Composite binder grinding wheel for machining large-size silicon carbide substrate and preparation method of composite binder grinding wheel

A technology of silicon carbide substrate and composite binder, which is applied in the direction of bonding grinding wheels, metal processing equipment, manufacturing tools, etc., to achieve a good homogeneous state, solve processing problems, and have the effect of strong grinding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

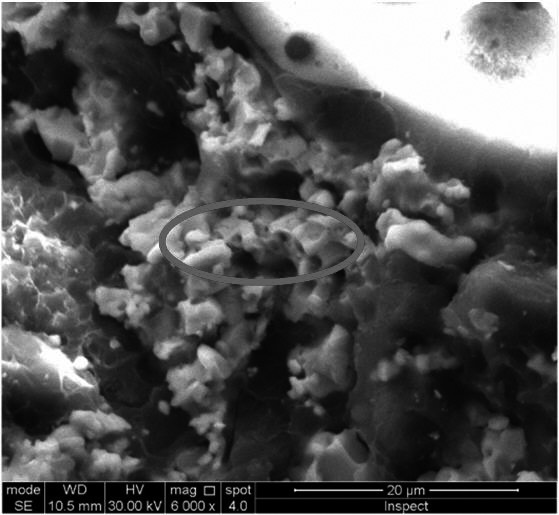

Image

Examples

Embodiment 1

[0032] A composite bond grinding wheel for large-size silicon carbide substrate processing, mainly used for processing large-size silicon carbide substrate materials, the grinding wheel is composed of a base body and a grinding layer, and the raw materials of the grinding layer are calculated by weight percentage. For: particle size 325 / 400, TTI76 diamond abrasive 25%, mixed powder 32%, polyphenylene sulfide 20%, zinc oxide whisker 15%, SG abrasive 8%.

[0033]The mixed powder is obtained through the following process: in terms of mass percentage, 62% of zinc powder, 18.2% of copper powder, 2.2% of aluminum powder, and 6.6% of iron powder are mixed with metal powder, and a high-frequency vibrating screen is used at 2000 times / min Vibrate for 30 minutes, then add 11% graphite, and then put the mixture into a liquid nitrogen cooling wall breaking machine with a rotation speed of 40,000rpm (manufacturer: Domon wall breaking machine model: LM-388, the same below), and the mass rati...

Embodiment 2

[0044] A composite bond grinding wheel for large-size silicon carbide substrate processing, mainly used for processing large-size silicon carbide substrate materials, the grinding wheel is composed of a base body and a grinding layer, and the raw materials of the grinding layer are calculated by weight percentage. For: particle size M34 / 42, TTI77.5 diamond abrasive 45%, mixed powder 25%, polyphenylene sulfide 8%, zinc oxide whisker 12%, SG abrasive 10%.

[0045] The mixed powder is obtained through the following process: in terms of mass percentage, 70% of zinc powder, 15% of copper powder, 0.5% of aluminum powder, and 1.5% of iron powder are used to vibrate at 2000 times / min for 10 min using a high-frequency vibrating sieve, and then Add 13% graphite, then put the mixture into a liquid nitrogen cooling wall breaker with a rotation speed of 20,000rpm, add liquid nitrogen with a mass ratio of 10% of the mixed powder, mix and refine for 2 hours, and obtain a mixture with a partic...

Embodiment 3

[0056] A composite bond grinding wheel for large-size silicon carbide substrate processing, mainly used for processing large-size silicon carbide substrate materials, the grinding wheel is composed of a base body and a grinding layer, and the raw materials of the grinding layer are calculated by weight percentage. For: particle size 270 / 325, TTI75.8 diamond abrasive 30%, mixed powder 40%, polyphenylene sulfide 10%, zinc oxide whisker 8%, SG abrasive 12%.

[0057] The mixed powder is obtained through the following process: in terms of mass percentage, 65% of zinc powder, 18% of copper powder, 2% of aluminum powder, and 6% of iron powder are used to vibrate at 2000 times / min for 15min by using a high-frequency vibrating sieve, and then Add 9% graphite, then put the mixture into a liquid nitrogen cooling wall breaker with a rotation speed of 30,000rpm, add liquid nitrogen with a mass ratio of 10% of the mixed powder, mix and refine for 5 hours, and obtain a mixture with a particle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com