Coating method for cavity surface of semiconductor laser chip

A laser and semiconductor technology, used in semiconductor lasers, lasers, laser parts, etc., can solve the problems of poor product reliability, affecting product service life, unstable laser performance, etc., to improve service life and reliability. , The effect of moisture isolation, long-term aging performance and anti-static ESD ability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A method for coating a cavity surface of a semiconductor laser chip, comprising the steps of:

[0049] 1) Carry out bar strip cleavage and clip strips for the chip to be coated, and quickly put it into the evaporation coating equipment (to ensure that the product is exposed to the air as short as possible after cleavage), vacuumize, ensure a high vacuum environment, and reduce Process impurity gas, improve product surface activity;

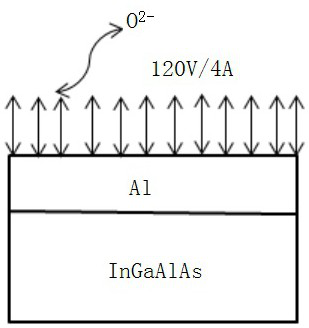

[0050] 2) Perform ion source pre-cleaning treatment on the surface of the optical cavity of the chip; the specific process is: wait for the vacuum degree in the equipment to reach 2.5×10 -6 During Torr, the Hall ion source is used to feed argon gas, the anode voltage of the ion source is controlled to 120V, the anode current is controlled to 4A, the neutralization current is controlled to 260mA, and the treatment time is 200s; using this process condition for plasma treatment, an excellent The surface cleaning effect of the cavity surface ...

Embodiment 2

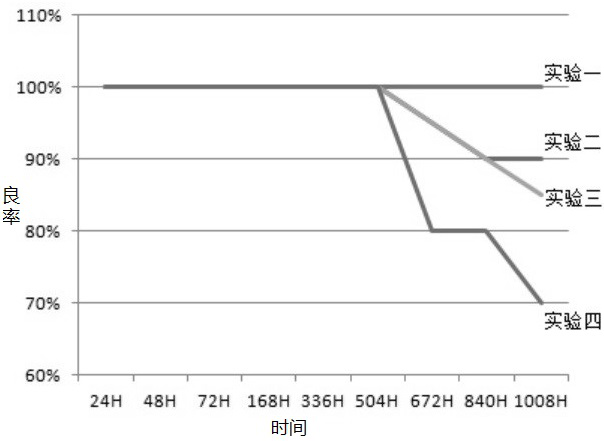

[0055] Carry out long-term aging performance test to the product of experiment, experiment is divided into four groups, and the manufacture method of four groups of experimental products is the same as embodiment 1, and difference is:

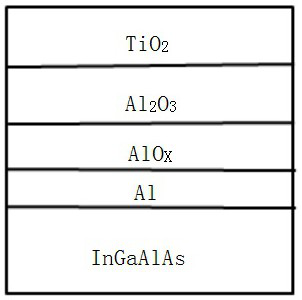

[0056] Experiment 1 is the experimental group: both the surface of the light cavity and the surface of the backlight cavity adopt the Al layer oxygen penetration process, and the film structure of the surface of the light cavity is Al / AlO X / Al 2 o 3 / TiO 2 , the film structure of the backlight cavity surface is Al / AlO X / Al 2 o 3 / Si / Al 2 o 3 / Si, randomly select 20pcs chips;

[0057] Experiment 2 is the control group: the Al layer oxygen permeation process is adopted on the surface of the light cavity, and the film structure of the surface of the light cavity is Al / AlO X / Al 2 o 3 / TiO 2 , the film structure of the backlight cavity surface is Al 2 o 3 / Si / Al 2 o 3 / Si, randomly select 20pcs chips;

[0058] Experiment 3 is the ...

Embodiment 3

[0063] The product of experiment is carried out SEM topography analysis, experiment is divided into two groups, and the preparation method of two groups of experimental products is the same as embodiment 1, and difference is:

[0064] Experiment 1 is the experimental group: both the surface of the light cavity and the surface of the backlight cavity adopt the Al layer oxygen penetration process, and the film structure of the surface of the light cavity is Al / AlO X / Al 2 o 3 / TiO 2 , the film structure of the backlight cavity surface is Al / AlO X / Al 2 o 3 / Si / Al 2 o 3 / Si, randomly select 20pcs chips;

[0065] Experiment 2 is the control group; neither the surface of the light cavity nor the surface of the backlight cavity adopts the Al layer oxygen penetration process, and the film structure of the surface of the light cavity is Al 2 o 3 / TiO 2 , the film structure of the backlight cavity surface is Al 2 o 3 / Si / Al 2 o 3 / Si, randomly select 20pcs chips;

[0066...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com