An organic porous framework material with adsorption and desulfurization performance and its preparation method

A porous skeleton, adsorption desulfurization technology, applied in chemical instruments and methods, refined hydrocarbon oil, inorganic chemistry, etc., can solve problems such as intolerance to strong acid and strong alkali, difficult regeneration, poor thermal stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Step 1: Add 2mol of 1,3,5-benzenetricarbaldehyde and 3mol of 1,4-benzenediacetonitrile into the reactor, then add 1L of 1,4-dioxane and 1L of 1,3, 5 Trimethylbenzene solvent, after stirring evenly, add 0.2L of 6mol / L DBU (1,8-diazabicyclo[5.4.0]undec-7-ene) solution as a catalyst, and react at 150°C for 72h to obtain a mixed liquid;

[0047] Step 2: Cool the mixture obtained in Step 1 to room temperature, and pour it into the material barrel, during which time the residue in the kettle can be washed with deionized water. The obtained mixture was subjected to suction filtration, and deionized water and methanol were used as washing solvents, each washing three times to obtain a filter cake. Put the filter cake into a beaker filled with DMF solution, rotate and stir on a magnetic stirrer for 1 h, and then carry out suction filtration. The obtained product was subjected to Soxhlet extraction with methanol reagent for 24 hours to further remove impurities, and the Soxhlet...

Embodiment 2

[0053] Step 1: Add 2mol monomer 1,3,5-benzenetricarbaldehyde and 3mol 1,4-benzenediacetonitrile into the reaction kettle, then add 2L of N,N-dimethylformamide solvent, stir well Add 0.2L of 6mol / L sodium hydroxide solution as a catalyst, and react at 100°C for 72h to obtain a mixed solution;

[0054] Step 2: Cool the mixture obtained in Step 1 to room temperature, and pour it into the material barrel, during which time the residue in the kettle can be washed with deionized water. The obtained mixture was subjected to suction filtration, and deionized water and methanol were used as washing solvents, each washing three times to obtain a filter cake. Put the filter cake into a beaker filled with DMF solution, rotate and stir on a magnetic stirrer for 1 h, and then carry out suction filtration. The obtained product was subjected to Soxhlet extraction with methanol reagent for 24 hours to further remove impurities, and the Soxhlet-extracted solid was vacuum-dried at 100° C. for 1...

Embodiment 3

[0064] Step 1: Add 2mol of monomer 1,3,5-benzenetricarbaldehyde and 3mol of 1,4-benzenediacetonitrile into the reaction kettle, then add 2L of dichlorobenzene solvent, stir well and add 0.2L of 6mol / L of potassium carbonate solution was used as a catalyst, and reacted at 120°C for 72 hours to obtain a mixed solution;

[0065] Step 2: Cool the mixture obtained in Step 1 to room temperature, and pour it into the material barrel, during which time the residue in the kettle can be washed with deionized water. The obtained mixture was subjected to suction filtration, and deionized water and methanol were used as washing solvents, each washing three times to obtain a filter cake. Put the filter cake into a beaker filled with DMF solution, rotate and stir on a magnetic stirrer for 1 h, and then carry out suction filtration. The obtained product was subjected to Soxhlet extraction with methanol reagent for 24 hours to further remove impurities, and the Soxhlet-extracted solid was va...

PUM

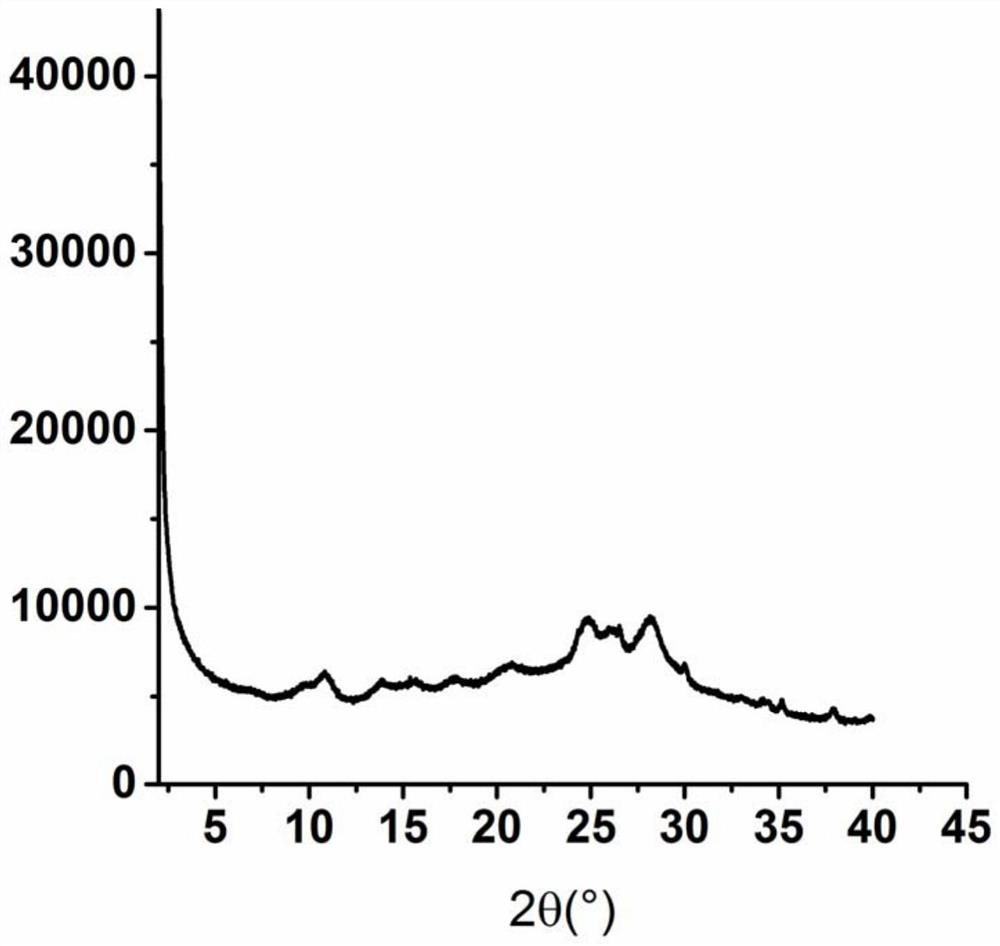

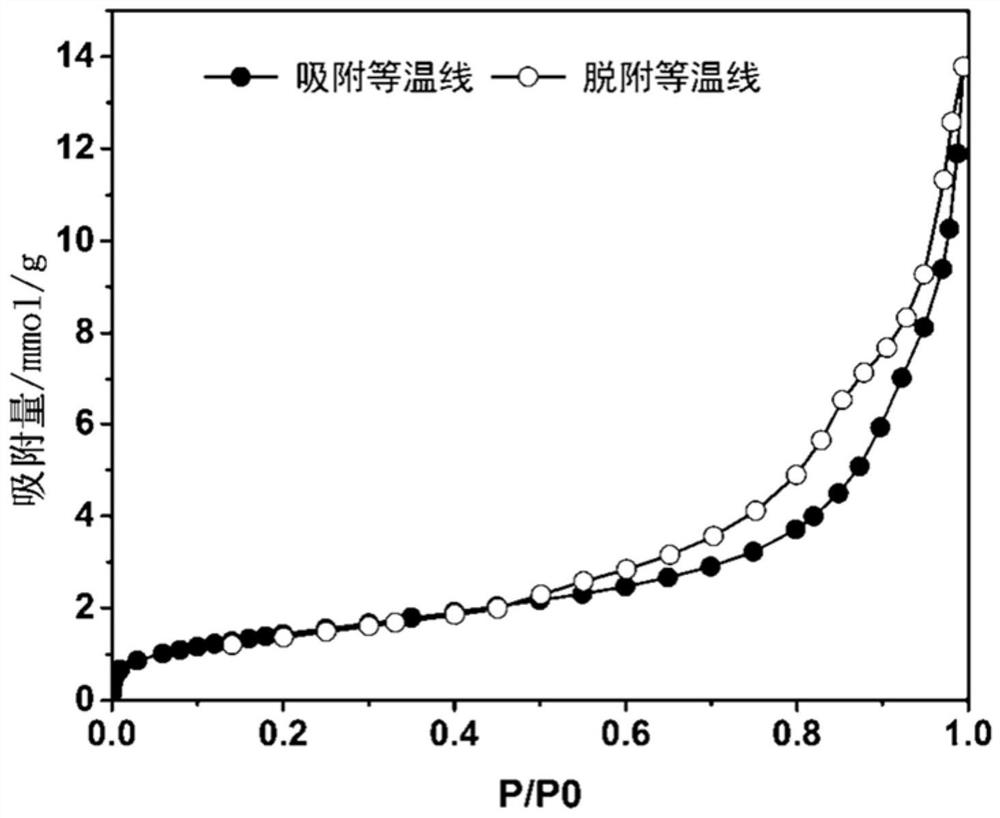

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com