Preparation method of glucose-triggered active oxygen response injection type composite hydrogel

A composite hydrogel and glucose oxidase technology, applied in biochemical equipment and methods, medical preparations containing active ingredients, medical preparations with non-active ingredients, etc., can solve the problem of high-sugar environmental diseases, natural GOx Poor stability, short half-life in vivo, etc., to achieve excellent stability and mechanical properties, good biocompatibility, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

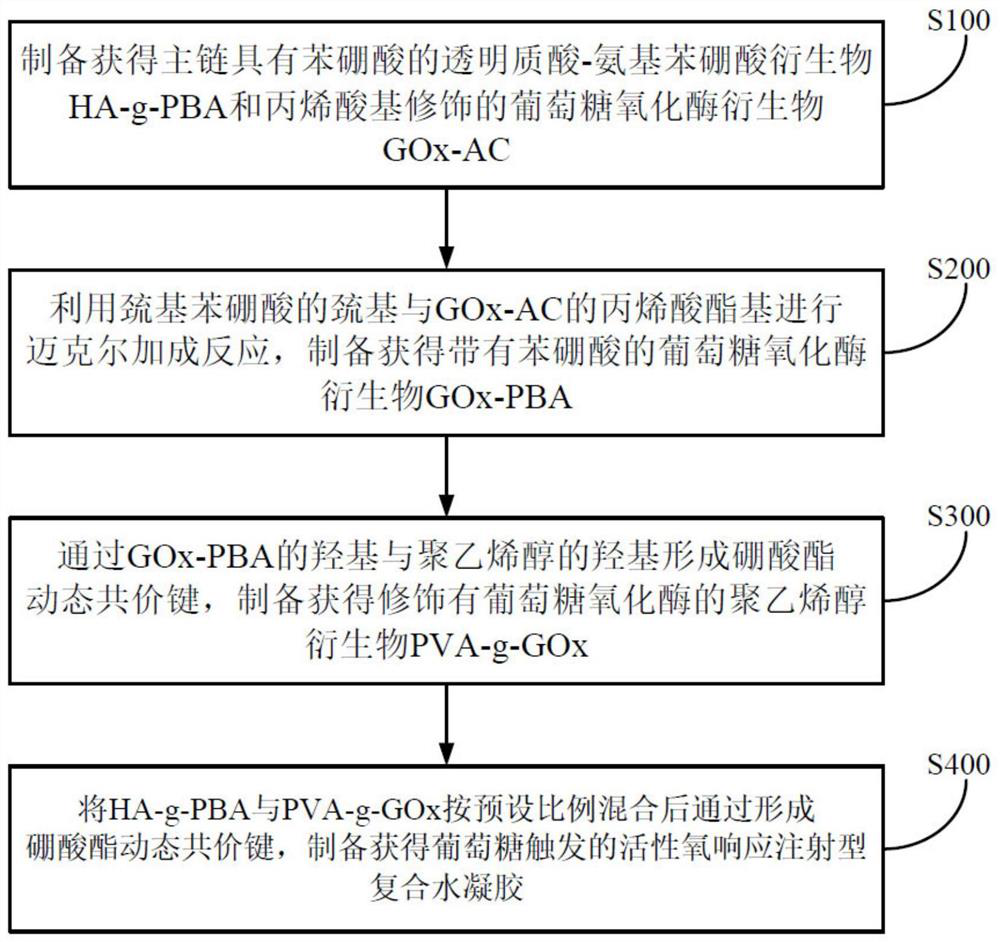

[0054] figure 1 A schematic flow chart showing a method for preparing a glucose-triggered reactive oxygen species-responsive injectable composite hydrogel according to an embodiment of the present invention. Such as figure 1 As shown, the preparation method of the active oxygen response injectable composite hydrogel comprises:

[0055] Step S100, preparing a hyaluronic acid-aminophenylboronic acid derivative HA-g-PBA with phenylboronic acid in the main chain and an acrylic acid-modified glucose oxidase derivative GOx-AC;

[0056] Step S200, using the Michael addition reaction between the thiol group of mercaptophenylboronic acid and the acrylate group of GOx-AC to prepare the glucose oxidase derivative GOx-g-PBA with phenylboronic acid;

[0057] In step S300, the hydroxyl group of GOx-g-PBA and the hydroxyl group of polyvinyl alcohol form borate dynamic covalent bonds to prepare polyvinyl alcohol derivative PVA-g-GOx modified with glucose oxidase;

[0058] Step S400, mixing...

Embodiment 1

[0090] A method for preparing a glucose-triggered active oxygen response injectable composite hydrogel, comprising the steps of:

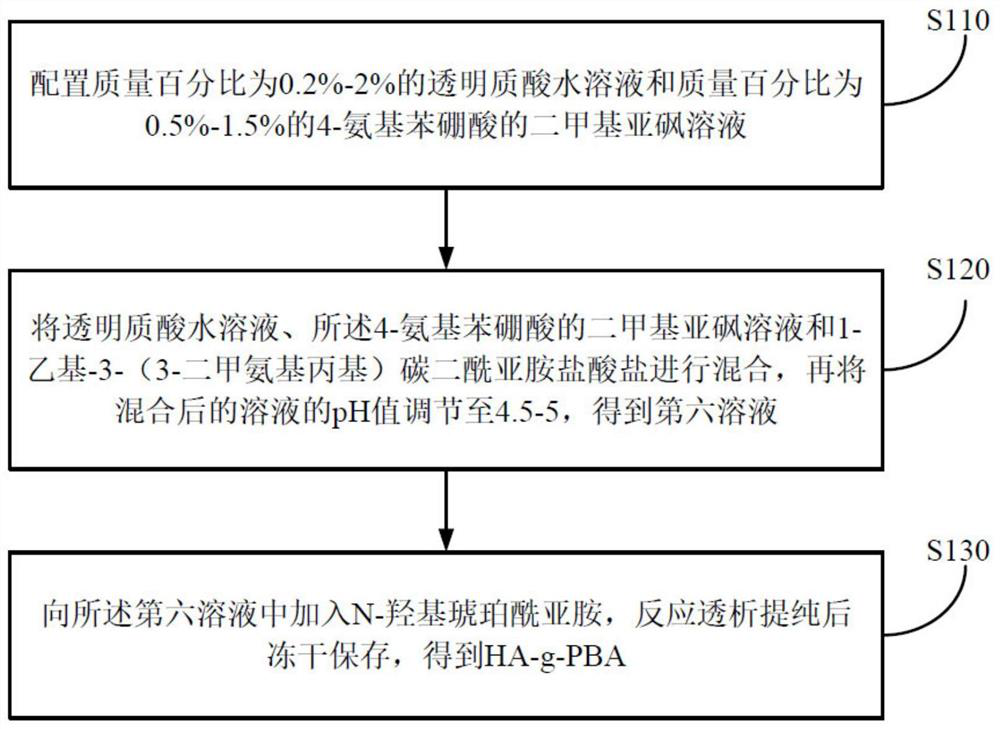

[0091] 1) Preparation of hyaluronic acid-aminophenylboronic acid derivative (HA-g-PBA)

[0092] Dissolve 2g HA (molecular weight 40KDa) in 800mL of ultrapure water, then add 690mg of 4-aminophenylboronic acid dissolved in 100mL of DMSO solution, then add 1530mg of 1-ethyl-3-(3-dimethylaminopropyl)carbon Diimide hydrochloride, and adjust the pH of the solution to 4.5-5.0 by hydrochloric acid, then add 920mg N-hydroxysuccinimide, and react for 6 hours; the product HA-g-PBA solution is purified by dialysis (using a molecular weight cut-off of 8- 10KDa dialysis bag) and freeze-dried for storage.

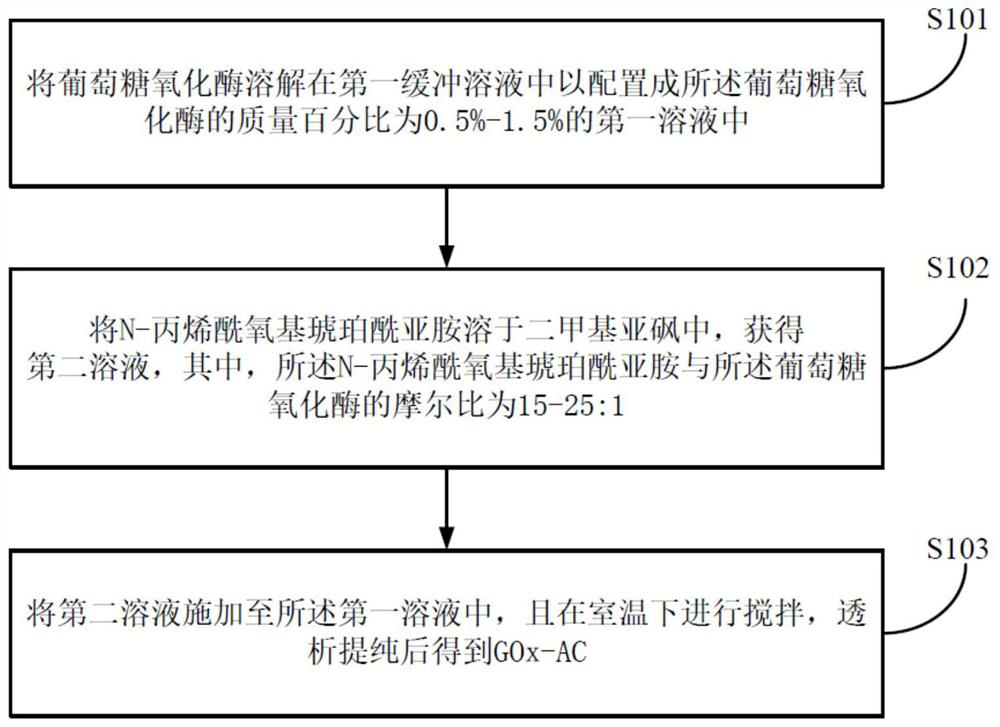

[0093] 2) Preparation of polyvinyl alcohol derivatives modified with glucose oxidase

[0094] Dissolve 50 mg of glucose oxidase in 5 mL of buffer solution (PBS, pH=7.4-8.0, 150 mM), and another 10 μL of N-acryloyloxysuccinimide 10% (w / v) DMSO solution was a...

Embodiment 2

[0100] A preparation method of glucose-triggered reactive oxygen species responsive injectable composite hydrogel, the preparation method comprising the following steps:

[0101] 1) Preparation of hyaluronic acid-aminophenylboronic acid derivative (HA-g-PBA)

[0102] Dissolve 2g HA (molecular weight 20KDa) in 800mL of ultrapure water, then add 1380mg of 4-aminophenylboronic acid dissolved in 100mL of DMSO solution, then add 3060mg of 1-ethyl-3-(3-dimethylaminopropyl)carbon Diimide hydrochloride, and adjust the pH of the solution to 4.5-5.0 by hydrochloric acid, then add 1920mg N-hydroxysuccinimide, and react for 6 hours; the product HA-APBA solution is purified by dialysis (molecular weight cut-off 8-10KDa dialysis bag ) and then freeze-dried.

[0103] 2) Preparation of polyvinyl alcohol derivatives modified with glucose oxidase

[0104] Dissolve 50 mg of glucose oxidase in 5 mL of buffer solution (PBS, pH=7.4-8.0, 150 mM), and another 10 μL of N-acryloyloxysuccinimide 10% (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com