Preparation method and application of non-metal water-soluble heavy metal adsorbent based on reversible phase transition

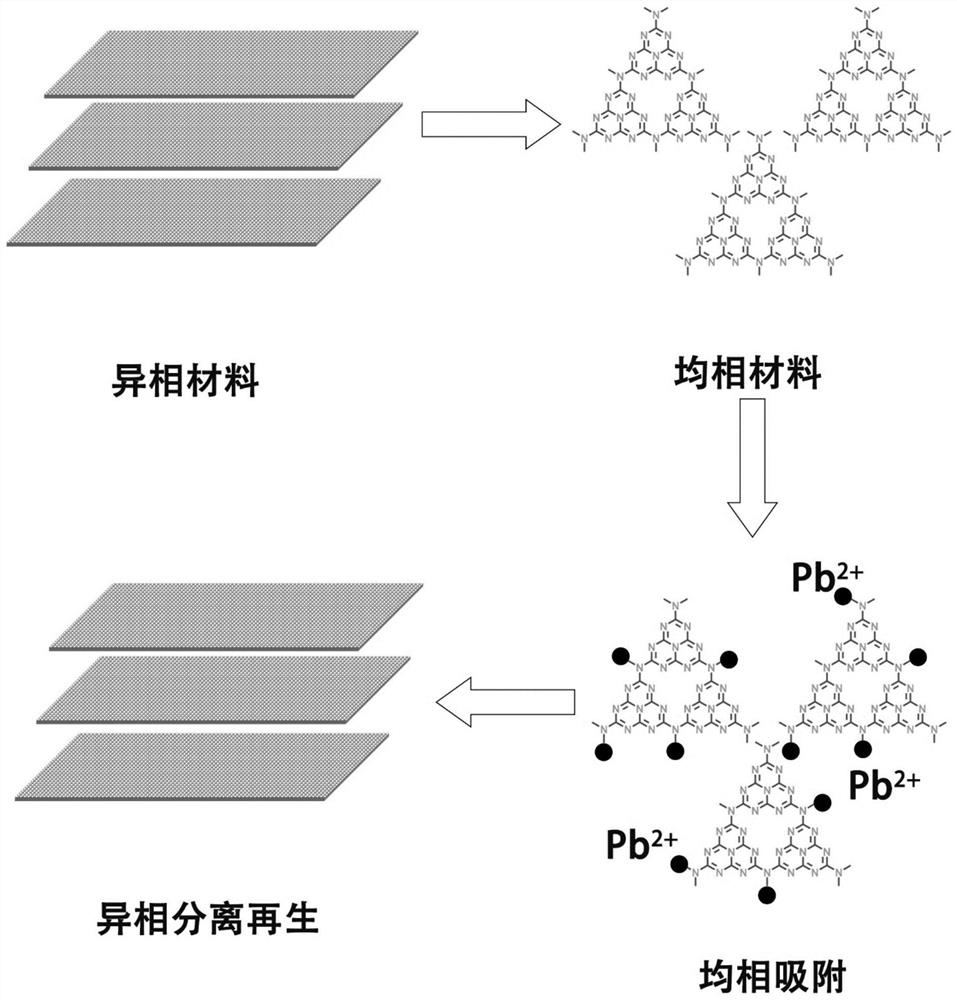

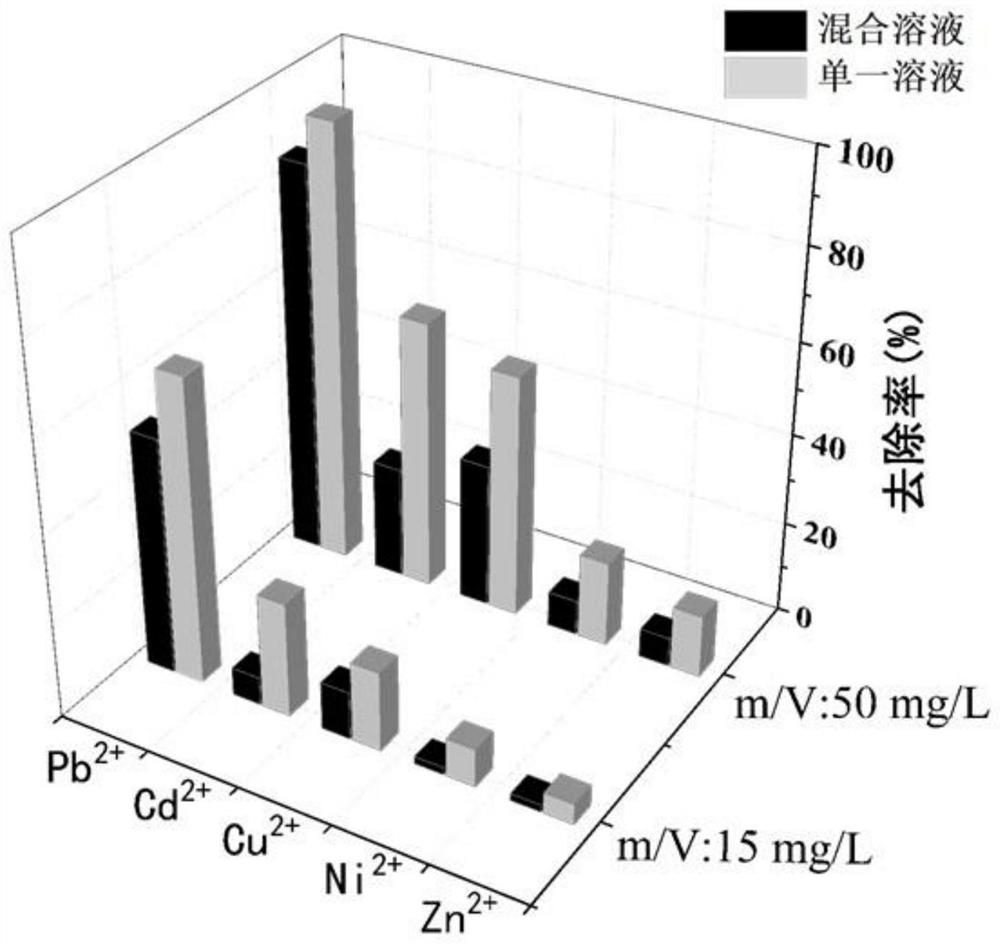

A technology of heavy metals and adsorbents, applied in chemical instruments and methods, adsorption of water/sewage treatment, water pollutants, etc., can solve problems such as difficult to achieve capture agent molecule recycling, secondary pollution, etc., to achieve good selectivity, preparation The process is simple and the effect of increasing the mass transfer rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

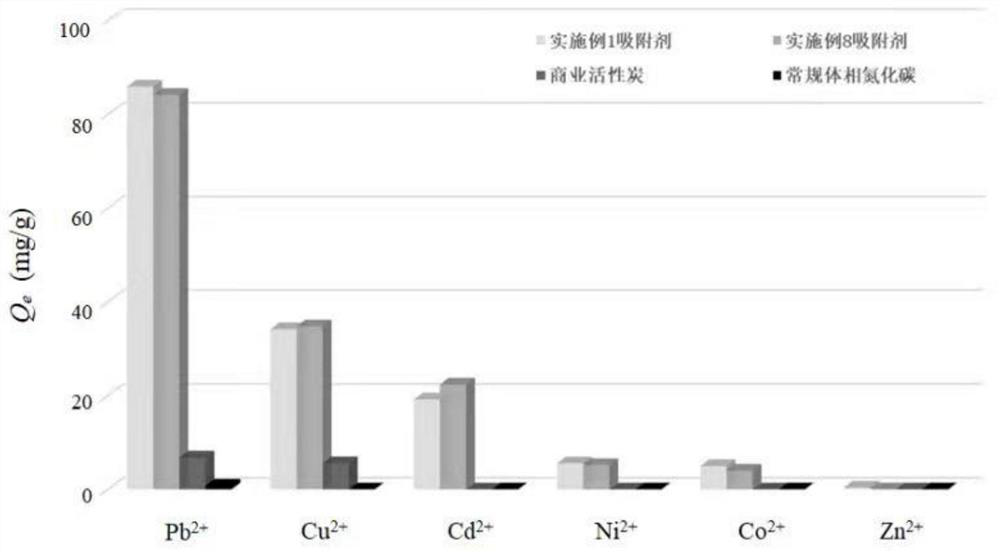

Examples

Embodiment 1

[0050] The preparation method of non-metallic water-soluble dissolved adsorbent comprises the steps:

[0051](1) Weigh 6 g (0.048 mol) of melamine, 0.8 g (0.02 mol) of sodium hydroxide, and 2.24 g (0.04 mol) of potassium hydroxide, and grind them thoroughly in a mortar to obtain a mixture.

[0052] (2) Add the mixture obtained in (1) into a covered crucible, put it into a muffle furnace and raise it from room temperature to 330 °C at a rate of 5 °C / min and keep it for 2 hours. After cooling to room temperature, it is fully ground into powder.

[0053] (3) Dissolve the powder obtained in (2) in 400ml ultrapure water, and then put it into a 3500Da dialysis bag for dialysis for 4 days to obtain a non-metallic water-soluble adsorbent based on the reversible phase transition function.

Embodiment 2

[0055] The difference between the present application and Example 1 is that the raw material consumption of the present example is different from Example 1, and the difference is as follows: 6g (0.048mol) melamine and 0.8g (0.02mol) sodium hydroxide are fully ground in a mortar, Obtain the mixture, then take the calcination and dialysis process of Example 1 to obtain the non-metallic water-soluble adsorbent.

Embodiment 3

[0057] The difference between the present application and Example 1 is that the raw material consumption of the present example is different from Example 1, and the difference is as follows: 6g (0.048mol) melamine and 2.44g (0.04mol) potassium hydroxide are fully ground in a mortar, Obtain the mixture, then take the calcination and dialysis process of Example 1 to obtain the non-metallic water-soluble adsorbent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com