Battery aluminum alloy foil, preparation method thereof and battery current collector

A technology of aluminum alloy foil and battery assembly, applied in the direction of battery electrodes, metal rolling, electrode carriers/collectors, etc., to achieve the effects of refining the casting structure grains, good plate shape, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

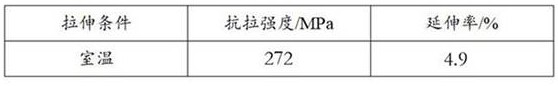

Embodiment 1

[0068] 1100H18 produce high-performance single light cell foil, thickness 0.012 mm finished, finished width 1060mm.

[0069] Its production process comprising: melting → casting → sawing and milling treatment → hot rolling → homogenizing → cold rolling → annealing → cold rolling → intermediate → rough rolling in finishing rolling → → → bonding roll slitting.

[0070] Melting: The raw material 90 tons pure aluminum ingot (purity 99.7%), 900kg iron (Al-Fe80%), 135kg agent copper (Al-Cu80%) and titanium 16kg agent (Al-Ti80%), smelting, melting temperature 730 ~ 750 ℃, by electromagnetic stirring three times, each time through positive and negative, positive rotation of three cycles, each cycle 8min.

[0071] Casting: casting from the holding furnace the temperature of 690 ~ 710 ℃, the filter plate heating temperature 760 ~ 790 ℃, T-type casting launder melt temperature of 680 ~ 700 ℃, the casting speed of 60mm / min. Semi-continuous casting of flat ingot specifications for 560mm * ...

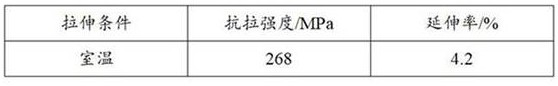

Embodiment 2

[0083] Similar to Example 1, except that only:

[0084] a, the equalization process: the first uniform heating temperature 550 ℃, 8H holding time; second stage homogenization heating temperature 440 ℃, incubated 0.5h.

[0085] b, hot rolling: rough rolling final pass rolling speed of 2m / s, final pass processing rate of 40%. HRC thickness of 5.0mm, coiling temperature 250 ℃.

[0086] C, chill roll crown 28% after the intermediate annealing roughness Ra 0.28um, per pass working ratio of 50%, the temperature of the metal crimp 110 ℃.

[0087] d, foil rolling: rolling foil 2 passes (roughing) roll crown 35%, the roughness Ra 0.20um; 3,4 foil pass rolling (intermediate rolling) roll crown 50%, the roughness Ra 0.16um ; 5 times the foil rolling (finishing) roll crown 60%, the roughness Ra 0.12um.

[0088] e, spectral component alloy foil as the content percentage: Si: 0.04%, Fe: 0.75%, Cu: 0.17%, Mn: 0.008%, Mg: 0.005%, Zn: 0.005%, Ti: 0.017%, Al: 99.00% the rest is impurity elements....

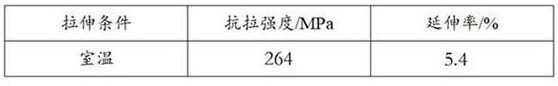

Embodiment 3

[0093] Similar to Example 1, except that only:

[0094] a, the equalization process: the first uniform heating temperature 540 ℃, holding time 6H; second stage homogenization heating temperature 420 ℃, incubated 2h.

[0095] b, hot rolling: rough rolling final pass rolling speed 1m / s, final pass processing was 60%. HRC thickness of 4.0mm, coiling temperature 280 ℃.

[0096] C, chill roll crown 25% after the intermediate annealing roughness Ra 0.2um, per pass working ratio of 50%, the temperature of the metal crimp 100 ℃.

[0097] d, foil rolling: rolling foil 2 passes (roughing) roll crown 35%, the roughness Ra 0.17um; 3,4 foil pass rolling (intermediate rolling) roll crown 45%, the roughness Ra 0.14um ; 5 times the foil rolling (finishing) roll crown 55%, the roughness Ra 0.12um.

[0098] e, spectral content of the ingot alloy composition percentages: Si: 0.03%, Fe: 0.84%, Cu: 0.10%, Mn: 0.005%, Mg: 0.003%, Zn: 0.003%, Ti: 0.016%, Al: 99.00 %, the remainder being impurities.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com