Positive material and its preparation method, lithium -ion battery

A cathode material, lithium source technology, applied in the field of lithium ion batteries, cathode materials and their preparation, can solve the problems of residual alkali on the surface of ternary cathode materials, battery capacity attenuation, etc., to improve cycle stability and service life, reduce Formation, good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0081] The application also provides a preparation method of a positive electrode material, such as Figure 4 As shown, the method includes the following steps S100-S200:

[0082] Step S100, the Ni x Co y M z oxide or Ni x Co y M z The hydroxide and the lithium source are mixed to obtain a mixture, and the mixture is sintered to obtain an active material, wherein 0.8≤x<1, 0<y+z≤0.2, and M is selected from Mn, Al, Cu, Zn, and Cr at least one of;

[0083] Step S200, adding the covalent-organic framework material and the active substance into a solvent to obtain a mixed solution, adding a metal salt to the mixed solution and mixing, then adding 2-methylimidazole, washing with water, stirring, filtering, drying, and sieving , to obtain the positive electrode material.

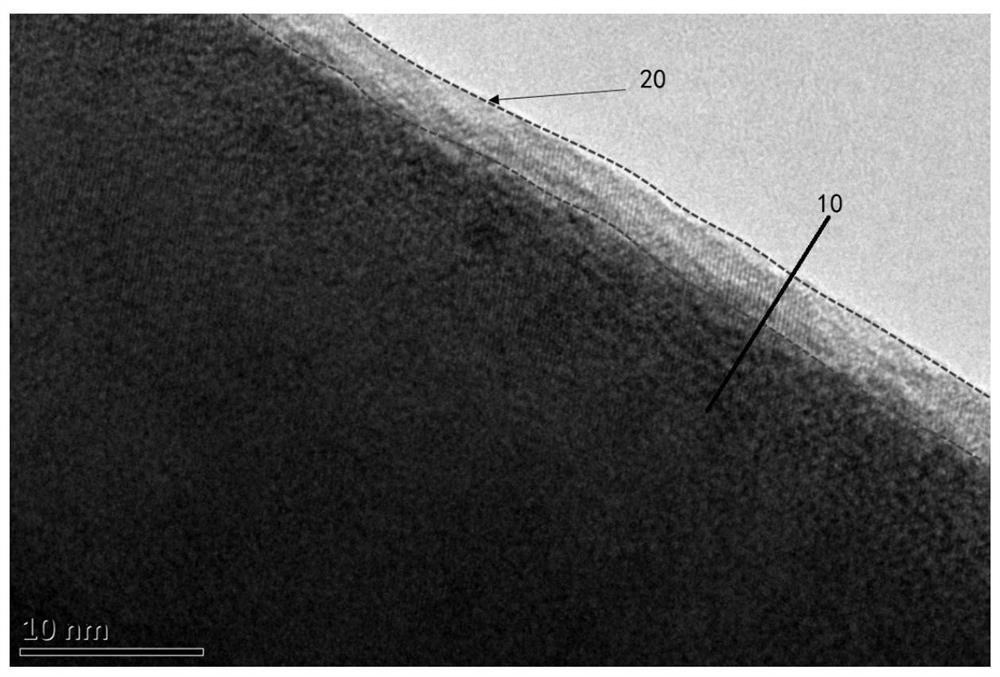

[0084] In the preparation method provided in this application, the active material obtained by sintering is added to a solvent together with covalent-organic framework materials (COFs), so that the COFs mat...

Embodiment 1

[0115] A preparation method of a positive electrode material, comprising the following steps:

[0116] (1) The nickel-cobalt-manganese precursor Ni 0.8 Co 0.1 Mn 0.1 (OH) 2 After mixing with LiOH in a molar ratio of 1:1.05, dry grinding at 25°C for 1 hour to obtain a mixture;

[0117] (2) The mixture was pre-sintered at 450°C for 5h in a muffle furnace, ground to fine particles, and then transferred to a tube furnace for high-temperature sintering in an oxygen atmosphere for 15h. The sintering temperature was controlled at 750°C, and the sintered active material was ground to The average particle size is 15μm;

[0118] (3) prepare a reaction kettle device that can be stirred and heated, add 0.3g of covalent organic framework material (COF-1) and 10g of active material while stirring to 200ml of deionized water, and after heating for 30min, then in the reaction kettle Add 0.15g zinc acetate dihydrate, 0.05g cobalt acetate tetrahydrate, stir evenly, slowly add 0.056g 2-meth...

Embodiment 2

[0122] A preparation method of a positive electrode material, comprising the following steps:

[0123] (1) The nickel-cobalt-manganese precursor Ni 0.8 Co 0.1 Mn 0.1 (OH) 2 After mixing with LiOH in a molar ratio of 1:1.03, dry grinding at 30°C for 1.5 hours to obtain a mixture;

[0124] (2) The mixture was placed in a muffle furnace at 470°C for pre-sintering for 5h, ground to fine particles, and then transferred to a tube furnace for high-temperature sintering in an oxygen atmosphere for 13h. The sintering temperature was controlled at 720°C, and the sintered active material was ground to The average particle size is 13 μm;

[0125] (3) prepare a reactor device that can be stirred and heated, add 0.4g of covalent organic framework material (COF-102) and 10g of active material while stirring in 400ml of deionized water, after heating for 30min, then in the reactor Add 0.13g of zinc acetate dihydrate, 0.05g of cobalt acetate tetrahydrate, stir evenly, slowly add 0.05g of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com