Inorganic nano MoSx/gamma-MnS composite material as well as preparation method and application thereof

A composite material and inorganic nanotechnology, applied in the field of anti-tumor, to achieve high light-to-heat conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The invention provides an inorganic nano-MoS x The preparation method of / γ-MnS composite material, preparation method comprises the steps:

[0038] Step S1, sodium molybdate (Na 2 MoO 4 ), manganese sulfate (MnSO 4 ) and cysteine (L-Cys) were added into water and dissolved respectively to obtain sodium molybdate solution, manganese sulfate solution and cysteine solution;

[0039] Step S2, mixing and stirring sodium molybdate solution, manganese sulfate solution and cysteine solution to obtain a mixed solution;

[0040] Step S3, put the mixed solution into a polytetrafluoroethylene reactor for hydrothermal reaction, after the hydrothermal reaction, cool to room temperature, centrifuge and wash to obtain inorganic nano-MoS x / γ-MnS heterojunction composite material (hereinafter abbreviated as MoS x / γ-MnS).

[0041] Specifically, in the above step S1, the molar ratio of sodium molybdate, manganese sulfate and cysteine is 2-3:1-2:8-13. Preferably, the molar ...

Embodiment 1

[0081] This embodiment provides an inorganic nano-MoS x The preparation method of / γ-MnS composite material, preparation method comprises the steps:

[0082] (1) 0.1g (0.4856mmol) sodium molybdate (Na 2 MoO 4 ), 0.0367g (0.2428mmol) manganese sulfate (MnSO 4 ) and 0.32g (2.6411mmol) cysteine (L-Cys) (element molar ratio Mo:Mn=2:1) were added to 3mL, 3mL, 4mL deionized water respectively, and the three solutions were mixed after ultrasonic dissolution.

[0083] (2) After the mixed solution was magnetically stirred at room temperature for 30 minutes, the mixed solution was put into a polytetrafluoroethylene reactor with a volume of 50 mL, reacted at 180 ° C for 24 hours, cooled to room temperature, centrifuged at 12000 rpm for 5 minutes, and used Washed three times alternately with ionized water and ethanol to obtain black MoS x / γ-MnS heterojunction composites.

[0084] (3) Take MoS x Add 0.01g of γ-MnS heterojunction composite material to 10mL deionized water, and add...

Embodiment 2

[0086] This embodiment provides an inorganic nano-MoS x / The preparation method of γ-MnS composite material, the first two steps of its preparation method are identical with (1)-(2) in the above-mentioned embodiment 1, do not go into details here and the preparation method comprises the following steps:

[0087] (3) Take MoS x Add 0.01g of γ-MnS heterojunction composite material to 10mL deionized water, add 0.01g gelatin and 0.005g polypeptide cRGD, sonicate until completely dissolved, stir at 1000rpm at room temperature for 6h, and centrifuge at 12000rpm for 5min , washed with deionized water to remove excess gelatin to obtain MoS x / γ-MnS@Gel-cRGD nanocomposites.

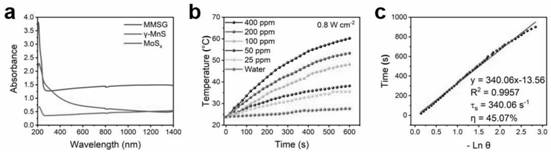

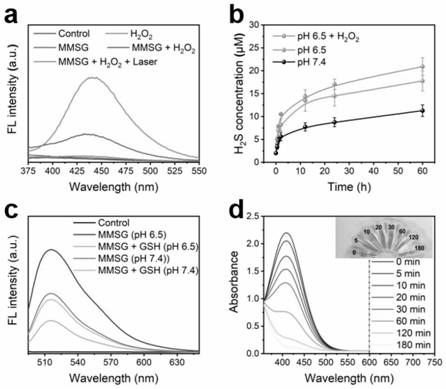

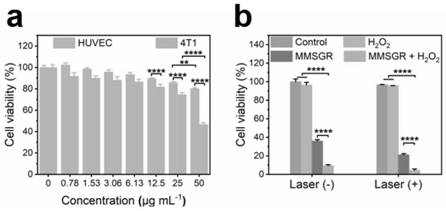

[0088] Specifically, MoS x , γ-MnS, MoS x / γ-MnS, MoS x / γ-MnS@Gel and MoS x The various related detection results of / γ-MnS@Gel-cRGD are as follows:

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com