Method for preparing high-nickel type ternary precursor through ferronickel production conversion and application of method

A precursor and high-nickel technology, applied in the field of metallurgy, can solve problems such as high cost, cumbersome steps, and high sales pressure, and achieve the effect of improving quality, cumbersome steps, and relieving supply pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

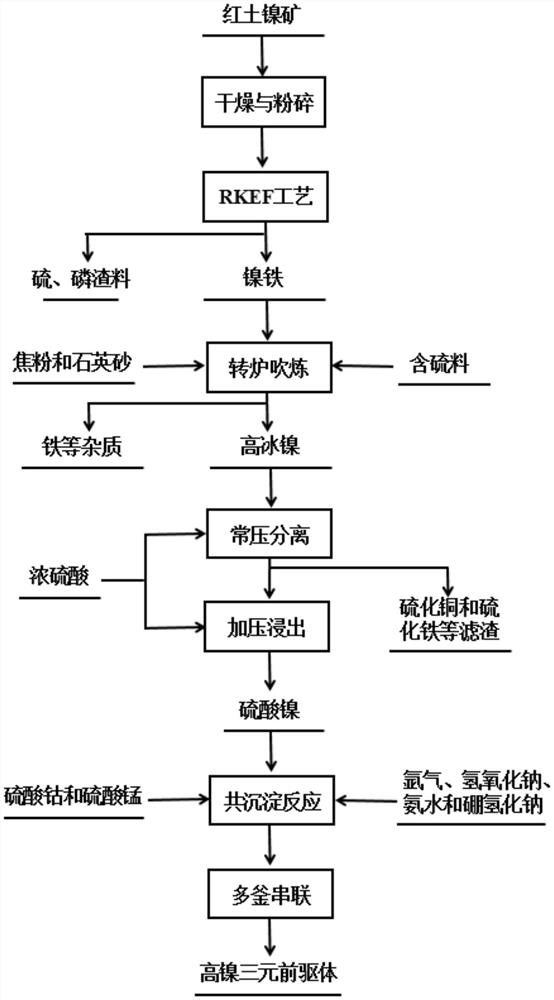

[0060] The method for preparing a high-nickel type ternary precursor by converting ferronickel production in this embodiment includes the following specific steps:

[0061] (1) With nickel content of 1.5%, Fe content of 15%, SiO 2 A high-silicon magnesia laterite nickel ore in Indonesia with a content of 39%, a MgO content of 21% and a water content greater than 30% was used as a raw material. The laterite nickel ore was dried at 800°C to reduce the surface water content to 20%. %, and use a pulverizer to crush it into lump ore with a diameter of 50-100mm;

[0062] (2) Put the crushed lateritic nickel ore and coal in a rotary furnace, conduct a pre-reduction reaction for 2 hours at 1000°C, and remove part of the free water in the ore, and prepare part of the ferronickel by preheating The charge saves the energy consumption of the electric furnace in the next step;

[0063] (3) Transfer the product obtained in the rotary furnace to the feeding bin of the electric furnace, and...

Embodiment 2

[0075] The method for preparing a high-nickel type ternary precursor by converting ferronickel production in this embodiment includes the following specific steps:

[0076] (1) With nickel content of 1.5%, Fe content of 15%, SiO 2 A high-silicon magnesia laterite nickel ore in Indonesia with a content of 39%, a MgO content of 21% and a water content greater than 30% was used as a raw material. The laterite nickel ore was dried at 700°C to reduce the surface water content to 20%. %, and use a pulverizer to crush it into lump ore with a diameter of 50-100mm;

[0077] (2) Put the crushed lateritic nickel ore in a rotary furnace, conduct a pre-reduction reaction at 900°C for 2 hours, and remove part of the free water in the ore. While producing part of ferronickel, save by preheating the charge The energy consumption of the electric furnace in the next step;

[0078] (3) Transfer the product obtained in the rotary furnace to the feeding bin of the electric furnace, and carry out...

Embodiment 3

[0088] The method for preparing a high-nickel type ternary precursor by converting ferronickel production in this embodiment includes the following specific steps:

[0089] (1) With nickel content of 1.5%, Fe content of 15%, SiO 2 A high-silicon magnesia laterite nickel ore in Indonesia with a content of 39%, a MgO content of 21% and a water content greater than 30% was used as a raw material. The laterite nickel ore was dried at 800°C to reduce the surface water content to 20%. %, and use a pulverizer to crush it into lump ore with a diameter of 50-100mm;

[0090] (2) Put the crushed laterite nickel ore in a rotary furnace, conduct a pre-reduction reaction at 1000°C for 2 hours, and remove part of the free water in the ore. The energy consumption of the electric furnace in the next step;

[0091] (3) Transfer the product obtained in the rotary furnace to the feeding bin of the electric furnace, and carry out 2h deep reduction smelting at 1600°C, the reducing atmosphere is C...

PUM

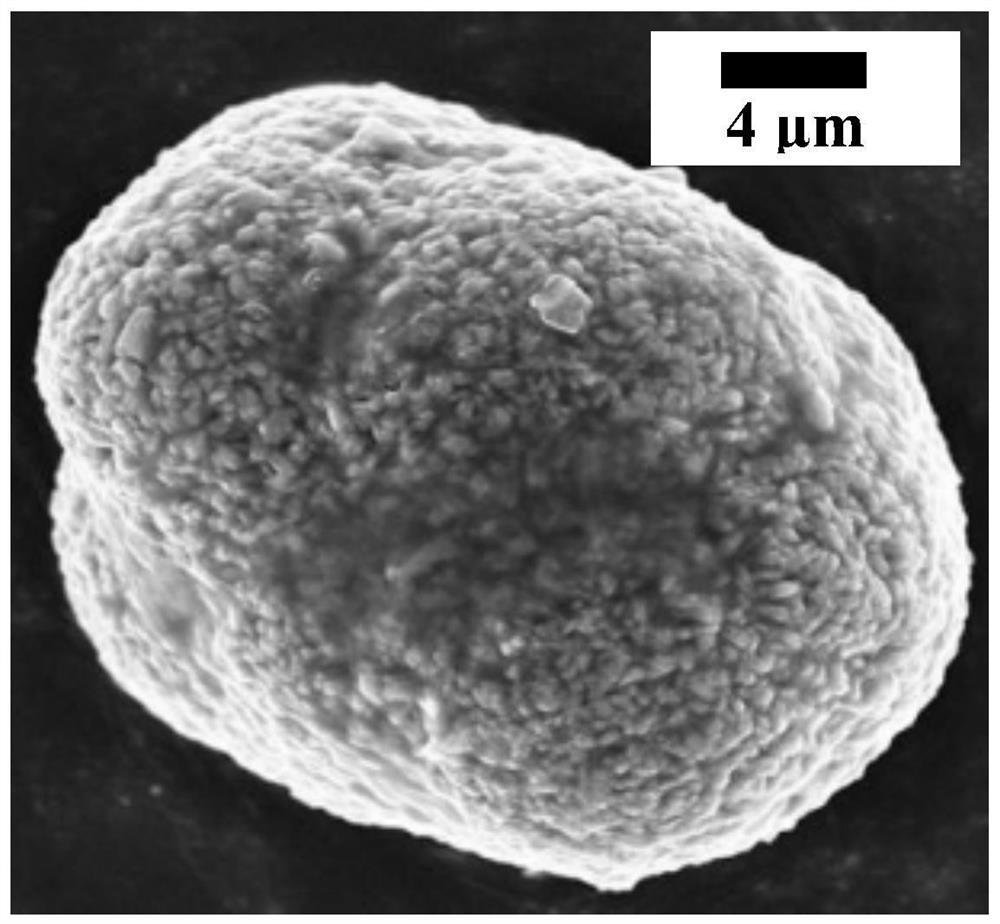

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com