A method for preparing sacubitril intermediate in a continuous flow microreactor

A shakubatri and micro-reactor technology, which is applied in chemical instruments and methods, chemical/physical/physical chemical reactors, organic chemical methods, etc., can solve the problems of low efficiency, low yield, low purity, etc., and achieve Good selectivity, high reaction yield and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050]

[0051] (1) Preparation of material A solution: Dissolve compound II (100 Kg, 305.42 mol, 1.0 eq.) and TEMPO (9.54 Kg, 61.06 mol, 0.20 eq.) in dichloromethane (680 Kg);

[0052] (2) Preparation of material B solution: Dissolve sodium bicarbonate (38.48 Kg, 458.12 mol, 1.5 eq.) and sodium bromide (1.88 Kg, 18.27 mol, 0.06 eq.) in water (600 Kg);

[0053] (3) Material C solution: sodium hypochlorite aqueous solution, the measured content is: 9.6%;

[0054] (4) Preparation of material D solution: In a reaction kettle, add water (200 Kg), dichloromethane (132.5 Kg), ethoxyformyl ethylene triphenylphosphine (110 Kg, 305.42 mol, 1.0 eq. ) and sodium thiosulfate (15.16 Kg, 61.08mol, 0.2 eq.), stirred and cooled to 0-5 ℃ for later use;

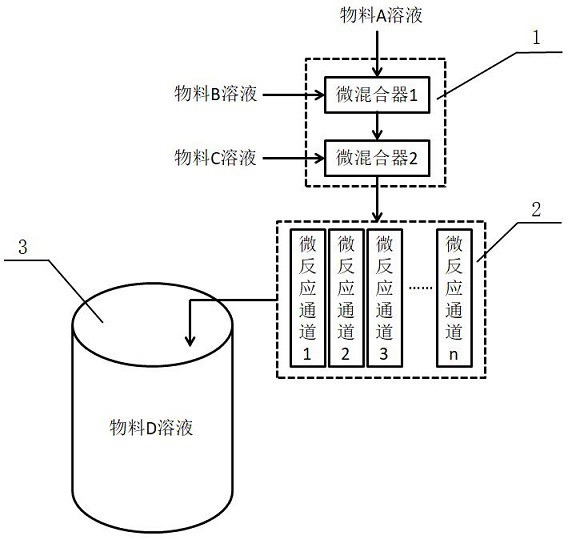

[0055] (5) Mix the material A solution and the material B solution in the micro-mixer 1 first, the residence time is 4-6 s, and then mix with the material C solution in the micro-mixer 2, the residence time is 3-5 s, and then Enter the mi...

Embodiment 2

[0060]

[0061] (1) Preparation of material A solution: Dissolve compound II (100 Kg, 305.42 mol, 1.0 eq.) and TEMPO (2.39 Kg, 15.27 mol, 0.05 eq.) in dichloromethane (680 Kg);

[0062] (2) Preparation of material B solution: Dissolve sodium carbonate (32.36 Kg, 305.37 mol, 1.0 eq.) and sodium bromide (1.57 Kg, 15.225 mol, 0.05 eq.) in water (600 Kg);

[0063] (3) Material C solution: sodium hypochlorite aqueous solution, the measured content is: 8.3%;

[0064] (4) Preparation of material D solution: In a reaction kettle, add water (200 Kg), dichloromethane (132.5 Kg), ethoxyformyl ethylene triphenylphosphine (94 Kg, 259.61 mol, 0.85 eq. ) and sodium thiosulfate (15.16 Kg, 61.08mol, 0.2 eq.), stirred and cooled to 0-5 ℃ for later use;

[0065] (5) Mix the material A solution and the material B solution in the micro-mixer 1 first, the residence time is 3-5 s, and then mix with the material C solution in the micro-mixer 2, the residence time is 2-6 s, and then Enter the mic...

Embodiment 3

[0070]

[0071] (1) Preparation of material A solution: Dissolve compound II (100 Kg, 305.42 mol, 1.0 eq.) and TEMPO (23.85 Kg, 152.65 mol, 0.5 eq.) in isopropyl acetate (700 Kg);

[0072] (2) Preparation of material B solution: sodium bicarbonate (30.79 Kg, 366.50 mol, 1.2 eq.), sodium carbonate (9.71 Kg, 91.61 mol, 0.3 eq.) and sodium bromide (15.67 Kg, 152.27 mol, 0.5 eq.) dissolved in water (800 Kg);

[0073] (3) Material C solution: sodium hypochlorite aqueous solution, the measured content is 8.3%;

[0074] (4) Preparation of material D solution: In a reaction kettle, add water (300 Kg), isopropyl acetate (135 Kg), ethoxyformyl ethylene triphenylphosphine (221.37 Kg, 610.83 mol, 2.0 eq .) and sodium thiosulfate (15.16 Kg, 61.08 mol, 0.2 eq.), stirred and cooled to 0-5 ℃ for later use;

[0075] (5) Mix the material A solution and the material B solution in the micro-mixer 1 first, the residence time is 1-5 s, and then mix with the material C solution in the micro-mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com