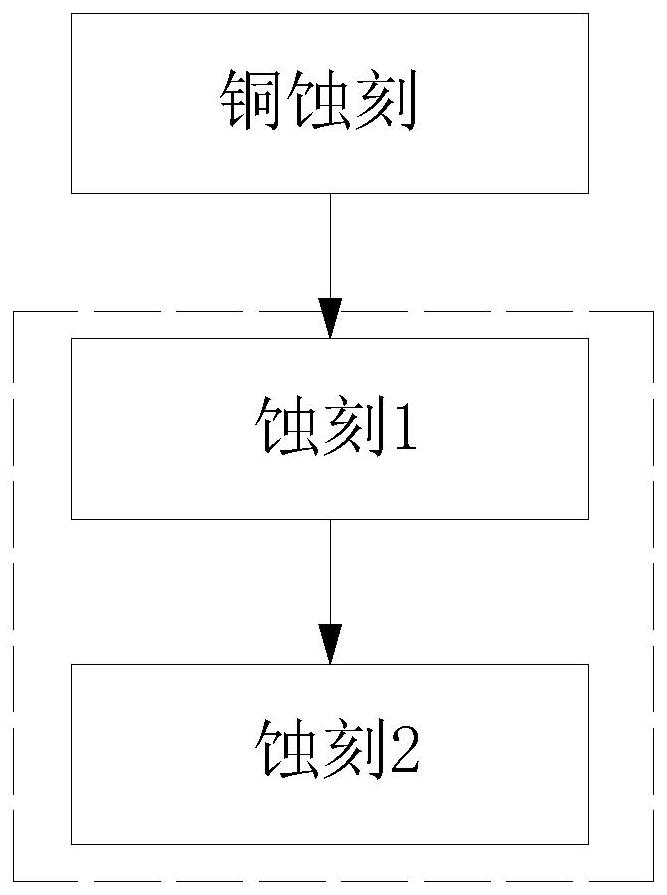

[0030] see Figure 1-2 , the present invention provides the following technical solutions: a ceramic substrate etching residue removal etching solution, the etching solution includes etching solution A and etching solution B, etching solution A and etching solution B contain hydrogen peroxide, ammonia, sulfuric acid, structure Containing one or more compositions of hydroxyl group, carboxyl group and their salts, organic amine and surfactant, the etching solution is used to remove solder residue and bonding layer of copper-clad ceramic substrate after copper etching.

[0031] Specifically, the carboxyl group and its salts contained in the etching solution A are polyaspartic acid, glycine, glutamic acid, aspartic acid, EDTA, alanine, threonine, cysteine, arginine One or more combinations of amino acid, tyrosine, DTPA, HEDTA, maleic acid-acrylic acid copolymer, sodium polyacrylate, tyrosine and other substances containing their functional groups.

[0032] Specifically, the surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com