Boron carbide/carbon composite material with controllable boron carbide structure and preparation method and application thereof

A carbon composite material and boron carbide technology, applied in the field of ceramic materials, can solve the problems of low toughness, easy fracture, and high brittleness of boron carbide ceramics, achieve good material hardness and toughness, speed up production cycle, and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The boron carbide powder and the yttrium oxide additive are fully mixed according to the mass ratio of 95:5, and then put into a stainless steel mold for cold pressing, the pressure is 20MPa, and the holding time is 1min. The cold-pressed block was packaged in a graphite tank, and then the graphite tank was packaged in a corundum ark, and the temperature was raised to 1550 °C at a rate of 3 °C / min using a muffle furnace, and then kept for 2 hours. After cooling down to normal temperature, the microscopic confocal Raman spectrum of the bulk material in the graphite tank was measured.

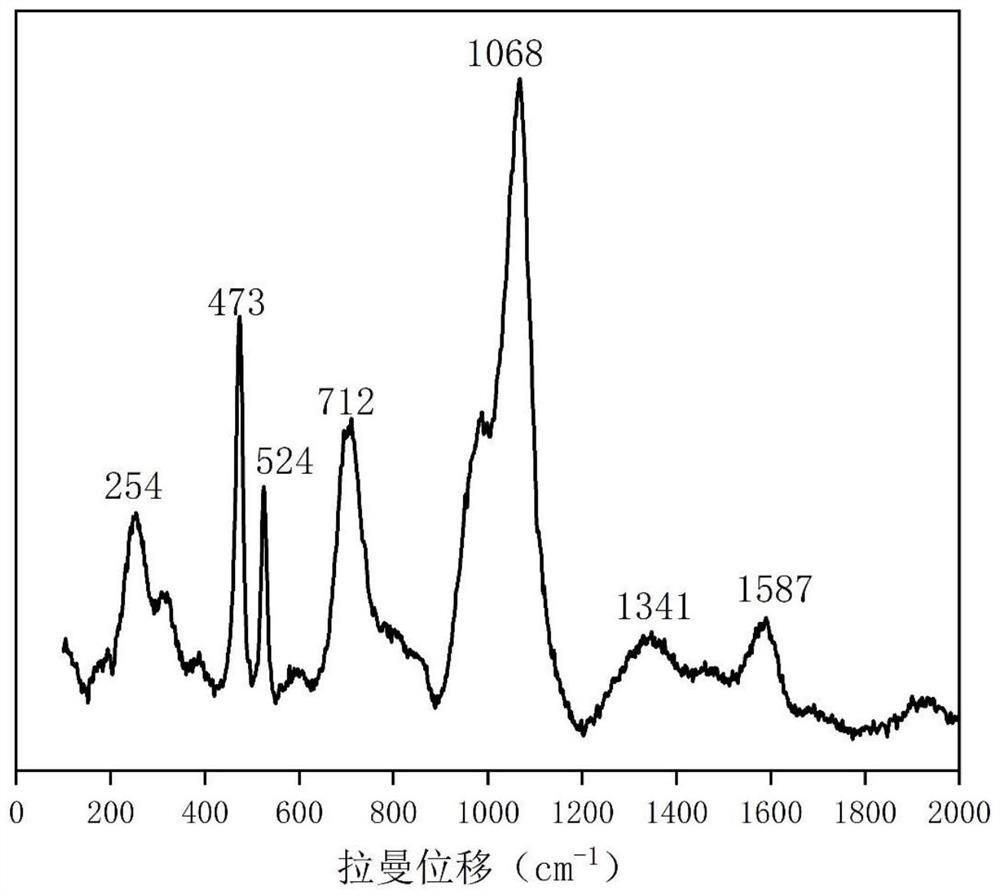

[0049] like Figure 5 As shown, the relative ratio of Raman peak intensities of triatomic chain stretching vibration, icosahedral rocking vibration, icosahedral breathing vibration, D peak and G peak is 0.61:0.38:1.00:2.16:1.75. and figure 2 Compared with the boron carbide powder without high temperature treatment, Figure 5 The relative peak intensity ratios of triatomic chain stretch...

Embodiment 2

[0053] The boron carbide powder and the barium titanate additive are fully mixed according to the mass ratio of 95:5, and then put into a stainless steel mold for cold pressing, the pressure is 20MPa, and the holding time is 1min. The cold-pressed block was packaged in a graphite tank, and then the graphite tank was packaged in a corundum ark, and the temperature was raised to 1550 °C at a rate of 3 °C / min using a muffle furnace, and then kept for 2 hours. After cooling down to normal temperature, the microscopic confocal Raman spectrum of the bulk material in the graphite tank was measured.

[0054] like Figure 7 As shown, the relative ratios of the Raman peak intensities of the three-atom chain stretching vibration, icosahedral rocking vibration, icosahedral breathing vibration, D peak and G peak are 0.58:0.35:1.00:1.62:1.14. and figure 2 Compared with the boron carbide powder, Figure 7 The relative peak intensity ratios of triatomic chain stretching and icosahedral sw...

Embodiment 3

[0057] After the boron carbide powder and magnesium oxide additive are fully mixed according to the mass ratio of 95:5, they are put into a stainless steel mold for cold pressing, the pressure is 20MPa, and the pressure holding time is 1min. The cold-pressed block was packaged in a graphite tank, and then the graphite tank was packaged in a corundum ark, and the temperature was raised to 1550 °C at a rate of 3 °C / min using a muffle furnace, and then kept for 2 hours. After cooling down to normal temperature, the microscopic confocal Raman spectrum of the bulk material in the graphite tank was measured.

[0058] like Figure 8 As shown, the relative ratio of the Raman peak intensities of the triatomic chain stretching vibration, icosahedral rocking vibration, icosahedral breathing vibration, D peak and G peak is 0.82:0.41:1.00:3.74:2.02. and figure 2 Compared with the boron carbide powder, Figure 8 The relative peak intensities of triatomic chain stretching and icosahedral...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Half width | aaaaa | aaaaa |

| Half width | aaaaa | aaaaa |

| Average size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com