Silylated isocyanurate compound, metal anticorrosive agent, curable silicone resin composition, and semiconductor device

A technology of silylated isocyanurate and anti-corrosion agent, which is applied in the field of silylated isocyanurate compounds, can solve the problems of resin heat resistance decline, etc., and achieve excellent vulcanization resistance and long-term color development good performance and ensure long-term reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

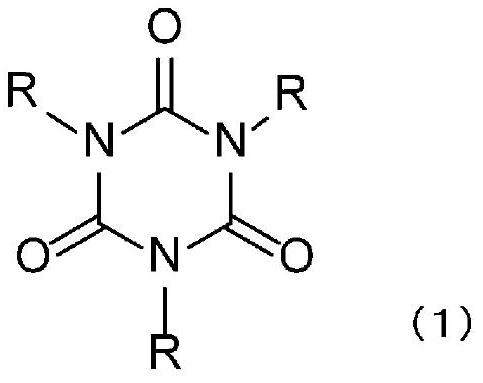

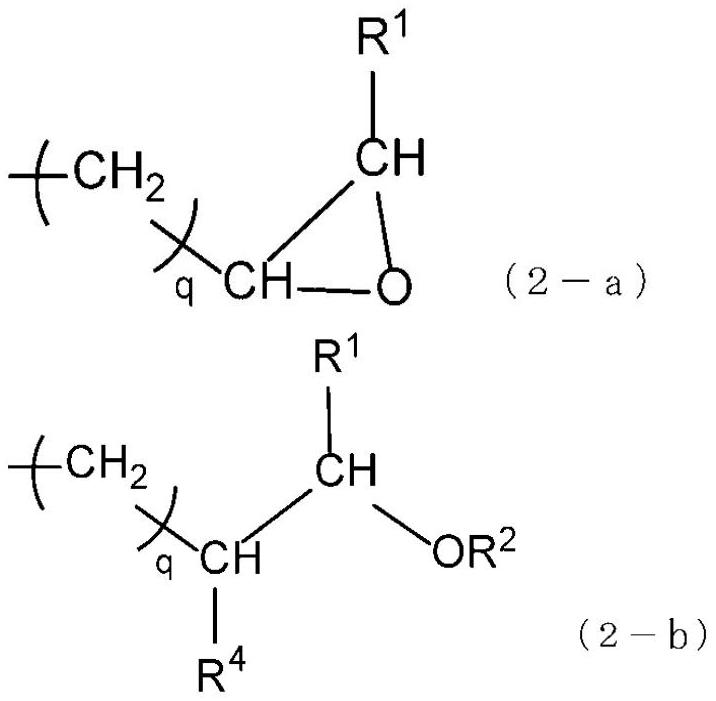

[0082] [Preparation method of silylated modified isocyanurate compound]

[0083] The silylated modified isocyanurate compound of the present invention can be produced, for example, by subjecting triglycidyl isocyanurate to a hydrolysis reaction with chlorosilane and alkoxysilane. The conditions of the hydrolysis reaction only need to be properly adjusted. For example, the reaction ratio of epoxy group to trimethylchlorosilane is 1:1 in molar ratio.

[0084] [anticorrosion agent]

[0085] The silylated isocyanurate compound of the present invention can exhibit an excellent effect as a metal corrosion inhibitor. Therefore, it is preferable to prepare a metal anticorrosion agent containing the silylated isocyanurate compound of the present invention.

[0086] When the silylated isocyanurate compound of the present invention is used as a corrosion inhibitor, it may be added in an amount of 0.001 to 5% by mass, preferably 0.01 to 3% by mass based on the resin composition. The c...

Synthetic example

[0212] 297.3 g (1.0 mol) of triglycidyl isocyanurate was added to the reaction vessel, and dissolved in 350 g of toluene. 217.3 g (2.0 mol) of trimethylchlorosilane was added thereto, and the temperature was raised to 80°C. 18 g (1.0 mol) of water was added dropwise thereto over 30 minutes. After completion of the dropwise addition, the mixture was further heated and stirred at 80° C. for 3 hours. In addition, tris(pentafluorophenyl)borane was added as a reaction catalyst to carry out a chemical reaction.

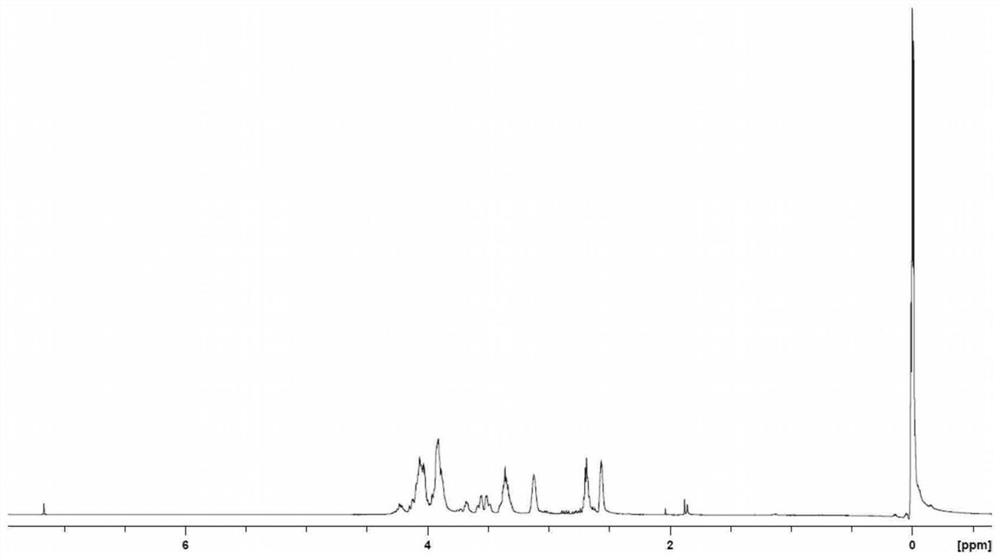

[0213] After completion|finish of heating, it cooled to room temperature (25 degreeC), and it washed with water using 10 mass % sodium sulfate aqueous solution. Then, 50 g of magnesium-aluminum solid solution (trade name: KW-2200, manufactured by Kyowa Chemical Industry Co., Ltd.) was added, and stirred at 25° C. for 1 hour to remove tris(pentafluorophenyl)borane by adsorption. KW-2200 was removed by pressure filtration, and the residual solvent was distilled off under r...

Embodiment 2

[0269] Add the following ingredients and stir thoroughly to prepare a curable silicone resin composition:

[0270] (A1) Composition: 75mol% PhSiO 3 / 2 unit, 25mol% ViPhMeSiO 1 / 2 Branched-chain phenylmethylpolysiloxane composed of units (Mw=2,500, the amount of hydroxyl groups bonded to silicon atoms is 0.04 mol / 100g, and the amount of alkoxy groups bonded to silicon atoms is 0.06 mol / 100g) , which is 30 copies;

[0271] Component (B): An organohydrogenpolysiloxane represented by the following formula (6), in which the total number of hydrogen atoms bonded to silicon atoms in the component (B) is relative to the components (A) and (D) The ratio of the total number of silicon atom-bonded vinyl groups (hereinafter, sometimes expressed as SiH / SiVi ratio) is the amount of 1.0;

[0272] (C) Component: 0.01 part of octanol-modified solution of chloroplatinic acid (platinum element content: 1% by mass); and

[0273] (D) Component: following formula (7), it is 0.05 part.

[0274] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com