Method for recovering silver and rhenium from waste ethylene oxide catalyst

A technology of waste ethylene oxide catalyst and ethylene oxide catalyst, which is applied in the direction of improving process efficiency, can solve problems such as damaged packages and complicated methods, and achieves the effects of reducing pollution, improving leaching rate and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

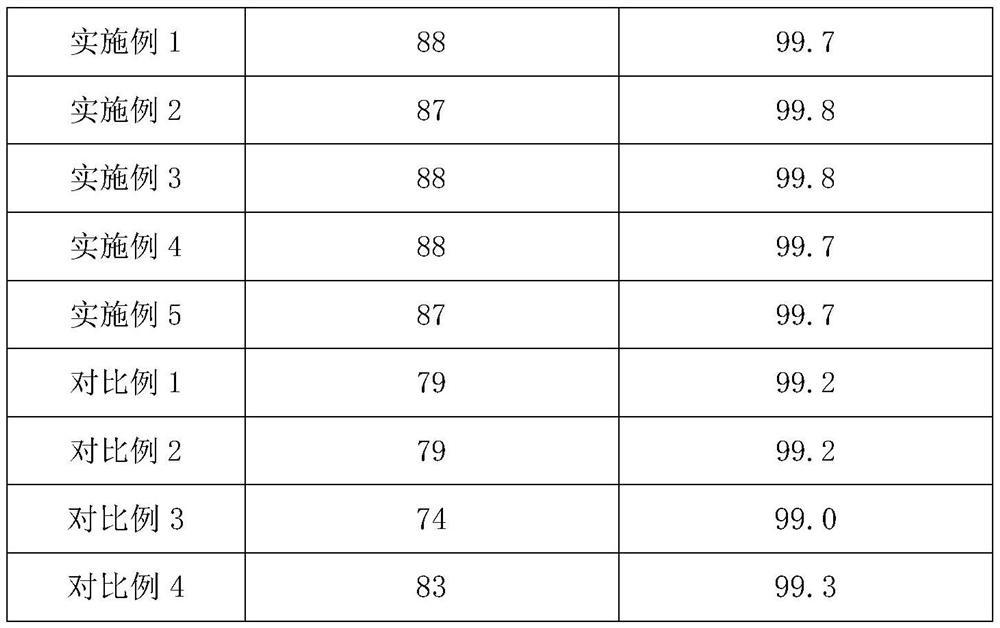

Examples

Embodiment 1

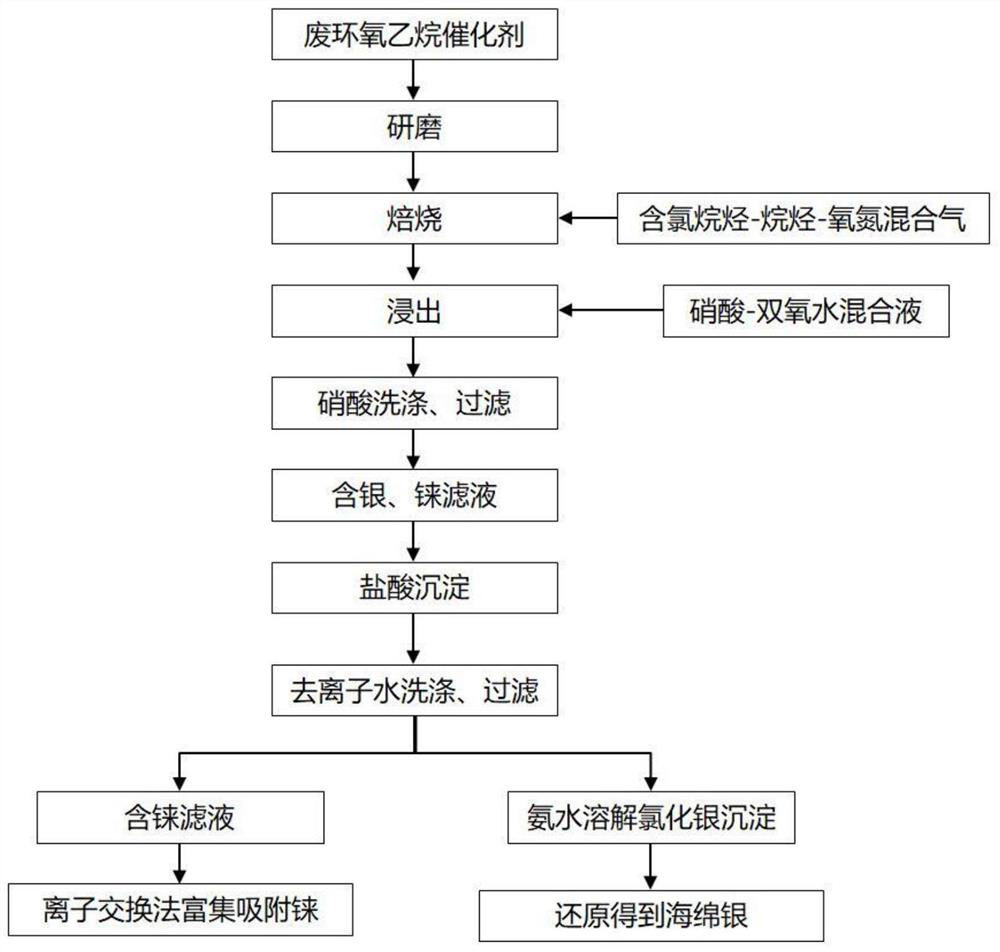

[0044] Silver and rhenium are recovered from spent ethylene oxide catalysts, comprising the following steps:

[0045] (1) Grinding: Grinding the waste ethylene oxide catalyst into 100 mesh particles;

[0046] (2) Roasting: the particles obtained in step (1) are placed in a tube furnace, and a mixture of 8vol.% monochloromethane, 10vol.% methane, 2vol.% oxygen and 80vol.% nitrogen is introduced into the furnace. Gas, heating tube furnace to 220°C, roasting for 20h;

[0047] (3) Leaching: Put the waste ethylene oxide silver catalyst roasted in step (2) in the reactor, add nitric acid with a mass fraction of 15% and hydrogen peroxide with a mass fraction of 5% according to the volume ratio of 1:0.2 The mixed solution formed, and the solid-to-liquid ratio of the waste ethylene oxide silver catalyst in the reactor to the mixed solution was 1g: 3mL, heated the reactor to 70°C, and leached for 3 hours;

[0048] (4) Filtration, washing: after step (3) leaching finishes, filter, obta...

Embodiment 2

[0055] Silver and rhenium are recovered from spent ethylene oxide catalysts, comprising the following steps:

[0056] (1) grinding: the waste ethylene oxide catalyst is ground into 300 mesh particles;

[0057] (2) Roasting: the particles obtained in step (1) are placed in a tube furnace, and a mixture of 15vol.% monochlorethylene, 12vol.% propane, 5vol.% oxygen and 68vol.% nitrogen is introduced. Gas, heating tube furnace to 600°C, roasting for 60h;

[0058] (3) Leaching: Put the waste ethylene oxide silver catalyst roasted in step (2) in the reactor, add nitric acid with a mass fraction of 30% and hydrogen peroxide with a mass fraction of 10% according to the volume ratio of 1:0.5 The mixed solution formed, and the solid-to-liquid ratio of the waste ethylene oxide silver catalyst to the mixed solution in the reactor was 1g: 4mL, heated the reactor to 90°C, and leached for 5h;

[0059] (4) Filtration, washing: after step (3) leaching finishes, filter, obtain filtrate and fil...

Embodiment 3

[0065] Silver and rhenium are recovered from spent ethylene oxide catalysts, comprising the following steps:

[0066] (1) Grinding: Grinding the waste ethylene oxide catalyst into 100 mesh particles;

[0067] (2) roasting: the particles obtained in step (1) are placed in a tube furnace, and the mixed gas of methane and ethane (wherein the volume ratio of methane and ethane is 1:1), 3vol.% oxygen and 71vol.% nitrogen mixed gas, heating tube furnace to 500 ° C, roasting 55h;

[0068] (3) Leaching: the waste ethylene oxide silver catalyst after the step (2) roasting is placed in the reactor, adding nitric acid and 10% hydrogen peroxide by mass fraction is 1: 0.5 according to the volume ratio The mixed solution formed, and the solid-to-liquid ratio of the waste ethylene oxide silver catalyst in the reactor to the mixed solution was 1g: 4mL, heated the reactor to 80°C, and leached for 5h;

[0069] (4) Filtration, washing: after step (3) leaching finishes, filter, obtain filtrate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com