Preparation method of 4, 4 '-diaminodiphenyl ether

A technology of diaminodiphenyl ether and dinitrodiphenyl ether, which is applied in the field of preparation of 4,4'-diaminodiphenyl ether, can solve the problem that hydrazine hydrate is expensive, highly corrosive, highly toxic, diaminodiphenyl ether The problems of low ether yield and high requirements for reaction equipment can achieve the effects of high-efficiency photocatalytic reduction, avoiding synthesis conditions, and high-efficiency stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] Aiming at the problems of unenvironmental protection, high price or high production cost of the catalyst in the preparation process of 4,4'-diaminodiphenyl ether in the prior art, this application provides a clean, environmentally friendly, stable, efficient and green economical 4,4' -The preparation method of diaminodiphenyl ether, specifically, the embodiment of the present invention discloses a preparation method of 4,4'-diaminodiphenyl ether, comprising:

[0025] Under the catalysis of twinned zinc cadmium sulfide, 4,4'-dinitrodiphenyl ether and water undergo photocatalytic hydrogenation reaction to obtain 4,4'-diaminodiphenyl ether.

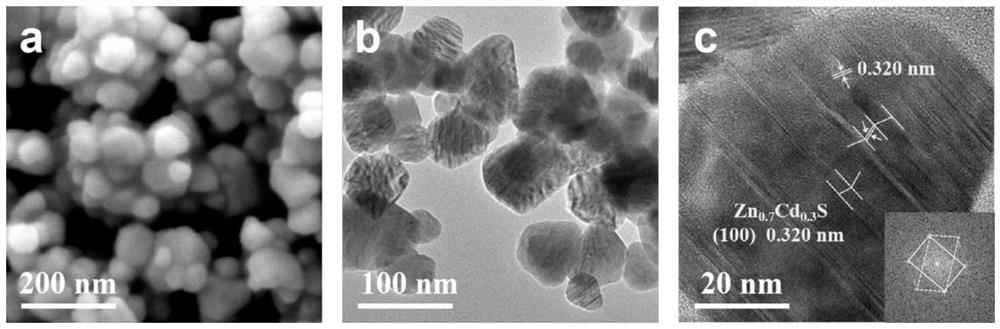

[0026] The preparation of 4,4'-diaminodiphenyl ether in this application is to use photocatalytic means, by selecting twin crystal zinc cadmium sulfide solid solution as the photocatalyst, using 4,4'-dinitrodiphenyl ether as raw material, without the need Access to extra H 2 Under conditions, water is used as a solvent to provide hyd...

Embodiment 1

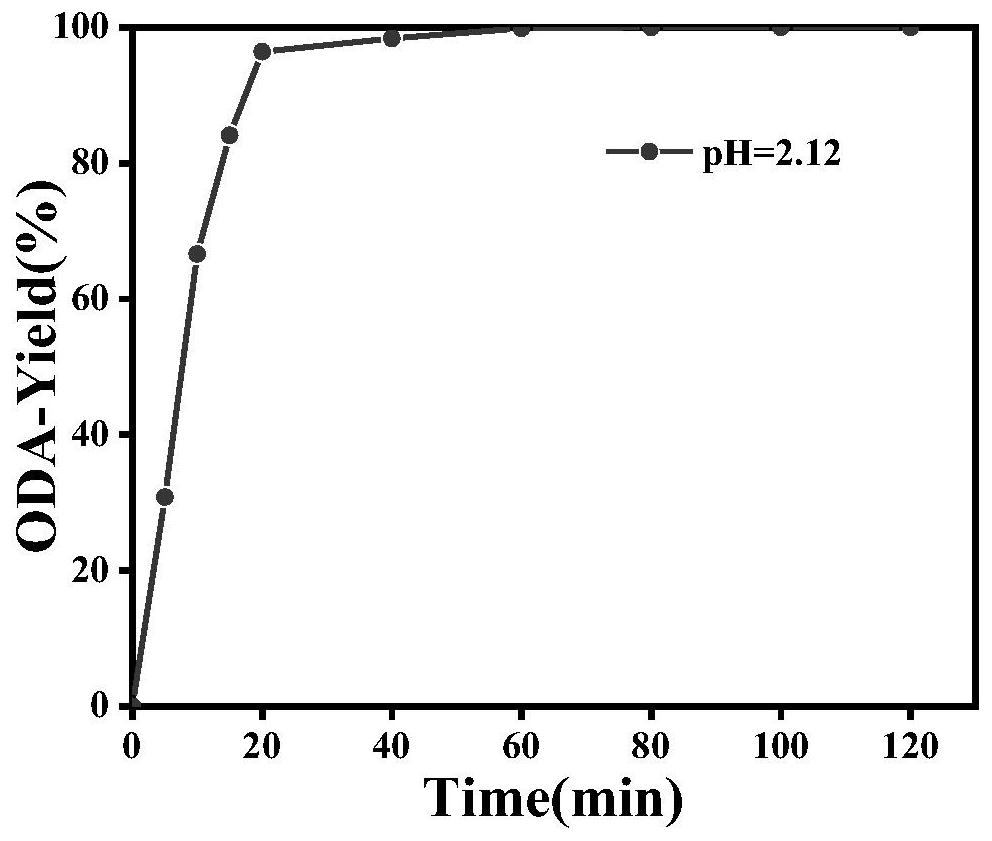

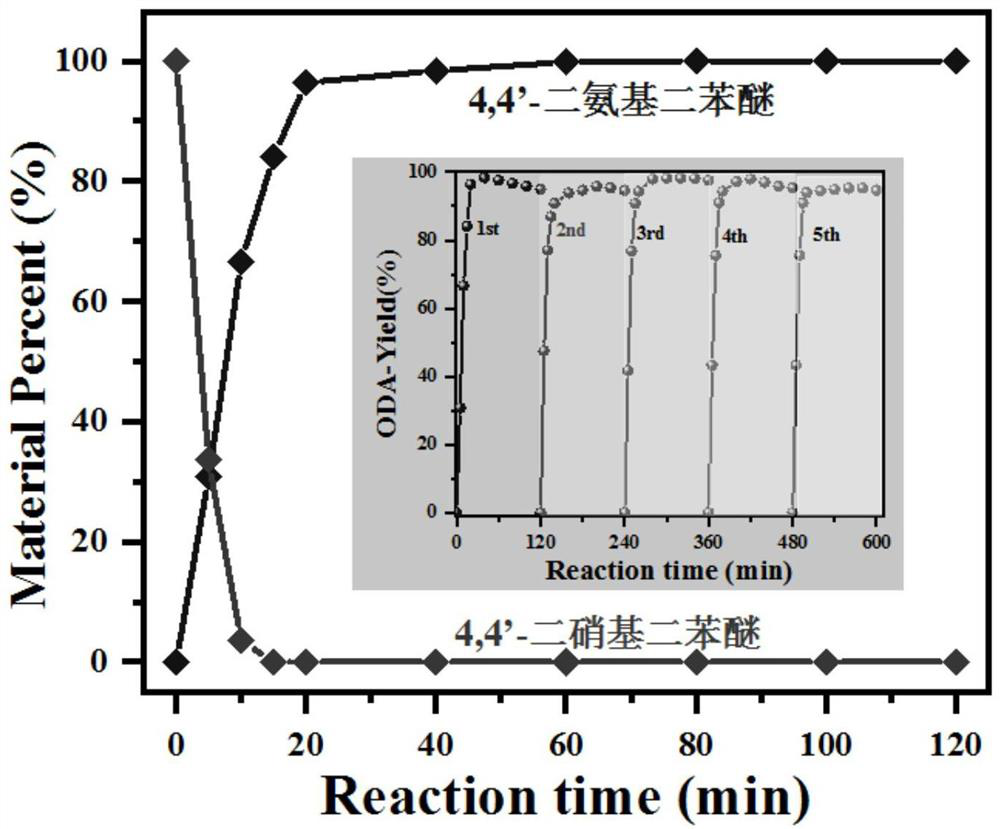

[0037] Prepare 30vol% ethanol aqueous solution: add 30mL absolute ethanol to 70mL water, and ultrasonically make it form a homogeneous solution; ② Add 5 μmol 4,4'-dinitrodiphenyl ether reaction raw materials to the 30vol% ethanol aqueous solution in step ①, 10mg twinned Zn 0.7 Cd 0.3 S catalyst, add 0.1mol L to the system -1 HCl regulates the pH of the reaction system to 2.12, and stirs for 30 minutes; ③ Seal the reactor and pass in an inert gas N 2 30min, exhaust the air in the reactor; ④ 300W xenon lamp injects visible light with a wavelength ≥ 420nm into the reactor through the top-illumination type, the reactor temperature is controlled by water circulation and condensation to 15°C, and after 40min of reaction, samples are taken and quantified by high-performance liquid chromatography, of which 4, The conversion rate of 4'-dinitrodiphenyl ether is >99%, the product yield of 4,4'-diaminodiphenyl ether is >99%, and good stability and product yield are still maintained aft...

Embodiment 2

[0042] Steps ①, ②, and ④ of this embodiment are the same as in Example 1, the difference is: step ③: seal the reactor, feed inert gas argon for 30 minutes, and discharge the air in the reactor. After 40 minutes of reaction, samples were taken and quantified by high-performance liquid chromatography, wherein the conversion rate of 4,4'-dinitrodiphenyl ether was >99%, the yield of 4,4'-diaminodiphenyl ether was >99%, and the reaction cycle was 5 times After that, good stability and product yield were still maintained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com