Compound, preparation method thereof, electrochromic material, electrochromic device and preparation method ofelectrochromic device

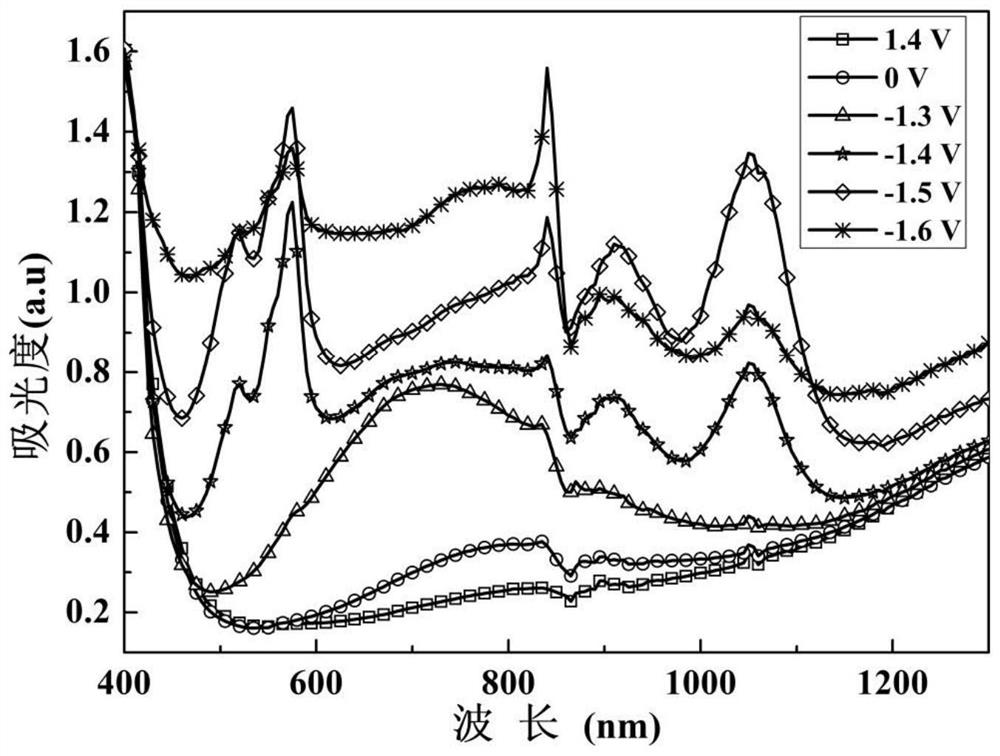

A technology of electrochromic devices and electrochromic materials, which is applied in the field of color-changing materials, can solve the problems of complex preparation process and relatively high material solubility requirements, and achieve the effect of simple preparation process, simple and easy preparation method, and fast discoloration speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] According to another aspect of the present invention, the present invention also relates to the preparation method of said compound, comprising the following steps:

[0042] The mixture of raw material B, raw material C and organic solvent is reacted under heating conditions;

[0043] The raw material C is iodopentane or bromopentane;

[0044] The raw material B has the structure described in formula (II):

[0045]

[0046] The preparation method of the compound in the invention is simple and easy, and the product yield is high.

[0047] Preferably, the first organic solvent includes 1,4-N,N-dimethylformamide (DMF).

[0048] Preferably, the molar ratio of the raw material B to the raw material C is (0.8-1): (3-4).

[0049] In one embodiment, the molar ratio of the raw material B to the raw material C is 0.8:3, 0.84:3.5, 0.9:3.7 or 1:4.

[0050] Preferably, the heating temperature is 60-80°C.

[0051] Preferably, the reaction time is 65-80 hours.

[0052] In one...

Embodiment 1

[0101] A preparation method of a compound, comprising the following steps:

[0102] Compound A (2,5-dibromothiophene) (424mg, 1.77mmol), 4-pyridineboronic acid pinacol ester (1g, 4.9mmol), tetrakistriphenylphosphopalladium (204mg, 0.176mmol) and potassium phosphate ( 2.98g, 14.1mmol) into a 25mL round bottom flask, and then add 10mlL of 1,4-N,N-dimethylformamide (DMF) and dioxane mixed solution (the volume ratio of the two is 1:1 ), use the bubbling method to degas for 30 minutes, then heat the reaction solution to 130 ° C, react under nitrogen atmosphere for 72 hours, cool to room temperature and filter; the organic phase is concentrated in vacuo, and the residue is washed with chloroform CHCl 3 Dissolve, wash three times in deionized water, then add concentrated hydrochloric acid HCl (about 1 mL) to the organic phase to precipitate the product from solution, the precipitate is collected by filtration, then dissolved in water, finally, sodium hydroxide (NaOH, 15M ) aqueous s...

Embodiment 2

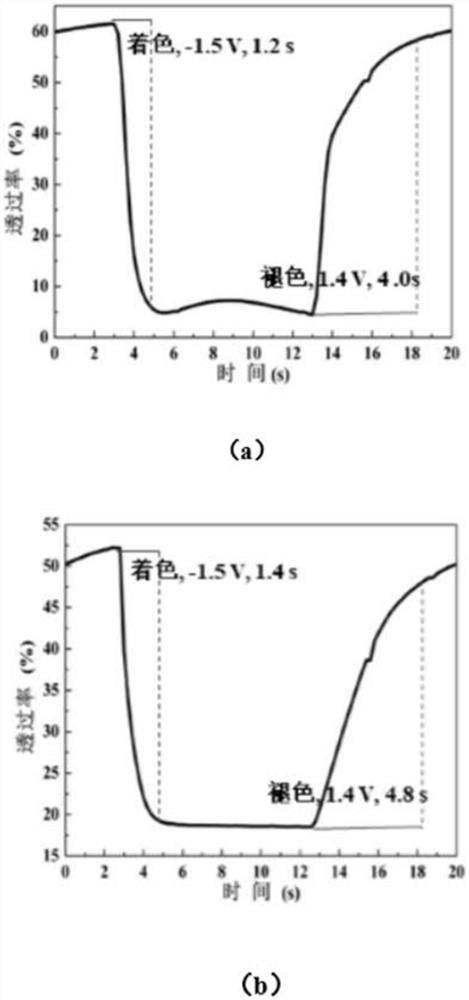

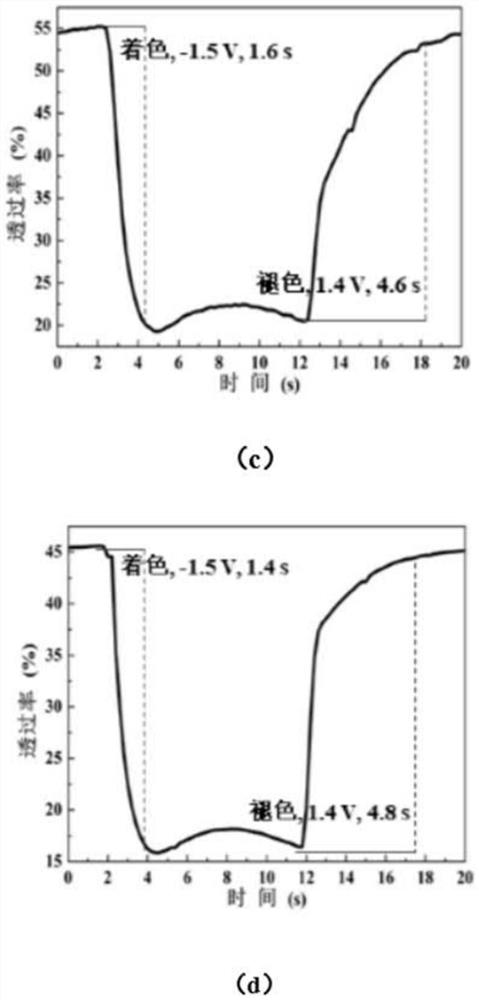

[0108] An electrochromic device such as Figure 4 As shown, it includes a first conductive layer 1, an electrolyte gel-film layer 3 and a second conductive layer 2; the electrolyte gel-film layer is located between the first conductive layer 1 and the second conductive layer 2;

[0109]Among them, the electrolyte gel-film layer 3 is mainly composed of electrolyte gel and Parafilm film, the thickness of Parafilm film is 80 μm, and the Parafilm is provided with round holes with a diameter of 16 mm; the electrolyte gel is at least covered with the round holes on the Parafilm The electrolyte gel is mainly composed of electrolyte and the compound TBPP prepared in Example 1, and the electrolyte is lithium perchlorate;

[0110] The first conductive layer 1 is ITO conductive glass; the second conductive layer 2 is an ITO conductive glass whose surface is coated with a Prussian blue film layer 4;

[0111] The preparation method of the color-changing device of the present embodiment co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com