Iron-based organic framework composite material, preparation method and application thereof

A technology of organic framework and composite materials, applied in organic compound/hydride/coordination complex catalysts, chemical instruments and methods, water treatment of special compounds, etc., can solve the limitations of photocatalytic performance, photogenerated electrons and hole recombination rate High, photocatalytic degradation activity and other issues, to achieve the effect of reducing the recombination rate of photogenerated electrons and holes, promoting charge transfer, and inhibiting recombination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1.1 preparation

[0031] The iron-based organic skeleton composite prepared by the present invention has visible light response, has a heterojunction structure, and the optical electron-hole pair separation efficiency is high, and the specific implementation steps are as follows:

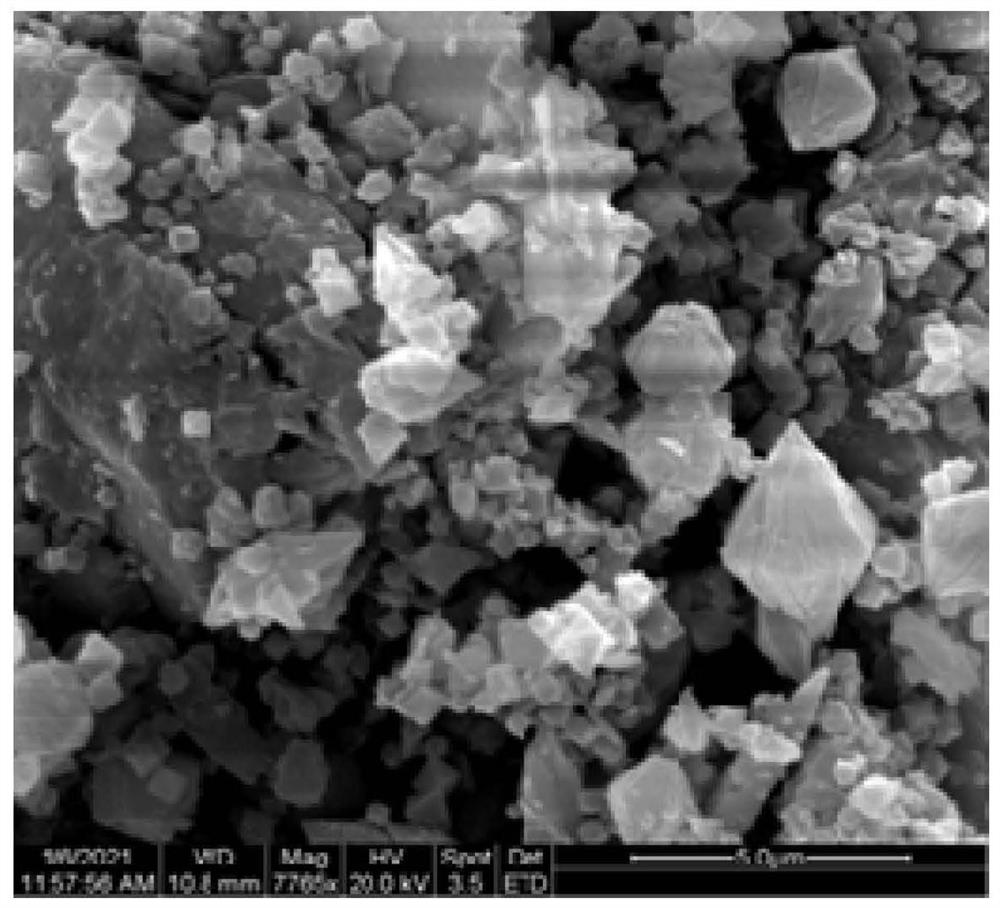

[0032] 3.00 g of melamine is loaded into a 50 ml ceramic crucible, adding 550 ° C in a muffle to heat 3 h (at 5 ° C · min -1 Temperature temperature), after natural cooling, take out with agate mortar to get G-C 3 N 4 . Preparation of solvent heat method, weighing 1.5000GFECL 3 · 6h 2 O and 0.9219G (with FeCL 3 · 6h 2 O substance ratio is 1) h 2 BDC, and 0.1459g (FECL 3 · 6h 2 O The ratio of the amount of its substance is 3.5) G-C 3 N 4 Decoluble in 30 ml of DMF, stirred for 30 min, using an ultrasonic cell crusher to transfer 100 ml of polytetrafluoroethylene liner stainless steel reactor, add 150 ° C in a muffle 12h (at 5 ° C · min. -1 After cooling, naturally cooled to room temperature, 8000r ...

Embodiment 2

[0057] Material composite molar ratio to MIL-53 (Fe) / G-C 3 N 4 / PMS / VIS Degradation of RHB

[0058] Modify the FeCl in Example 1 3 · 6h 2 O and G-C 3 N 4 The ratio of the molar, the other operation is the same as in Example 1.

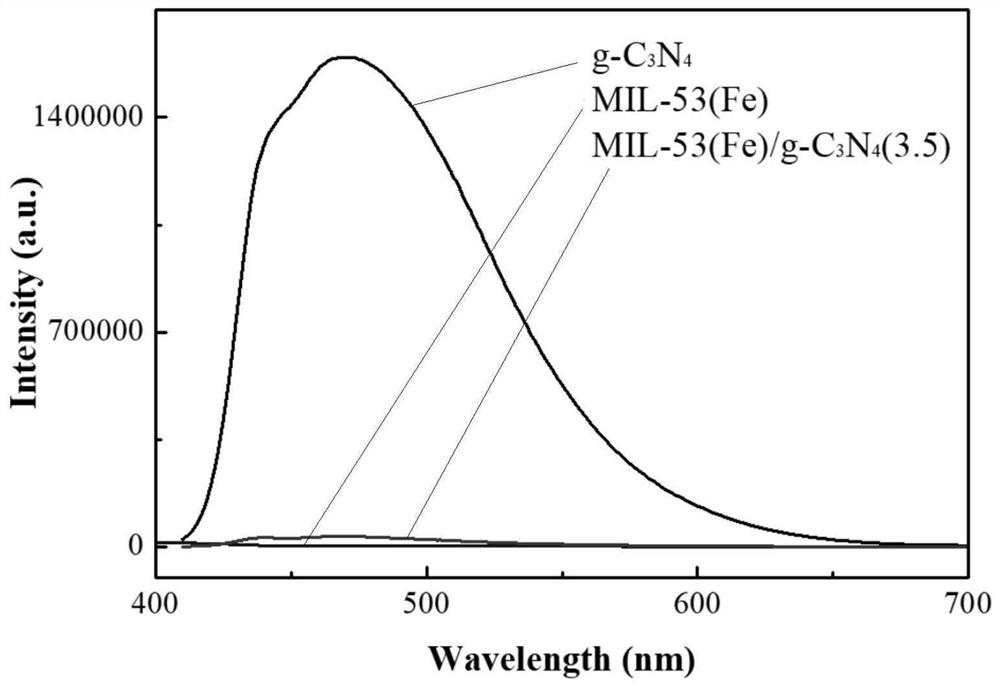

[0059] The catalytic material of different composite ratios is different from the RHB removal effect, such as Figure 8 The MIL-53 (Fe) / G-C shown in different composite ratios 3 N 4 The removal effect of RHB is: with G-C 3 N 4 Increase in content, the removal rate of RHB presets the trend of reducing, MIL-53 (Fe) / G-C 3 N 4 When the compound ratio X of the catalytic material is less than 3.5, the removal rate of RHB increases and the degradation rate is significantly increased, which is due to G-C 3 N 4 The introduction enables MIL-53 (Fe) absorption wavelength range to redirement, improves the response performance of visible light, and the heterojunction formed between the two can reduce G-C. 3 N 4 Light electron and hole composite; with G-C 3 N 4 ...

Embodiment 3

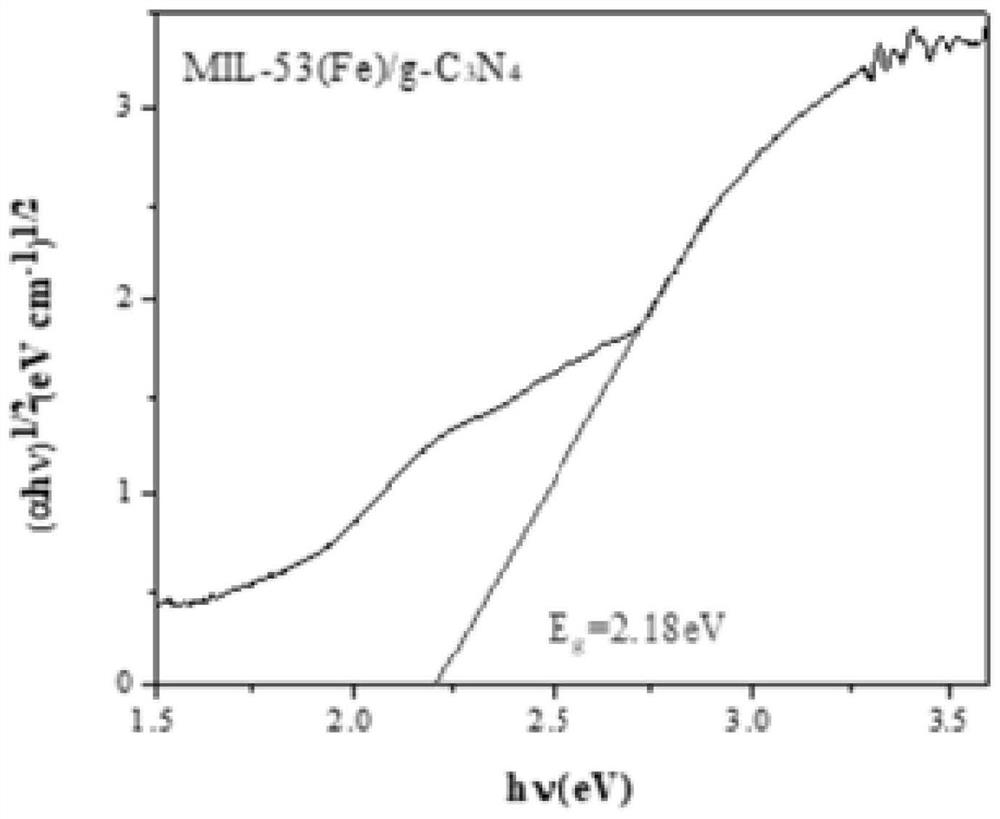

[0061] Test MIL-53 (Fe), G-C at 200-800 nm wavelength range 3 N 4 , Three composite ratios MIL-53 (Fe) / G-C 3 N 4 Ultraviolet - visible light diffuse reflection spectroscopy (UV-VIS DRS) gets light suction value, such as Figure 9 Analysis of the advantages of composites in light absorption performance and band gap. According to the TAUC diagram according to the formula (3.1), wherein when the material is a direct transition semiconductor, n = 2, and n = 2 is used for the indirect transition semiconductor.

[0062] (αHV) n = A (HV-E g ) Formula (3.1)

[0063]

[0064] Therefore, MIL-53 (Fe) and MIL-53 (Fe) / G-C 3 N 4 Composite N value selection 1 / 2, g-c 3 N 4 For n = 2, (αHV) n For the longitudinal axis, HV is the horizontal axis, such as Figure 10 As shown, the banned band width e obtained by each material is calculated. g And maximum absorption with edge λ max (Formula 3.2). MIL-53 (Fe), G-C 3 N 4 , MIL-53 (Fe) / G-C 3 N 4 (3.5), MIL-53 (Fe) / G-C 3 N 4 (3), MIL-53 (Fe) / G-C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com