A kind of method for preparing β-haloether and β-halohydrin catalyzed by peroxidase

A technology of peroxidase and peroxidase is applied in the biological field to achieve the effects of being beneficial to large-scale production, simple raw materials and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

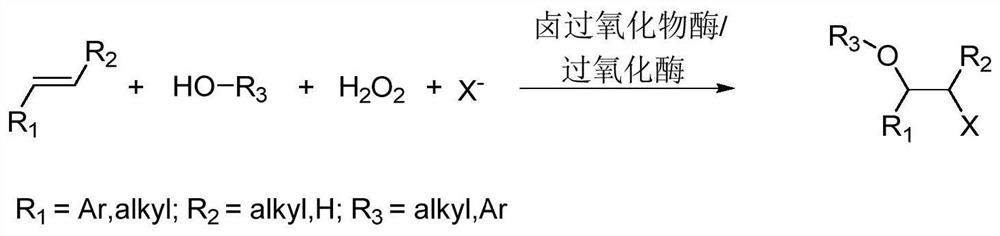

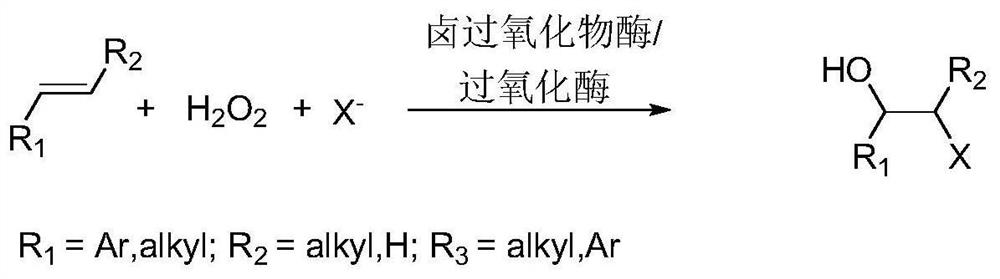

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0082] The preparation method of UPO enzyme in the following examples is as follows:

[0083] Pichia pastoris cell cultures containing rAaeUPO were clarified by centrifugation at 8000 rpm for 2 hours at 4°C. The supernatant was filtered through a 20 μm filter and kept at -80°C. rAaeUPO activity was determined by using the ABTS assay in NaPi buffer pH 5.0;

[0084] Protein purification: The supernatant was concentrated and dialyzed against 100 mM sodium phosphate, pH 7. AaeUPO was purified in one step using an NGC chromatography system (Biorad). Separations were performed on Q Sepharose FF 30-mL cartridges at a flow rate of 5 mL / min. After 90 mL, the retained protein was eluted with a 0-50% NaCl gradient in 450 mL, followed by a 50-100% gradient in 50 mL and 100% NaCl in 75 mL peroxidase activity followed by peroxidase activity in H 2 O 2 In the presence of ABTS oxidation, the appropriate fractions were pooled, concentrated and dialyzed against 100 mM sodium phosphate buff...

Embodiment 1

[0085] Embodiment 1, the preparation of compound 1-bromo-2-ethoxycyclohexane:

[0086]

[0087] In a 100mL reaction flask, add 31.5mL of pH=6 phosphate buffer solution (100 mM sodium dihydrogen phosphate), add absolute ethanol (13.5mL) to the above buffer solution, and then add 0.93mL of phosphate buffer solution with a mass fraction of 30 % hydrogen peroxide solution (concentration is 5.38mol / L, the concentration in the reaction system is 100mM), 0.59g potassium bromide and 0.820g cyclohexene, finally add 150μL VCPO enzyme (the raw material enzyme concentration is 13.5mg / mL, the reaction The enzyme concentration in the system was 500 nM). After about 3 hours of reaction, add 0.59g potassium bromide, 0.93mL hydrogen peroxide (concentration is 5.38mol / L, the concentration in the reaction system is 100mM) and 0.820g cyclohexene, and add three times in total. Add in separate batches to ensure maximum catalytic activity of the enzyme.

[0088] The above reaction system was st...

Embodiment 2

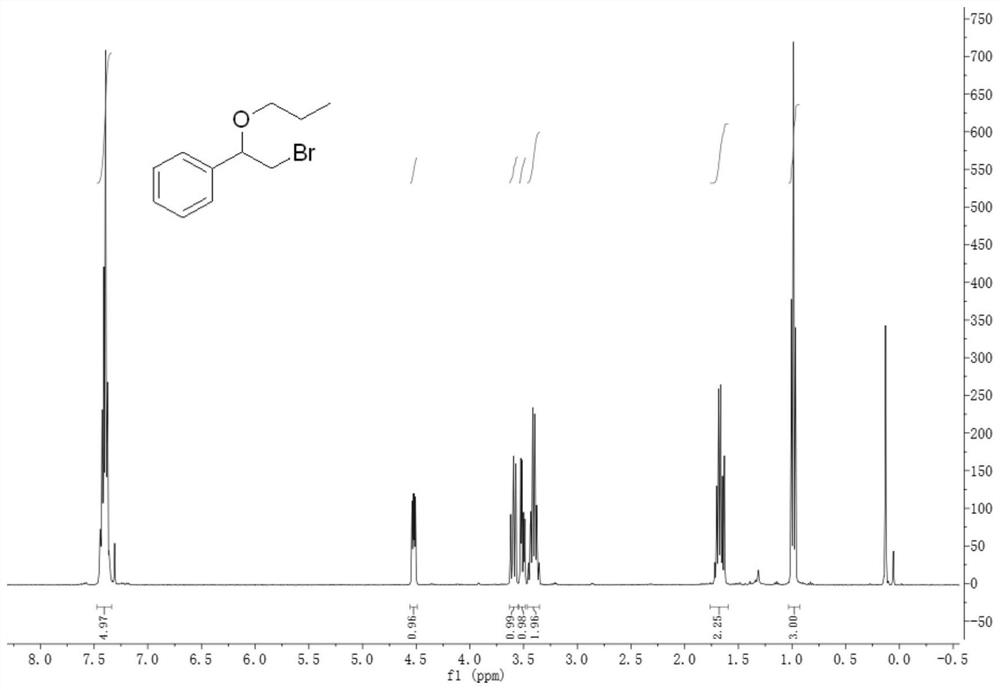

[0089] Embodiment 2, the preparation of compound (2-bromo-1-propoxyethyl) benzene:

[0090]

[0091]In a 100mL reaction flask, add 31.5mL of phosphate buffer solution (same pH=6 as above), then add 13.5mL of absolute ethanol to dissolve in the buffer solution, and then add 0.93mL of 30% hydrogen peroxide solution in sequence (the concentration is 5.38mol / L, the concentration in the reaction system is 100mM), 0.59g potassium bromide and 0.16g styrene, and finally 150 μL VCPO enzyme (the same as the above enzyme concentration is 13.5mg / mL, the enzyme concentration in the reaction system is 500nM). After about 3 hours of reaction, 0.59 g of potassium bromide, 0.93 mL of hydrogen peroxide (concentration of 5.38 mol / L) and 0.16 g of styrene were added three times in total.

[0092] The above reaction system was stirred in a water bath at 30°C for 9 hours, then the reaction was terminated, 100 mL of ethyl acetate was added for extraction twice, the organic phases were combined, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com