Micro-emulsified biodegradable metal working fluid with low carbon footprint as well as preparation method and application thereof

A metalworking fluid and biodegradable technology, applied in the petroleum industry, lubricating compositions, etc., can solve problems such as not easy to biodegrade, endanger the health of operators, pollute the workshop environment, etc., to increase the degradability rate, prolong the life of the tool, metal good protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Isopropanolamine 4.7%, nano-silicon corrosion inhibitor 2%, triazine polycarboxylate 4%, benzotriazole 1%, self-emulsifying ester 5%, tall oil 5%, dioctyl terephthalate 48 %, Guerbet alcohol 3%, ether carboxylic acid formulation 2%, cardanol 13%, potassium hydroxide 0.3% and water 12%.

Embodiment 2

[0052] Isopropanolamine 2%, nano-silicon corrosion inhibitor 1%, triazine polycarboxylate 3%, benzotriazole 1%, self-emulsifying ester 4%, tall oil 4%, dioctyl terephthalate 50 %, Guerbet alcohol 2%, ether carboxylic acid formulation 1%, cardanol 10%, potassium hydroxide 0.2% and water 21.8%.

Embodiment 3

[0054] Isopropanolamine 6%, nano-silicon anticorrosion agent 3%, triazine polycarboxylate 6%, methylbenzotriazole 3%, self-emulsifying ester 6%, tall oil 6%, dioctyl terephthalate Ester 40%, Guerbet alcohol 4%, ether carboxylic acid formulation 4%, cardanol 10%, potassium hydroxide 0.3% and water 11.7%.

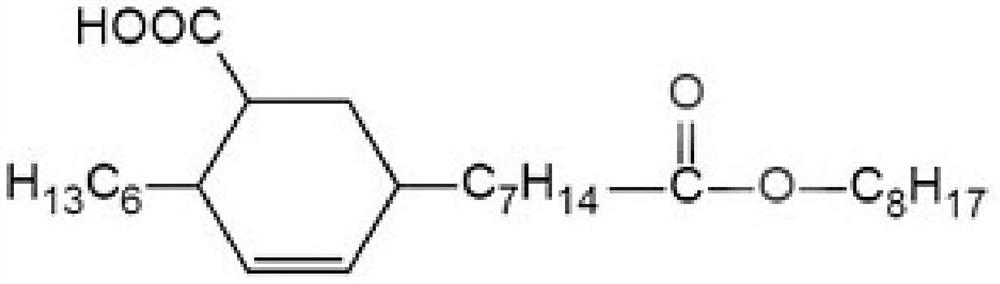

[0055] The basic information of chemical additives involved in the present invention is as follows:

[0056] Isopropanolamine: Isopropanolamine is an important corrosion inhibitor that can be used in boiler water treatment, coolant for automobile engines, drilling and cutting oils, and other types of lubricating oils.

[0057] Nano-silicon corrosion inhibitor: one or more of aminopropyltriethoxysilane, aminopropyltrimethoxysilane, and aminopropylmethyldiethoxysilane, which can be used for metal cleaning and cutting fluid. It is used as an anti-corrosion agent in metal working lubricating fluids of aluminum, magnesium, zinc and other metals, and also has very good lubrication...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com