Preparation method and application of cobalt-based metal organic framework derived magnetic carbon composite material

A technology of organic framework and composite materials, which is applied in the fields of alkali metal compounds, chemical instruments and methods, alkali metal oxides/hydroxides, etc., and can solve the problems of high production cost of carbon nanotubes, unsatisfactory adsorption effect, and difficult regeneration of activated carbon, etc. problem, to achieve the effect of sufficient source of raw materials, good desorption capacity and recycling capacity, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

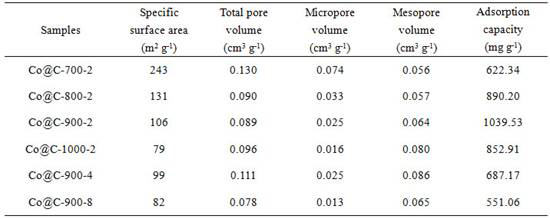

[0048] Preparation of cobalt-based metal-organic framework-derived magnetic carbon composite material Co@C-700-2

[0049] 1) Dissolve 0.1mmol methylpyrogallol calix[4]arene and 0.3mmol cobalt nitrate hexahydrate in 12mL acetonitrile aqueous solution (the volume ratio of acetonitrile and water is 5:1), and then add 30 μL triethyl ether dropwise Amine, shake evenly to obtain mixed solution A, place the scintillation vial containing mixed solution A in an oven at 80°C for 24 hours, cool naturally to room temperature, filter, wash with acetonitrile and dry to obtain cobalt-based metal organic Skeleton compound Co-MONCs;

[0050] 2) Put the crucible containing cobalt-based metal-organic framework compound Co-MONCs into a tube furnace for calcination at a calcination temperature of 700 °C for 2 h, wherein the tube furnace maintained a heating rate of 5 °C / min, nitrogen gas was introduced during the working process of the tube furnace, and the rate of nitrogen gas feeding was kept ...

Embodiment 2

[0052] Preparation of cobalt-based metal-organic framework-derived magnetic carbon composite material Co@C-800-2

[0053] 1) Dissolve 0.1mmol methylpyrogallol calix[4]arene and 0.3mmol cobalt nitrate hexahydrate in 12mL acetonitrile aqueous solution (the volume ratio of acetonitrile and water is 5:1), and then add 30 μL triethyl ether dropwise Amine, shake evenly to obtain mixed solution A, place the scintillation vial containing mixed solution A in an oven at 80°C for 24 hours, cool naturally to room temperature, filter, wash with acetonitrile and dry to obtain cobalt-based metal organic Skeleton compound Co-MONCs;

[0054] 2) Put the crucible containing the cobalt-based metal-organic framework compound Co-MONCs into a tube furnace for calcination at a calcination temperature of 800 °C for 2 h, wherein the tube furnace maintained a heating rate of 5 °C / min, nitrogen gas was introduced during the working process of the tube furnace, and the rate of nitrogen gas feeding was k...

Embodiment 3

[0056] Preparation of cobalt-based metal-organic framework-derived magnetic carbon composite material Co@C-900-2

[0057] 1) Dissolve 0.1mmol methylpyrogallol calix[4]arene and 0.3mmol cobalt nitrate hexahydrate in 12mL acetonitrile aqueous solution (the volume ratio of acetonitrile and water is 5:1), and then add 30 μL triethyl ether dropwise Amine, shake evenly to obtain mixed solution A, place the scintillation vial containing mixed solution A in an oven at 80°C for 24 hours, cool naturally to room temperature, filter, wash with acetonitrile and dry to obtain cobalt-based metal organic Skeleton compound Co-MONCs;

[0058] 2) Put the crucible containing the cobalt-based metal-organic framework compound Co-MONCs into a tube furnace for calcination at a calcination temperature of 900 °C for 2 h, wherein the tube furnace maintained a heating rate of 5 °C / min, nitrogen gas was introduced during the working process of the tube furnace, and the rate of nitrogen gas feeding was k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com