Nanometer material-loaded aramid fiber-coated battery diaphragm, preparation method thereof, and lithium-sulfur battery

A technology of nanomaterials and battery separators, applied in the direction of lithium batteries, battery pack components, non-aqueous electrolyte batteries, etc., can solve the problems of hindering the migration path of lithium ions, slow migration of lithium ions, and easy peeling of coatings, etc., to achieve excellent heat dissipation Stability and chemical stability, excellent adhesion, effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The preparation method of the aramid-coated battery diaphragm loaded with nanomaterials of the present invention comprises the following steps:

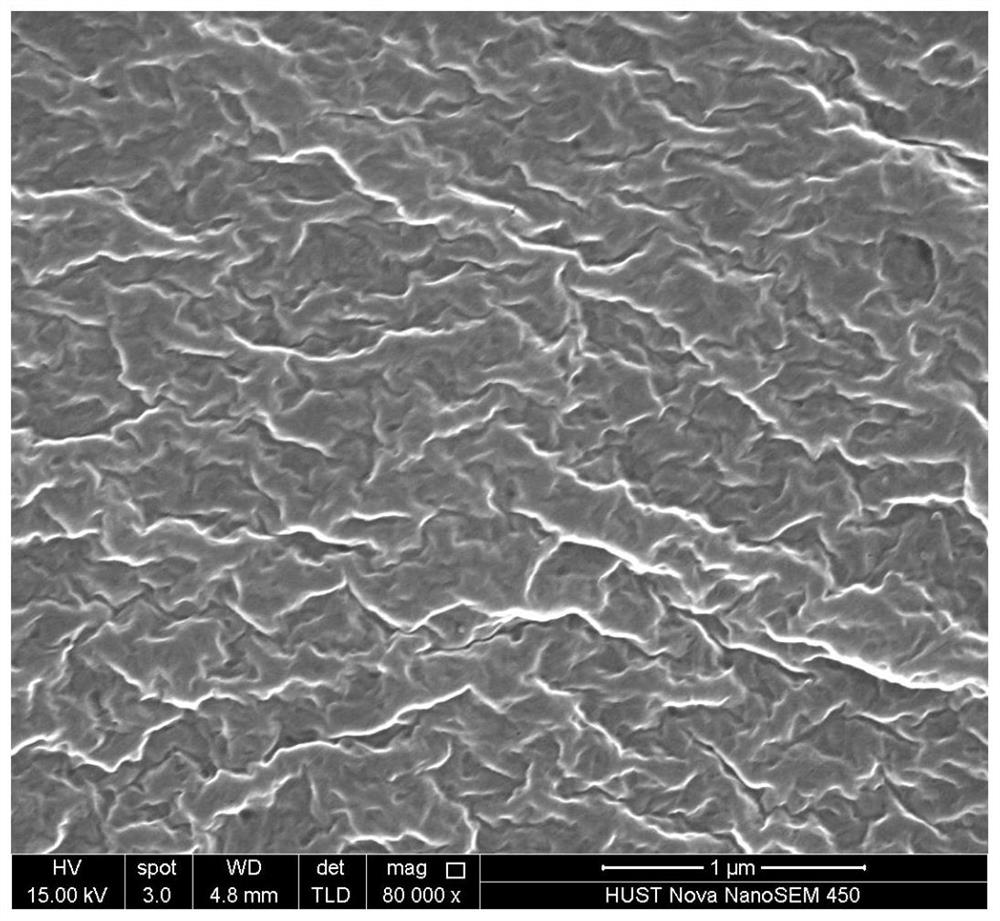

[0045] (1) Potassium hydroxide, deionized water, and aramid fiber polymer are added to dimethyl sulfoxide, stirred and dissolved at room temperature, and absolute ethanol is added drop by drop to prepare aramid fiber nanofiber slurry;

[0046] (2) coating the aramid nanofiber slurry obtained in step (1) on the surface of a polyolefin porous diaphragm to obtain a coating film;

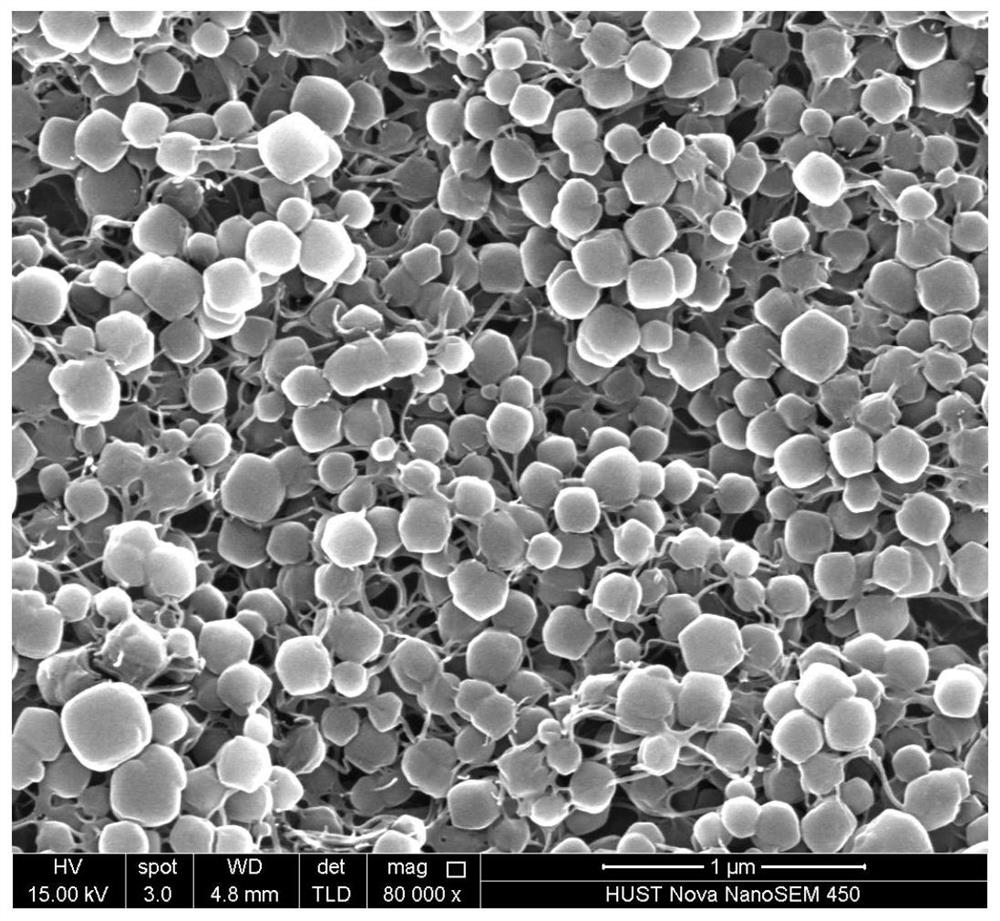

[0047] (3) soak the coating film obtained in step (2) into the replacement solvent, the first precursor solution and the second precursor solution respectively in order, and wash to obtain the coating film loaded with nanomaterials;

[0048] (4) Drying the nanomaterial-loaded coating film obtained in step (3) in a vacuum oven to obtain a nanomaterial-loaded aramid-coated battery separator.

[0049] Wherein, in the aramid fiber nanofiber slurry in step ...

Embodiment 1

[0060] The aramid-coated battery separator loaded with nanomaterials in this embodiment includes a polyolefin porous separator, an aramid coating coated on one side of the base film, and ZnS nanomaterials supported by aramid nanofibers coated with aramid. The aramid nanofiber slurry was coated on one side of the polyolefin porous diaphragm, soaked in deionized water, zinc salt solution, and sulfide salt solution successively, washed and dried to prepare a composite diaphragm for lithium-sulfur batteries. The component content of the aramid nanofiber slurry is: potassium hydroxide: 0.09g; deionized water: 1.2g; aramid polymer: 0.06g; dimethyl sulfoxide: 33g; the quality of absolute ethanol: 4.5g , the dropping rate is 0.05ml / s; the polyolefin porous diaphragm is a polyethylene microporous diaphragm; the thickness of the coating slurry is 30 μm; the zinc salt is zinc sulfate; the sulfide salt is sodium sulfide; the solvent is deionized water; zinc salt solution The concentration...

Embodiment 2

[0069] The aramid-coated battery separator loaded with nanomaterials in this embodiment includes a polyolefin porous separator, an aramid coating coated on one side of the base film, and ZnS nanomaterials supported by aramid nanofibers coated with aramid. The aramid nanofiber slurry was coated on one side of the polyolefin porous diaphragm, soaked in deionized water, zinc salt solution, and sulfide salt solution successively, washed and dried to prepare a composite diaphragm for lithium-sulfur batteries. The component content of the aramid nanofiber slurry is: potassium hydroxide: 0.18g; deionized water: 1.2g; aramid polymer: 0.12g; dimethyl sulfoxide: 33g; the quality of absolute ethanol: 8.1g , the dropping rate is 0.05ml / s; the polyolefin porous diaphragm is a polyethylene microporous diaphragm; the thickness of the coating slurry is 120 μm; the zinc salt is zinc sulfate; the sulfide salt is sodium sulfide; the solvent is deionized water; zinc salt solution The concentratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com