Polyester high stretch yarn detergent and preparation method thereof

A technology of polyester high elastic yarn and detergent, which is applied in the direction of detergent composition, detergent compounding agent, chemical instrument and method, etc., and can solve the problem of focusing on decontamination performance, antistatic performance or cleaning performance, polyester high elastic yarn Detergent selectivity fluctuations, product incompatibility and other problems, to achieve good hydrolysis stability, excellent emulsification performance, good safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

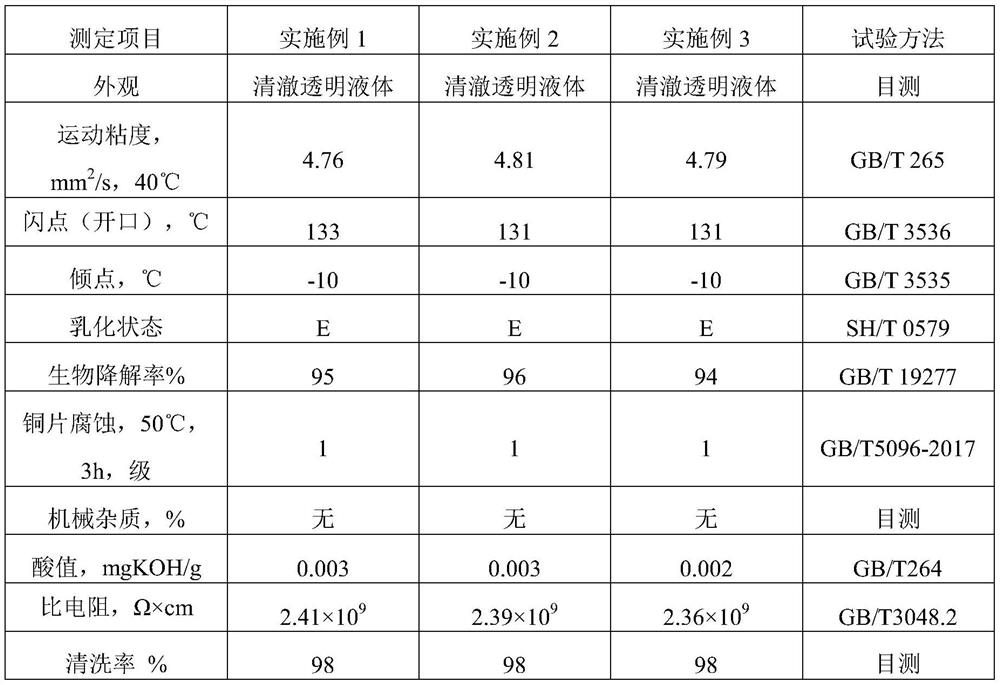

Examples

Embodiment 1

[0029]A kind of detergent for polyester high elastic yarn, made up of base oil, emulsifier, solubilizer, preservative, dispersant, bactericide, antistatic agent, wherein, described emulsifier is fatty alcohol polyoxyethylene ether; The solubilizer is polyoxyethylene fatty acid ester; the preservative is sodium benzoate; the dispersant is sodium methylenebisturate; the bactericide is polyquaternium; base ether phosphate potassium salt; the base oil is secondary hydrogenation industrial white oil. The fatty alcohol polyoxyethylene ether is obtained by the chemical reaction of fatty alcohol and polyoxyethylene ether, specifically, sodium hydroxide is used as a catalyst, and the long-chain fatty alcohol is combined with epoxy in the absence of water and oxygen. Ethane undergoes ring-opening polymerization reaction to generate fatty alcohol polyoxyethylene ether.

[0030] And, the mass percentage of the emulsifier in the polyester high elastic yarn detergent is 8%; the mass percen...

Embodiment 2

[0041] A kind of detergent for polyester high elastic yarn, made up of base oil, emulsifier, solubilizer, preservative, dispersant, bactericide, antistatic agent, wherein, described emulsifier is fatty alcohol polyoxyethylene ether; The solubilizer is polyoxyethylene fatty acid ester; the preservative is sodium benzoate; the dispersant is sodium methylenebisturate; the bactericide is polyquaternium; base ether phosphate potassium salt; the base oil is secondary hydrogenation industrial white oil. The fatty alcohol polyoxyethylene ether is obtained by the chemical reaction of fatty alcohol and polyoxyethylene ether, specifically, sodium hydroxide is used as a catalyst, and the long-chain fatty alcohol is combined with epoxy in the absence of water and oxygen. Ethane undergoes ring-opening polymerization reaction to generate fatty alcohol polyoxyethylene ether.

[0042] And, the mass percentage of the emulsifier in the polyester high elastic yarn detergent is 8.2%; the mass per...

Embodiment 3

[0053] A kind of detergent for polyester high elastic yarn, made up of base oil, emulsifier, solubilizer, preservative, dispersant, bactericide, antistatic agent, wherein, described emulsifier is fatty alcohol polyoxyethylene ether; The solubilizer is polyoxyethylene fatty acid ester; the preservative is sodium benzoate; the dispersant is sodium methylenebisturate; the bactericide is polyquaternium; base ether phosphate potassium salt; the base oil is secondary hydrogenation industrial white oil. The fatty alcohol polyoxyethylene ether is obtained by the chemical reaction of fatty alcohol and polyoxyethylene ether, specifically, sodium hydroxide is used as a catalyst, and the long-chain fatty alcohol is combined with epoxy in the absence of water and oxygen. Ethane undergoes ring-opening polymerization reaction to generate fatty alcohol polyoxyethylene ether.

[0054] And, the mass percentage of the emulsifier in the polyester high elastic yarn detergent is 8.6%; the mass per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com