Membrane concentration process for pulullan

A pullulan polysaccharide and membrane concentration technology, which is applied in the field of pullulan polysaccharide membrane concentration process, can solve the problems of difficult to guarantee product quality, high energy consumption for thermal concentration, large loss of sugar components, etc. The effect of improving the yield of resources and products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

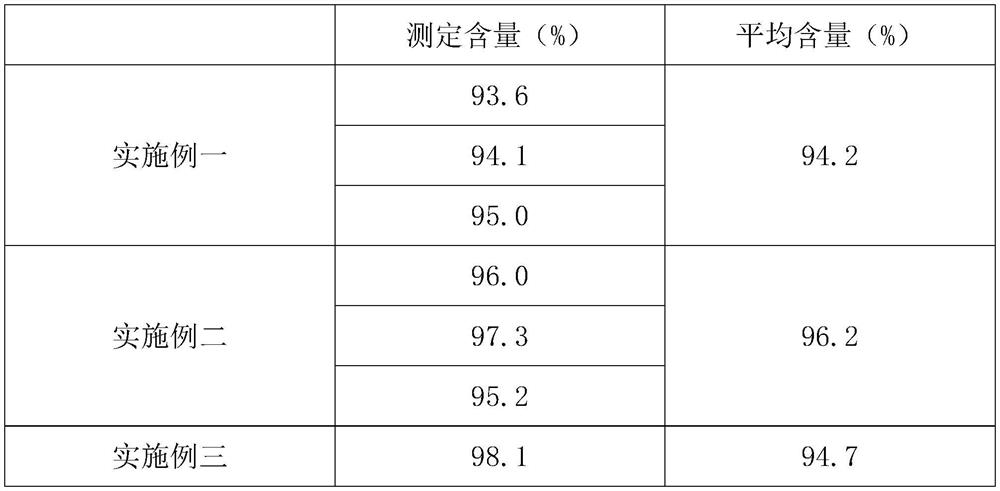

Embodiment 1

[0028] The present invention provides a technical solution: a conventional condensed process, which includes the following steps:

[0029] S1, pretreatment: Import the fermentation liquid containing Procolate and more impurities into a pretreatment tank, high temperature resection;

[0030] S2, clarified: add an appropriate amount of filter fillers to the fermentation broth, introduced into the plate frame filter press to extract the clear liquid;

[0031] S3, decolorization: Import the clarified liquid into the tank to decolorize;

[0032] S4, removal of protein: Import the decolorized clear liquid into the treatment tank, remove the impurity protein by resin adsorption method to obtain a treatment liquid;

[0033] S5, ultrafiltration processing: Import the processing liquid into the ultrafiltration membrane system, circulating filtration, can remove 60-90% protein, 99% monosaccharide and disaccharide, ash, etc. by ultrafiltration concentration. purity;

[0034] S6, drying: The u...

Embodiment 2

[0044] The difference from the embodiment is that the high temperature interferase treatment temperature in the step S1 is 80 ° C, the treatment time is 1.5 h;

[0045] The quality of the filtration in the step S2 is 2% of the total mass of the fermentation broth;

[0046] The mass of the activated carbon accounts for 0.5% of the total mass of the clear liquid, and the decolorization treatment temperature is 50 ° C, the stirring treatment time is 60 min;

[0047] The step S3 also includes a hydrogen peroxide treatment after activated carbon, and includes the step of adding a hydrogen peroxide solution to a solution of the activated carbon and a hydrogen peroxide solution, from 0.3% of the total mass of the solution;

[0048] The ultrafiltration process in the step S5 employs a roll ultrafiltration membrane having a molecular weight of 5,000 Daltons, a super filtered treatment pressure of 7 bar, a temperature of 25 ° C;

[0049] The cyclic filtration in the step S5 includes the ste...

Embodiment 3

[0051] The difference from the embodiment is that the high-temperature resembutment treatment temperature in the step S1 is 90 ° C, and the treatment time is 1 h;

[0052] The quality of the filtration in the step S2 accounts for 3% of the total mass of the fermentation broth;

[0053] The quality of the activated carbon accounts for 1% of the total mass of the clear liquid, the decolorization treatment temperature is 80 ° C, and the stirring treatment time is 20 min;

[0054] The step S3 also includes a hydrogen peroxide treatment after active carbon, and includes a hydrogen peroxide solution, and the mass of the hydrogen peroxide solution comprises 0.5% by mass of the hydrogen peroxide solution in a solution treated with activated carbon.

[0055] The ultrafiltration process in the step S5 employs a roll ultrafiltration membrane having a molecular weight of 100,000 Daltons, an ultrafiltration pressure of 10bar, and a temperature of 40 ° C;

[0056] The cyclic filtration in the st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com