Light absorption material constructed by A and X site coordinated regulation as well as preparation method and application thereof

A light-absorbing material, cubic phase technology, applied in the preparation of organic compounds, the preparation of amino compounds, chemical instruments and methods, etc., can solve the problems of structural phase transition, ion migration, poor stability, etc., and achieve high photoelectric conversion efficiency and large applications. Value, good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) PbI 2 (0.70~0.90mmol), Pb(SCN) 2 (0.10~0.30mmol), CH 3 NH 3 I (0.70~0.95mmol) and (CH 3 ) 2 NH 2 I (0.05-0.30 mmol) was dissolved in a mixed solvent of dimethyl sulfoxide and pyrrolidone (volume ratio 8:1) to obtain a yellow transparent solution (ie, the precursor solution);

[0039] (2) Coating the precursor solution to form a film by a liquid phase method, and then performing surface treatment with 0.5-2.0 mL cyclohexane solution to obtain a precursor film;

[0040] (3) Place the precursor thin film in a nitrogen atmosphere, and perform annealing treatment (crystallization) on a hot stage at 70-110° C. for 0.5 hours to obtain a perovskite thin film (light-absorbing layer). The chemical formula of the gained light absorbing layer is (CH 3 NH 3 ) 0.70~0.95 ((CH 3 ) 2 NH 2 ) 0.30~ 0.05 PB 2.40~2.80 SCN 0.60~0.20 , with a thickness of about 500 nm.

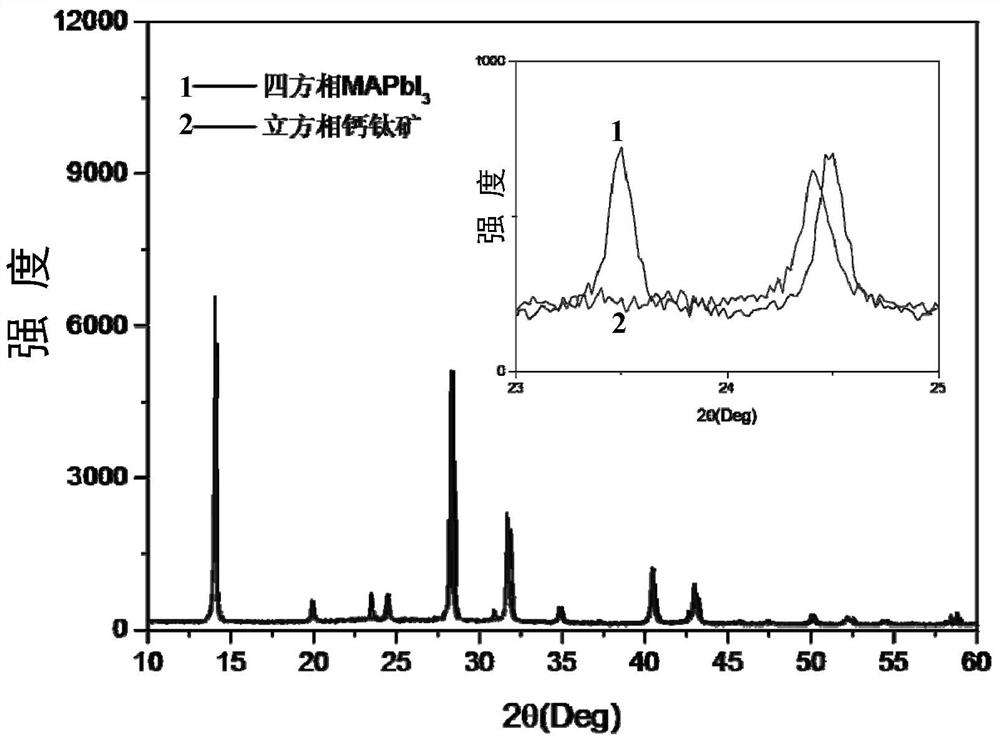

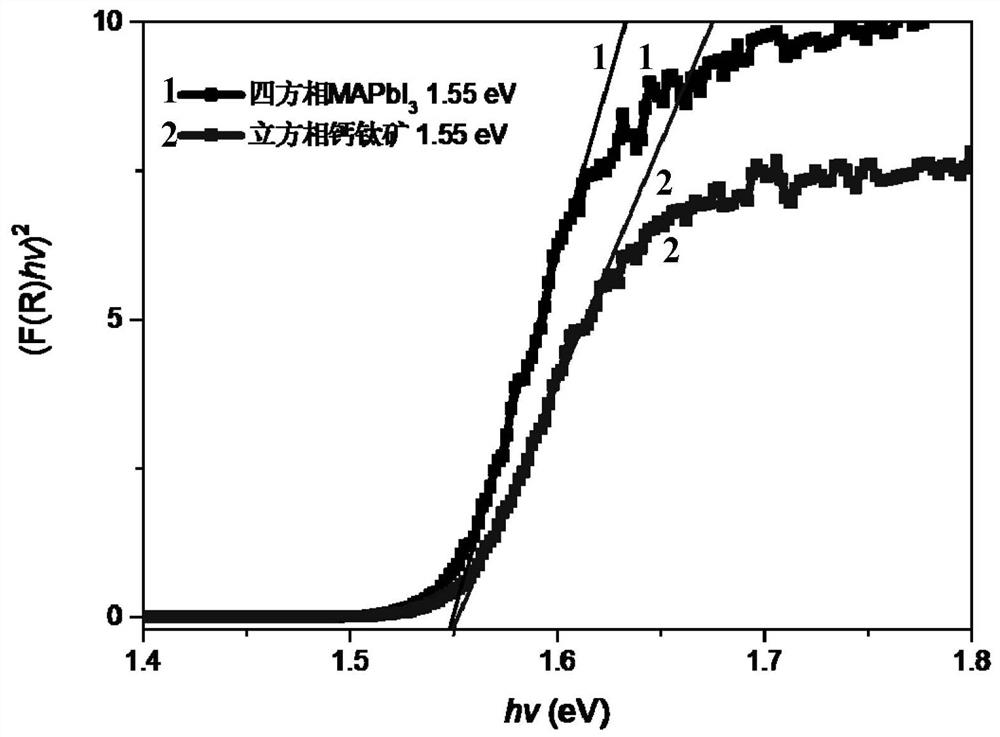

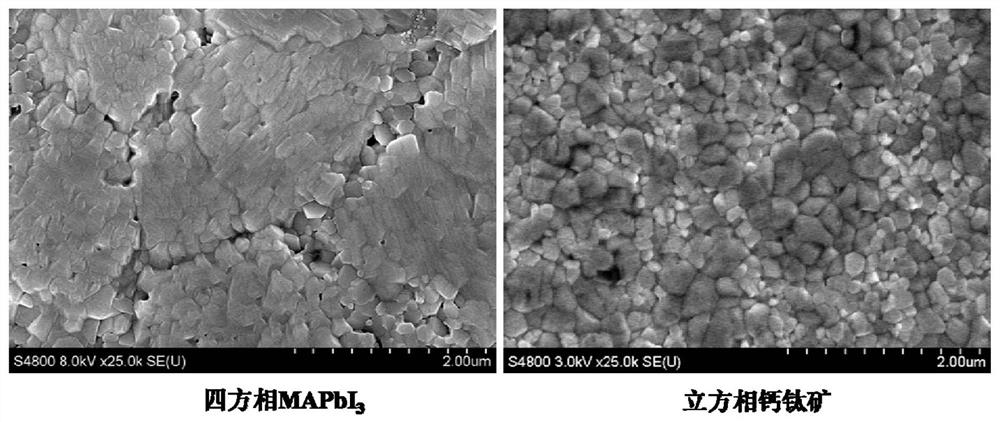

[0041] Carry out X-ray diffraction test with the obtained perovskite thin film of present embodiment 1...

Embodiment 2

[0046] (1) PbI 2 (1.0mmol), CH 3 NH 3 I (0.70~0.90mmol), CH 3 NH 3 BF 4 (0.05~0.15mmol) and (CH 3 ) 2 NH 2 I (0.05~0.15mmol) and ionic liquid (0.02~0.05mmol) were dissolved in a mixed solvent of dimethyl sulfoxide and N,N-dimethylformamide (10:1) to obtain a yellow transparent solution;

[0047] (2) Coating the yellow transparent solution into a film by liquid phase to obtain a precursor film;

[0048] (3) Place the obtained precursor thin film directly on a hot stage at 70-110° C. for 0.5 hour annealing treatment in a nitrogen atmosphere to obtain a cubic phase perovskite thin film. The chemical formula of the gained light absorbing layer is (CH 3 NH 3 ) 0.85~0.95 ((CH 3 ) 2 NH 2 ) 0.15~ 0.05 PB 2.85~2.95 (BF 4 ) 0.15~0.05 , with a thickness of about 600nm.

[0049] Refer to Example 1 for the material selection and preparation process of other layers of the solar cell in Example 2. The photoelectric conversion efficiency of the solar cell obtained reaches ...

Embodiment 3

[0051] (1) PbI 2 (1.0mmol), CH 3 NH 3 I (0.60~0.80mmol), CH 3 NH 3 BF 4 (0.10~0.20mmol) and (CH 3 CH 2 )NH 3 I (0.10~0.20mmol) was dissolved in a mixed solvent of dimethyl sulfoxide and N,N-dimethylformamide (5:1) to obtain a yellow transparent solution;

[0052] (2) Coating the yellow transparent solution into a film through the liquid phase, and placing it in methylamine vapor for 10 minutes to obtain a precursor film;

[0053](3) Place the obtained precursor thin film directly on a hot stage at 70-110°C in dry air for 0.5 hour annealing treatment to obtain a cubic phase perovskite thin film. The chemical formula of the gained light absorbing layer is (CH 3 NH 3 ) 0.80~0.90 (CH 3 CH 2 NH 3 ) 0.20~ 0.10 PB 2.80~2.90 (BF 4 ) 0.20~0.10 , with a thickness of about 700nm.

[0054] The solar cell structure in this embodiment 3 is FTO conductive glass substrate / SnO 2 / Perovskite / spiro-MeOTAD / Au. where SnO 2 Prepared by atomic layer deposition process, the thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com