High-molecular polymer solid water degradable cross-linking agent reaction method and device

A technology of high molecular polymer and reaction device, which is applied in chemical/physical/physical-chemical fixed reactors, feeding devices, chemical instruments and methods, etc. Reaction efficiency and uniformity, etc., to achieve the effect of improving water absorption, improving yield, improving hydrophilicity and swelling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

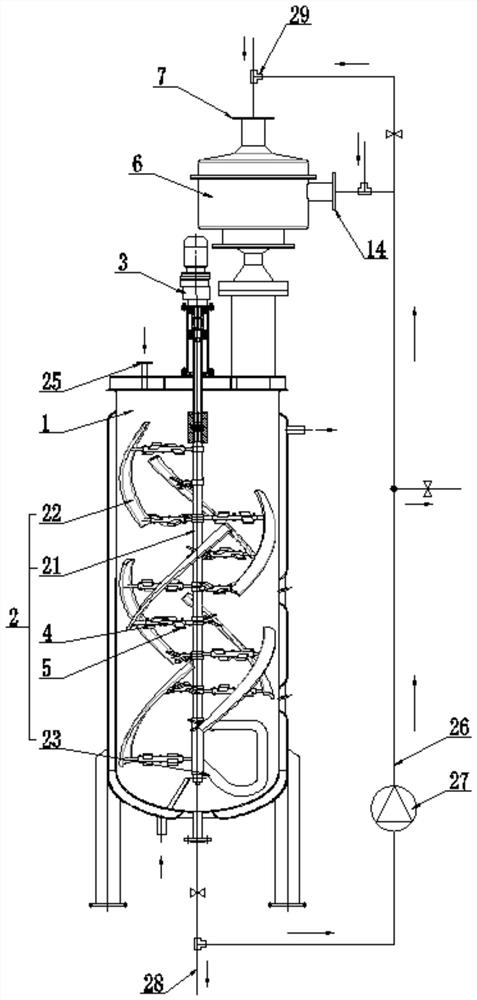

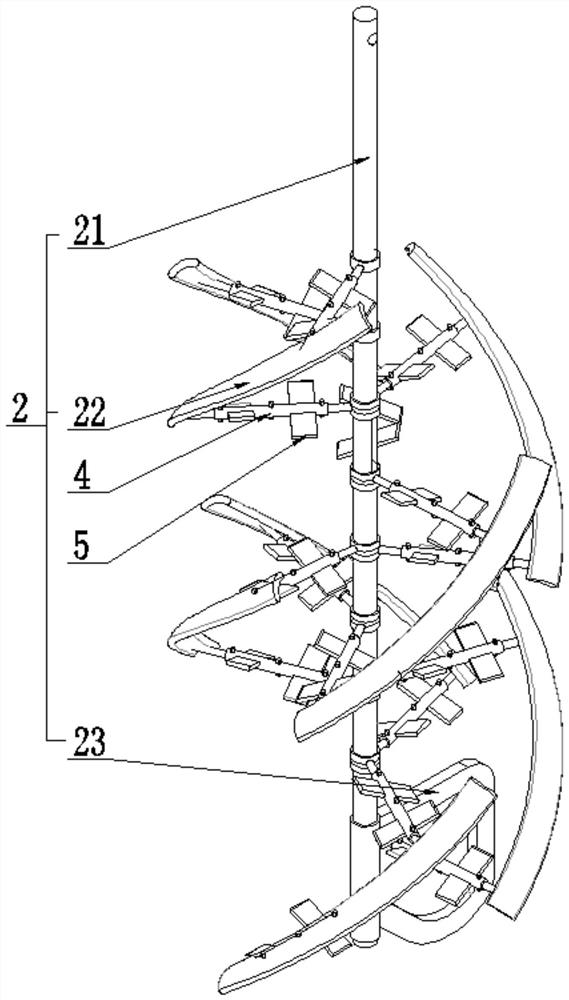

[0028] A kind of high molecular polymer solid water degradable crosslinking agent reaction method, its specific steps are:

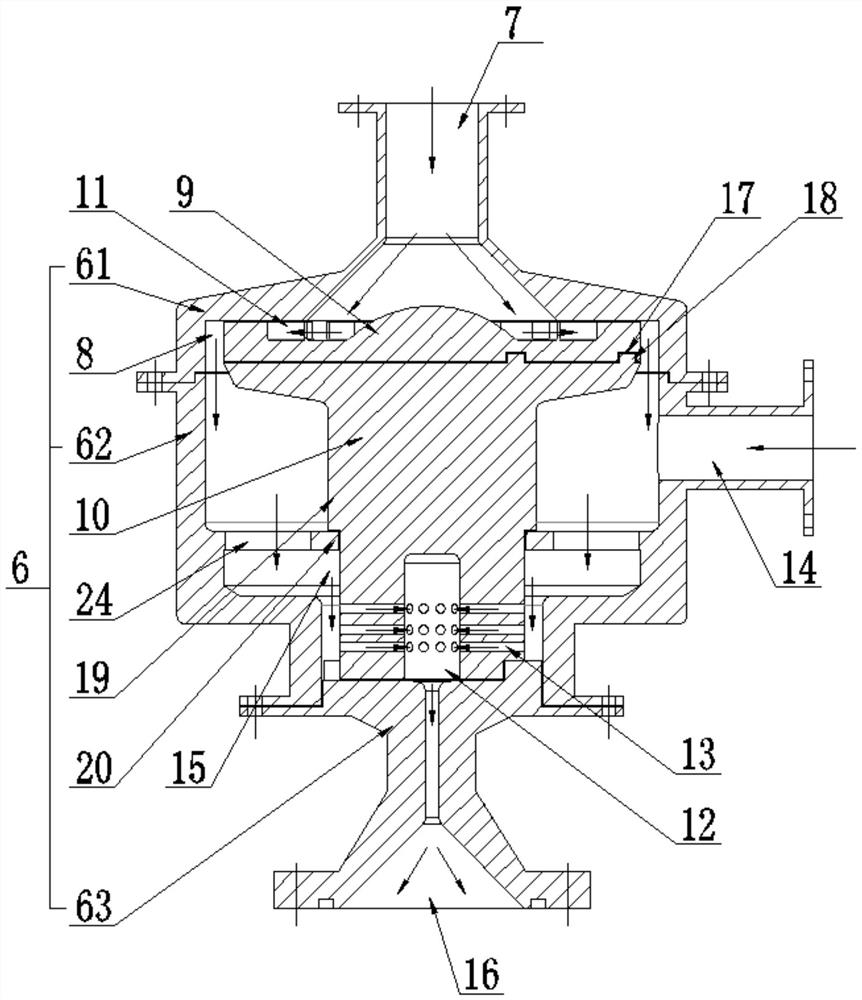

[0029] S1: Add 12kg of polyester, 130g of amino acid monomer, 100L of dimethyl sulfoxide, and 50L of dichloromethane into the reactor 1 from the feed pipe 25 at the top of the reactor 1 and stir for 15 minutes at a stirring rate of 120r / min. ; The polyester is polylactic acid, and the amino acid monomer is a combination of glycine and aspartic acid in a mass ratio of 1:1;

[0030] S2: Add 138g of acrylic acid into the reactor 6 from the feed pipe 25 of the upper inlet 7, control the three-way valve 29, open the circulation pump 27, and put the polyester, amino acid monomer, dimethyl sulfoxide and dichloro The mixed solution of methane enters the reactor 6 from the circulation pipe 26, through the side inlet 14, and enters the reactor 1 from the bottom outlet 16 in parallel flow, and stirs and circulates and disperses for 15 minutes at a stirring rate of ...

Embodiment 2

[0035] A kind of high molecular polymer solid water degradable crosslinking agent reaction method, its specific steps are:

[0036] S1: Add 14kg of polyester, 90g of amino acid monomer, 100L of dimethyl sulfoxide, and 50L of dichloromethane into the reactor 1 from the feed pipe 25 at the top of the reactor 1 and stir for 12 minutes at a stirring rate of 130r / min. ; The polyester is polycaprolactone, and the amino acid monomer is a combination of L-lysine and leucine in a mass ratio of 1:1;

[0037] S2: Add 165g of acrylic acid into the reactor 6 from the feed pipe 25 of the upper inlet 7, control the three-way valve 29, open the circulation pump 27, and put the polyester, amino acid monomer, dimethyl sulfoxide and dichloro The mixed solution of methane enters the reactor 6 from the circulation pipe 26 through the side inlet 14, and enters the reactor 1 from the bottom outlet 16 in parallel flow, and is stirred and circulated for 12 minutes at a stirring rate of 130 r / min;

[...

Embodiment 3

[0042] A kind of high molecular polymer solid water degradable crosslinking agent reaction method, its specific steps are:

[0043] S1: Add 8 kg of polyester, 100 g of amino acid monomer, 100 L of dimethyl sulfoxide, and 50 L of dichloromethane into the reactor 1 from the feed pipe 25 at the top of the reactor 1 and stir for 14 minutes at a stirring rate of 135 r / min. The polyester is composed of polylactic acid and polyvinyl alcohol in a mass ratio of 1:1, and the amino acid monomer is composed of serine and alanine in a mass ratio of 1:1;

[0044] S2: Add 90 g of acrylic acid into the reactor 6 from the feed pipe 25 of the upper inlet 7, control the three-way valve 29, and turn on the circulation pump 27, and the polyester, amino acid monomer, dimethyl sulfoxide and dichloromethane in the reactor 1 are The mixed solution of methane enters the reactor 6 from the circulation pipe 26 through the side inlet 14, and enters the reactor 1 from the bottom outlet 16 in parallel flow,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com